Solar cell and manufacturing method thereof

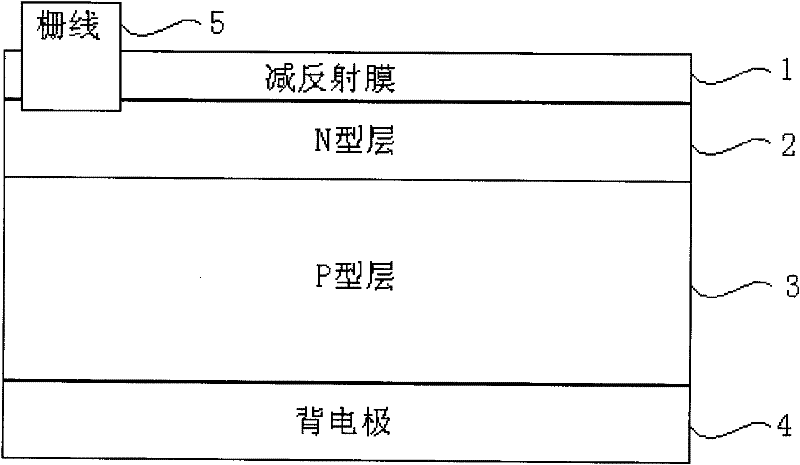

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of low efficiency of solar cells, reduced passivation effect, hydrogen atom escape, etc., to achieve firm combination, passivation Good chemical effect and high treatment temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

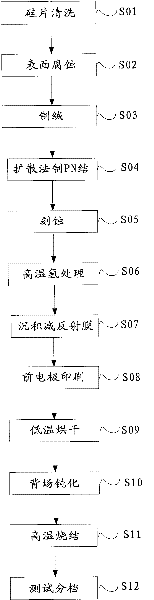

[0023] like image 3 As shown, the embodiment of the present invention provides a solar cell manufacturing method (taking the manufacturing method of a crystalline silicon solar cell as an example), which includes the following steps:

[0024] S01, silicon wafer (solar cell substrate) cleaning: clean the bare silicon wafer;

[0025] S02. Surface corrosion: use 10-30% alkali solution to corrode silicon wafers at 80-100°C for 0.5-1min to remove oil stains, cutting damage layers, etc., and the corrosion rate can reach 6-10μm / min.

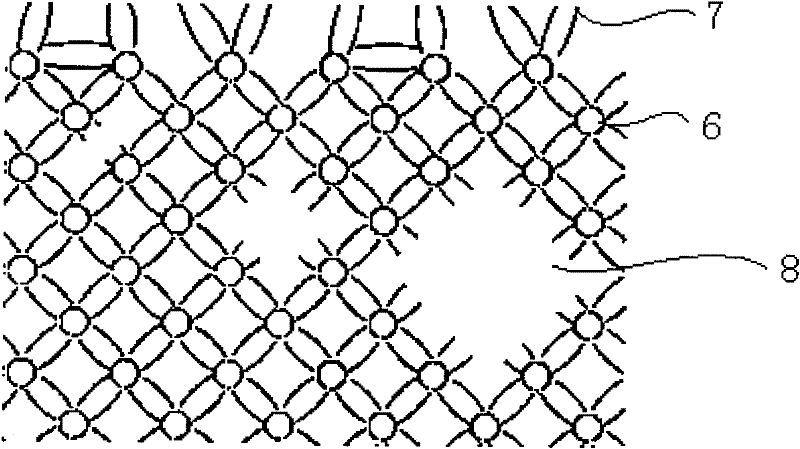

[0026] S03. Texturing: Form a textured surface (similar to an inverted pyramid-shaped surface texture) on the surface of the silicon wafer by mechanical grooving, chemical etching, reactive ion etching, laser grooving, etc., to reduce surface reflection loss.

[0027] S04, PN junction by diffusion method: Transport the carrier gas carrying the required doped impurities to the surface of the silicon wafer, diffuse the impurities to a depth of about sev...

Embodiment 2

[0037] like image 3 As shown, the embodiment of the present invention provides a solar cell manufacturing method (taking the manufacturing method of a crystalline silicon solar cell as an example), which includes the following steps:

[0038] S01, silicon wafer (solar cell substrate) cleaning: clean the bare silicon wafer;

[0039] S02. Surface corrosion: use 10-30% alkali solution to etch the silicon wafer at 80-100° C. for 0.5-1 min.

[0040] S03. Texturing: forming a textured surface (similar to an inverted pyramid-shaped surface texture) on the surface of the silicon wafer by mechanical grooving, chemical etching, reactive ion etching, laser grooving and other methods.

[0041] S04, PN junction by diffusion method: Transport the carrier gas carrying the required doped impurities to the surface of the silicon wafer, diffuse the impurities to a depth of about several hundred nanometers, and then perform high temperature treatment to continue to diffuse the impurity atoms i...

Embodiment 3

[0051] The solar cell manufacturing method of this embodiment is similar to the above embodiment, the difference is:

[0052] In the hydrogen treatment step (S06), the chamber is evacuated to 0.5 Pa, and hydrogen gas (that is, hydrogen-containing gas) with a flow rate of 8000 sccm is introduced, and the pressure is controlled at 500 Pa, heated to 1500 ° C and treated for 10 s;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com