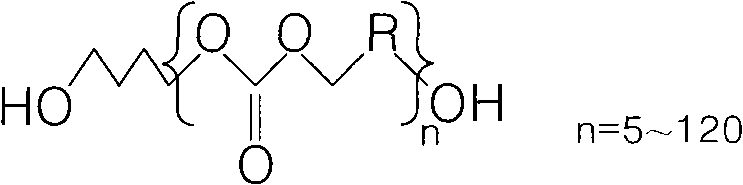

Poly (alkene carbonate) diol-polylactic acid segmented copolymer and preparation method thereof

A technology of polycarbonate diol and block copolymer, which is applied in the field of preparation of polycarbonate diol-polylactic acid block copolymer, which can solve the problem of limited application range and long PLLA degradation cycle and other issues to achieve the effect of simplifying the process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Put 0.1g of polyethylene carbonate diol with a molecular weight of 1000g / mol, 100g of lactide and 0.01g of stannous octoate fully dried in advance into a 250ml narrow-mouth bottle, vacuumize to below 30Pa, and fill it into a dry High-purity nitrogen, and then repeat the vacuuming-nitrogen filling operation for more than 5 times, and finally vacuumize to 10Pa, seal the reaction bottle, heat up to 180°C, and react for 6 hours to finally obtain polycarbonate with a molecular weight of 86Kg / mol and a molecular weight distribution of 1.99. Ethylene glycol-polylactic acid block copolymer.

Embodiment 2

[0021] 20.0g of polyethylene carbonate diol with a molecular weight of 1200g / mol, 30.0g of polypropylene carbonate diol with a molecular weight of 500g / mol, 100.0g of lactide and 0.015g of dibutyl oxidation Put the tin into a 250ml narrow-mouth bottle, vacuumize it to below 30Pa, fill it with dry high-purity nitrogen, then repeat the vacuumize-nitrogen filling operation 5 times, and finally vacuumize it to 12Pa, seal the reaction bottle, and raise the temperature to 160°C. After reacting for 12 hours, a polycarbonate diol-polylactic acid block copolymer with a molecular weight of 58Kg / mol and a molecular weight distribution of 1.71 was finally obtained.

Embodiment 3

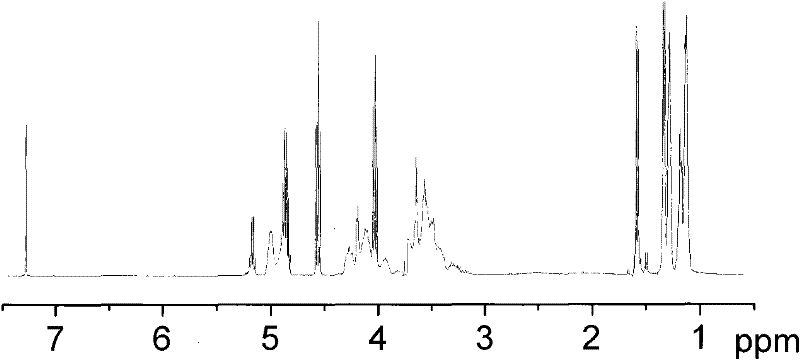

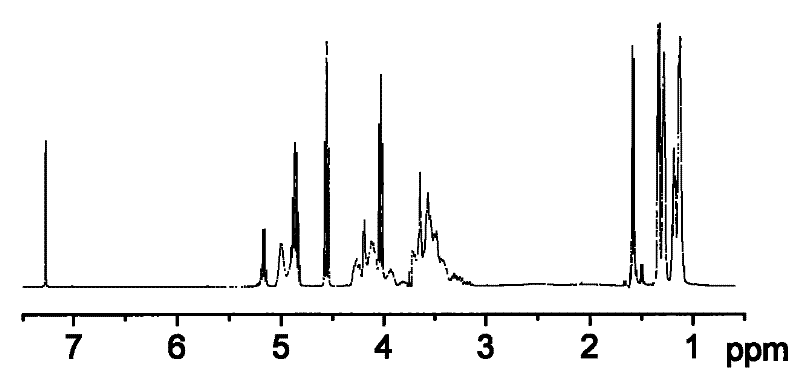

[0023] 30.0g of polyethylene carbonate diol with a molecular weight of 2000g / mol, 30.0g of polypropylene carbonate diol with a molecular weight of 1500g / mol, and 40.0g of polybutylene carbonate with a molecular weight of 2000g / mol were fully dried in advance. Put alcohol, 100g lactide, 0.001g dibutyltin oxide, and 0.001g tributyltin oxide into a 250ml narrow-mouth bottle, vacuumize to less than 30Pa, fill with dry high-purity nitrogen, and then repeat vacuuming — Nitrogen filling operation 6 times, finally vacuumize to 5Pa, seal the reaction bottle, heat up to 150°C, react for 16 hours, and finally obtain polycarbonate diol-polylactic acid block with a molecular weight of 66Kg / mol and a molecular weight distribution of 1.53 copolymer. The NMR spectrum of the obtained copolyester is as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com