H13 die steel and preparation method thereof

A technology for die steel and molten steel, which is applied in the field of wear-resistant materials, can solve the problems of high addition of precious alloy elements, low material utilization rate and high production cost, and achieve the effects of shortening production cycle, improving mechanical properties and improving hardenability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

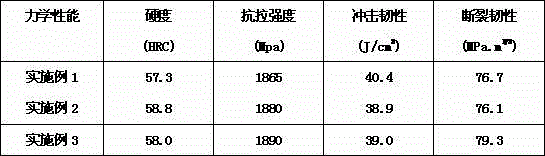

Examples

Embodiment 1

[0046] Using 5000 kg medium frequency induction furnace to smelt H13 steel, the specific process steps are:

[0047] 1) First mix and heat scrap steel, carbon ferrochrome, low carbon ferrochrome, tungsten slag ferroalloy and ferromolybdenum. When the temperature of molten steel reaches 1558°C, add ferrosilicon and ferromanganese, then add metal aluminum and ferrovanadium in sequence, and the furnace After the pre-adjusted composition is qualified, the temperature of molten steel is raised to 1647°C, and ferro-titanium and nitrogen-containing ferromanganese are added in sequence, and then released from the furnace;

[0048] 2) When the molten steel enters 30-50% of the ladle, ferron-boron and yttrium-based rare earth with a particle diameter of 1.5-3.5 mm are wrapped with a steel plate with a thickness of less than 0.5 mm, and then rushed into the ladle with the molten steel;

[0049] 3) When the temperature of the molten steel reaches 1518°C, pour the molten steel dire...

Embodiment 2

[0052] Using 5000 kg medium frequency induction furnace to smelt H13 steel, the specific process steps are:

[0053] 1) First mix and heat scrap steel, carbon ferrochrome, low carbon ferrochrome, tungsten slag ferroalloy and ferromolybdenum. When the temperature of molten steel reaches 1561℃, add ferrosilicon and ferromanganese, then add metal aluminum and ferrovanadium in turn, and the furnace After the pre-adjusted composition is qualified, the temperature of the molten steel is raised to 1604°C, and ferro-titanium and nitrogen-containing ferromanganese are added in sequence, and then released from the furnace;

[0054] 2) When the molten steel enters 30-50% of the ladle, ferron-boron and yttrium-based rare earth with a particle diameter of 1.5-3.5 mm are wrapped with a steel plate with a thickness of less than 0.5 mm, and then rushed into the ladle with the molten steel;

[0055] 3) When the temperature of the molten steel reaches 1491°C, pour the molten steel direc...

Embodiment 3

[0058] Using 10,000 kg power frequency induction furnace to smelt H13 steel, the specific process steps are:

[0059] 1) Firstly, scrap steel, carbon ferrochrome, low-carbon ferrochrome, tungsten slag ferroalloy and ferromolybdenum are mixed and heated and melted. When the temperature of molten steel reaches 1556°C, ferrosilicon and ferromanganese are added, and then metal aluminum and ferrovanadium are added in sequence. After the pre-adjusted composition is qualified, the temperature of the molten steel is raised to 1630°C, and ferro-titanium and nitrogen-containing ferromanganese are added in sequence, and then released from the furnace;

[0060] 2) When the molten steel enters 30-50% of the ladle, ferron-boron and yttrium-based rare earth with a particle diameter of 1.5-3.5 mm are wrapped with a steel plate with a thickness of less than 0.5 mm, and then rushed into the ladle with the molten steel;

[0061] 3) When the temperature of the molten steel reaches 1505°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com