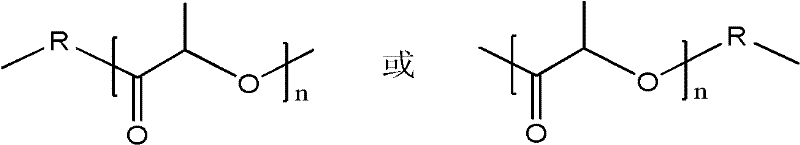

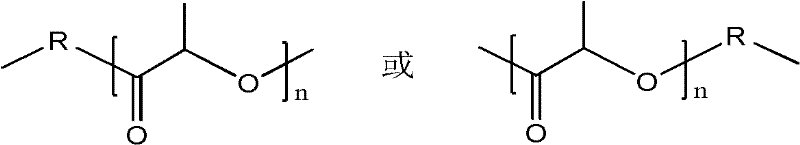

Unsaturated polylactic acid block copolymer and preparation method thereof

A block copolymer, unsaturated technology, applied in the field of unsaturated polylactic acid block copolymer and its preparation, can solve the problem of polylactic acid sheet tearing, uneven wall thickness of thermoformed products, shape of molded products can not be the same, etc. problems, to achieve the effect of improving processing performance, increasing melt strength, and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

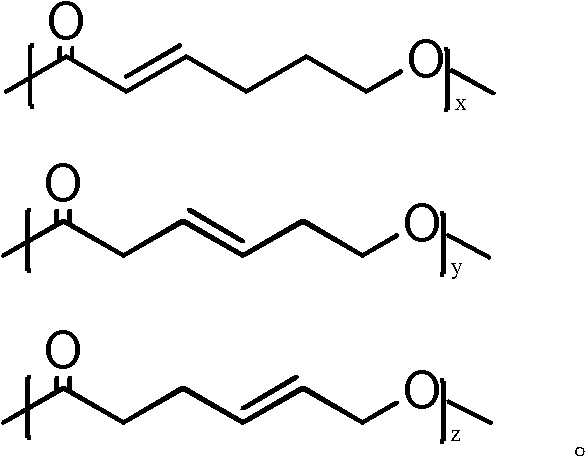

Method used

Image

Examples

Embodiment 1

[0025] Put 0.1g of fully dried 6,7-dihydro-5H-oxheptan-2-one (DHO) and 0.01g of stannous octoate into a reaction flask with 10ml of toluene, vacuumize it to below 30Pa, and fill it with Dry high-purity nitrogen, then repeat vacuuming and nitrogen filling operations 5 times, and finally vacuumize to 5Pa, seal the reaction bottle, and place it at 50°C for 1 hour of reaction; add 100g of lactide to the reacted product, repeat pumping Vacuum and nitrogen filling operation 10 times, then evacuate to 5Pa and seal the reaction bottle, continue to react for 48 hours, the reaction product is dissolved and precipitated, filtered and dried, and finally unsaturated polylactic acid with a molecular weight of 78Kg / mol and a molecular weight distribution of 1.81 is obtained. block copolymers.

Embodiment 2

[0027] Put 100g of fully dried 6,7-dihydro-5H-oxoheptan-2-one (DHO) and 0.01g of tin protochloride into a 250ml reaction flask filled with 100ml of chloroform, and evacuate to below 30Pa , filled with dry high-purity nitrogen, then repeated vacuuming and nitrogen filling operations 6 times, finally vacuumed to 5Pa, sealed the reaction bottle, and placed it at 40°C for 8 hours; Ester, repeat vacuuming and nitrogen filling operation 8 times, then vacuumize to 5Pa and seal the reaction bottle, continue to react for 5 hours, the reaction product is filtered and dried after dissolving and precipitating, and finally obtains a compound with a molecular weight of 70Kg / mol and a molecular weight distribution of 1.36. Unsaturated polylactic acid block copolymer.

Embodiment 3

[0029] 5 g of well-dried 6,7-dihydro-5H-oxahept-2-one (DHO), 45 g of well-dried 6,7-dihydro-3H-oxahept-2-one (DHO2) and 0.015 g of dihydrogen Put butyltin oxide into a 250ml reaction bottle containing 50ml tetrahydrofuran, vacuumize it to below 30Pa, fill it with dry high-purity nitrogen, then repeat the vacuumization and nitrogen filling operation 6 times, and finally vacuumize it to 5Pa, seal the reaction bottle, placed at 30 ° C for 10 hours; add 100 g of lactide to the reacted product, repeat vacuuming and nitrogen filling operations 6 times, and finally vacuumize to 5 Pa and seal the reaction bottle, continue to react for 36 hours, the reaction product After being dissolved and precipitated, it was filtered and dried to finally obtain an unsaturated polylactic acid block copolymer with a molecular weight of 73K g / mol and a molecular weight distribution of 1.92.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com