Method for rapidly preparing LiAlON transparent ceramic powder

A technology for transparent ceramics and powders, applied in the field of preparing LiAlON transparent ceramic powders, can solve problems such as different synthesis processes, and achieve the effects of uniform particle size, high efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

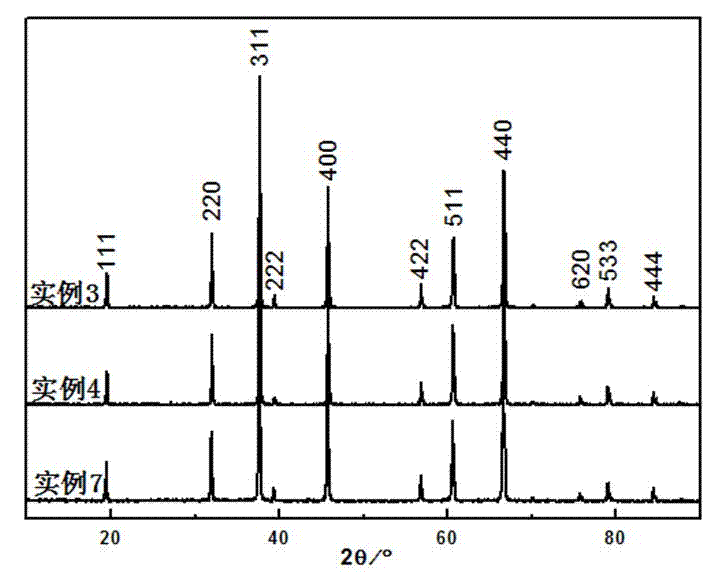

Embodiment 1

[0032] A kind of method for fast preparation LiAlON transparent ceramic powder, it comprises the steps:

[0033] 1) Weigh 87.25g of α-alumina powder, 3.04g of aluminum nitride powder and 9.71g of lithium oxide powder, and mix them in a mixing bottle to obtain a mixed powder; : 1 Add alumina balls, add 200mL absolute ethanol, and roll ball mill for 24 hours to obtain slurry;

[0034] 2) drying the slurry in step 1) (drying in vacuum at 50°C) to obtain a mixture;

[0035]3) Pass the dried mixture through a 100-mesh sieve, take 3g and put it into a graphite crucible coated with boron nitride on the inner wall. The crucible is placed in a graphite reactor, and the graphite reactor is placed in a high-current reaction synthesis device. 0.05Mpa nitrogen was introduced into the synthesis device as a protective gas; a large flow was directly applied to the graphite reactor, heated to 1700°C at a heating rate of 100°C / min, kept at this temperature for 10min, and then naturally lowered...

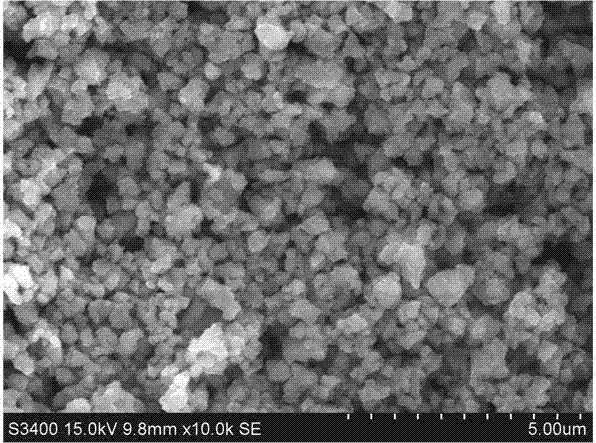

Embodiment 2

[0038] A kind of method for fast preparation LiAlON transparent ceramic powder, it comprises the steps:

[0039] 1) Weigh 93.51g of α-alumina powder, 5.99g of aluminum nitride powder and 0.5g of lithium oxide powder, and mix them in a mixing bottle to obtain a mixed powder; : 1 Add alumina balls, add 200mL absolute ethanol, and roll ball mill for 24 hours to obtain slurry;

[0040] 2) drying the slurry in step 1) (drying in vacuum at 50°C) to obtain a mixture;

[0041] 3) Pass the dried mixture through a 100-mesh sieve, take 3g and put it into a graphite crucible coated with boron nitride on the inner wall. The crucible is placed in a graphite reactor, and the graphite reactor is placed in a high-current reaction synthesis device. Introduce 0.02Mpa nitrogen into the synthesis device as a protective gas; directly apply a large flow to the graphite reactor, heat it up to 1650°C at a heating rate of 200°C / min, keep it at this temperature for 5min, and then cool it down to room t...

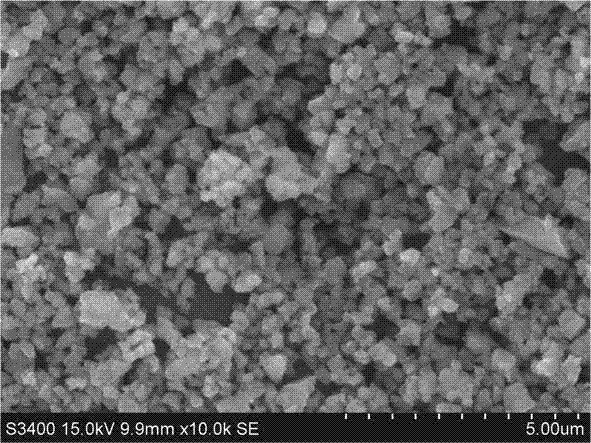

Embodiment 3

[0044] A kind of method for fast preparation LiAlON transparent ceramic powder, it comprises the steps:

[0045] 1) Weigh 75.12g of α-alumina powder, 14.92g of aluminum nitride powder and 9.96g of lithium carbonate powder, and mix them in a mixing bottle to obtain a mixed powder; : 1 Add alumina balls, add 250mL absolute ethanol, and roll ball mill for 24 hours to obtain slurry;

[0046] 2) drying the slurry in step 1) (drying in vacuum at 50°C) to obtain a mixture;

[0047] 3) Pass the dried mixture through a 100-mesh sieve, take 3g and put it into a graphite crucible coated with boron nitride on the inner wall. The crucible is placed in a graphite reactor, and the graphite reactor is placed in a high-current reaction synthesis device. 0.05Mpa nitrogen was introduced into the synthesis device as a protective gas; a large flow was directly applied to the graphite reactor, heated to 1600°C at a heating rate of 300°C / min, kept at this temperature for 2min, and then naturally co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com