Preparation method of magnetic compound nanometer Fe3O4 flocculating agent and water treatment application

A magnetic composite nano, iron oxide technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

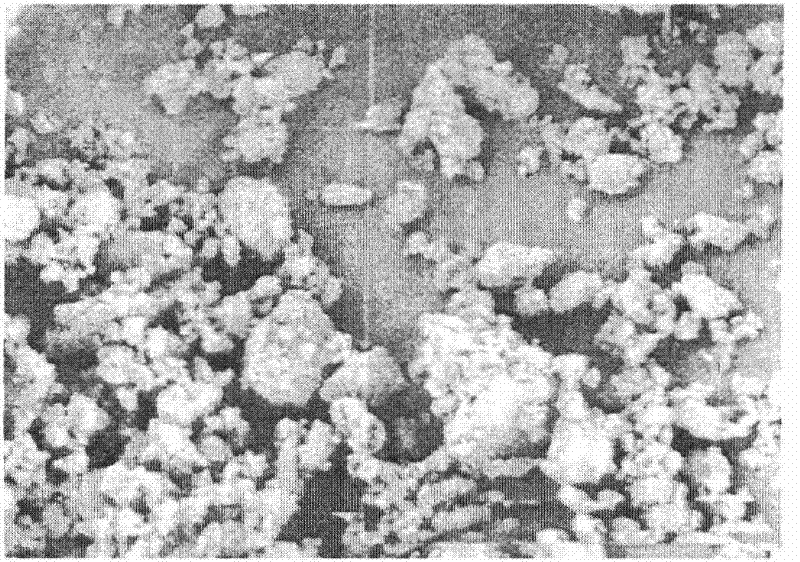

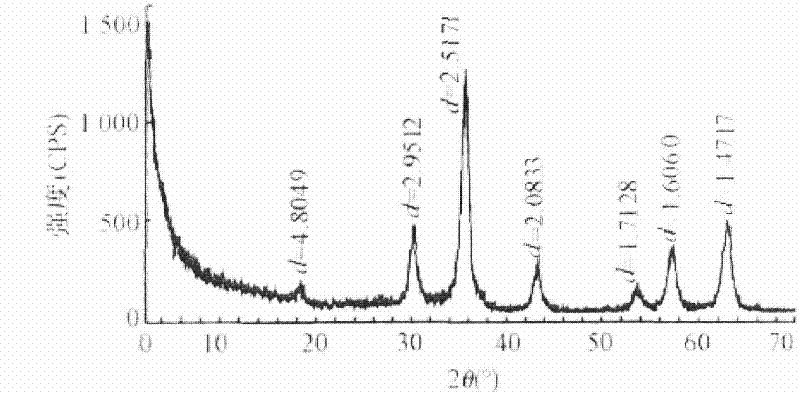

[0021] Magnetic Composite Nano Fe 3 o 4 Preparation of flocculant

[0022] (1) Weigh 0.01mol / L FeCl 2 4H 2 O and 0.02mol / L FeCl 3 ·6H 2 O was poured into the four-necked flask reactor, and 200ml of ultrapure water was added;

[0023] (2) in N 2 Under protective conditions, add 50ml of concentrated ammonia water with a mass fraction of 25% to 28% until the pH value of the system is >10;

[0024] (3) After reacting to black, add Al according to the molar ratio (Al / Fe) of the added aluminum atom to the iron atom in the synthesis system of 0.5 2 (SO 4 ) 3 18H 2 O, raise the temperature to 50°C for 30 minutes;

[0025] (4) The temperature was raised to 80° C., and reacted for 1 hour at a stirring speed of 1000 r / min;

[0026] (5) Separate the black solid with a strong magnet, wash it alternately with ultrapure water and absolute ethanol until neutral, dry it in vacuum at 70°C for 12 hours, and grind to obtain the magnetic composite nano-Fe 3 o 4 flocculant.

Embodiment 2

[0028] Magnetic Composite Nano Fe 3 o 4 Flocculant treatment of steelmaking wastewater and separation with high-efficiency magnetic separation device

[0029] According to the dosage of 100mg / L, the magnetic composite nano-iron oxide flocculant is added to the steelmaking wastewater, stirred quickly at the speed of 300r / min for 2min, then stirred slowly at the speed of 40r / min for 10min, and then the wastewater passes through the high-efficiency The magnetic separation device, after pre-magnetization, forms magnetic seeds and magnetic flocs, then separates the nano-flocculation agent, and measures the turbidity and COD value of the effluent. The results showed that the removal rate of turbidity and COD reached above 95% and 80% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com