Low-alkali expansive moderate heat silicate cement and production method thereof

A Portland cement, micro-expansion technology, applied in the field of cement, can solve the problem of no stricter requirements for alkali content, and achieve the effect of improving performance, high strength and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the above-mentioned alkali micro-expansion medium-heat Portland cement is specifically:

[0029] Raw material ratio weight composition is: limestone 67-80%, sandstone 8-15%, dolomite 7-13%, aluminum ore waste rock 0.5-5%, copper slag 4-9%; It is required to grind in a raw material mill to make a fineness of 0.08mm, and the sieve residue is not more than 16.0%;

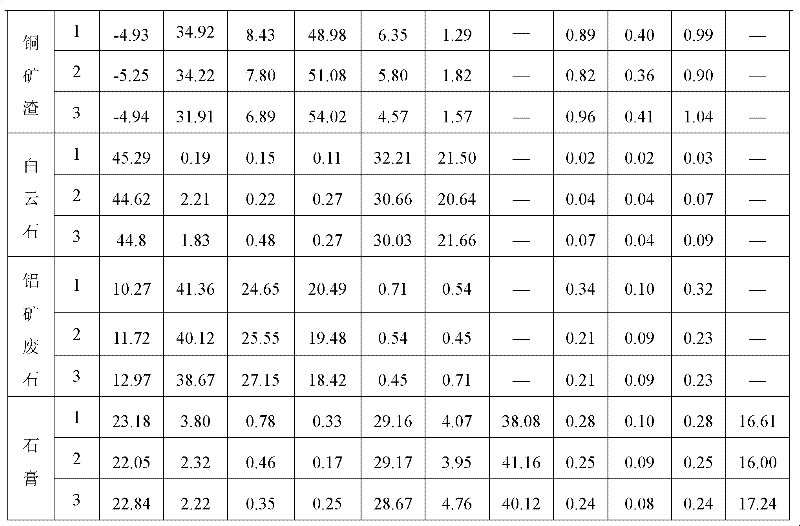

[0030] Send the above-mentioned raw materials into a new dry-process rotary kiln for coal-injection calcination, choose washed coal as fuel, the calorific value of washed coal (Qnet, ad) ≥ 5400cal / g, fuel coal ash alkali content ≤ 2.0%, total sulfur ≤ 2.0%;

[0031] The above-mentioned raw material is calcined by coal injection in a new dry method rotary kiln to obtain low-alkali and medium-heat Portland cement clinker, and the Al in the clinker 2 o 3 , Fe 2 o 3 , MgO, R 2 The content of O is controlled to be 3.5-4.5%, 5.0-6.0%, 3.0-5.0%, 0.25-0.50%, respectively, and f-CaO≤0.8%; ...

Embodiment

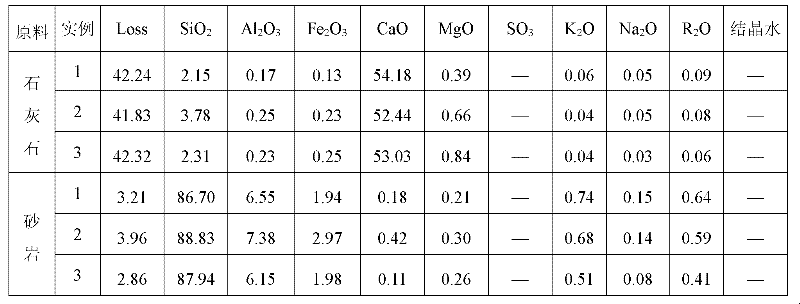

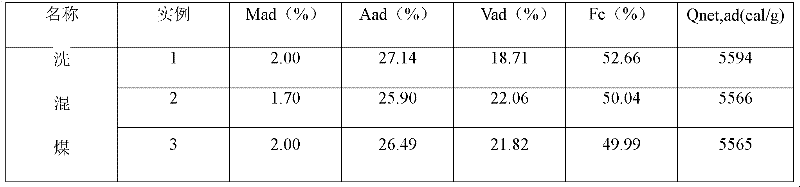

[0035] A certain proportion of limestone, high silica sandstone, copper slag, dolomite, aluminum ore waste rock, etc. are used as raw materials for batching. The main chemical components of the raw materials are shown in Table 1. The industrial analysis results and main chemical components of the fuel are shown in Table 2 and Table 2. Table 3. See Table 4 for the raw meal ingredient ratio. See Table 5 for the main chemical components and rate values of the raw meal. The medium-heat Portland cement clinker is calcined using a new dry process rotary kiln. The main chemical components of the clinker are shown in Table 6. The material rate and main mineral composition are shown in Table 7; the obtained clinker and gypsum powder are ground to obtain medium-heat Portland cement, and its main chemical composition control indicators and conventional physical properties are shown in Table 8 and Table 9, respectively. The fuel is washed coal. The washed coal processing plants in Leshan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com