Putty for repairing aerogenerator blade and preparation method therefore

A wind power generation blade and putty technology, applied in the direction of filling slurry, etc., can solve the problems of low impact resistance, low urethane bond energy, poor weather resistance, etc., and achieve good impact resistance, good adhesion, normal temperature and low temperature The effect of outstanding toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

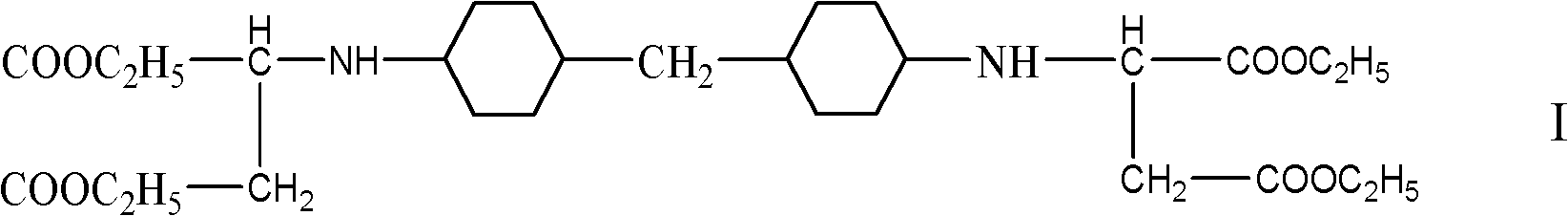

Method used

Image

Examples

Embodiment 1

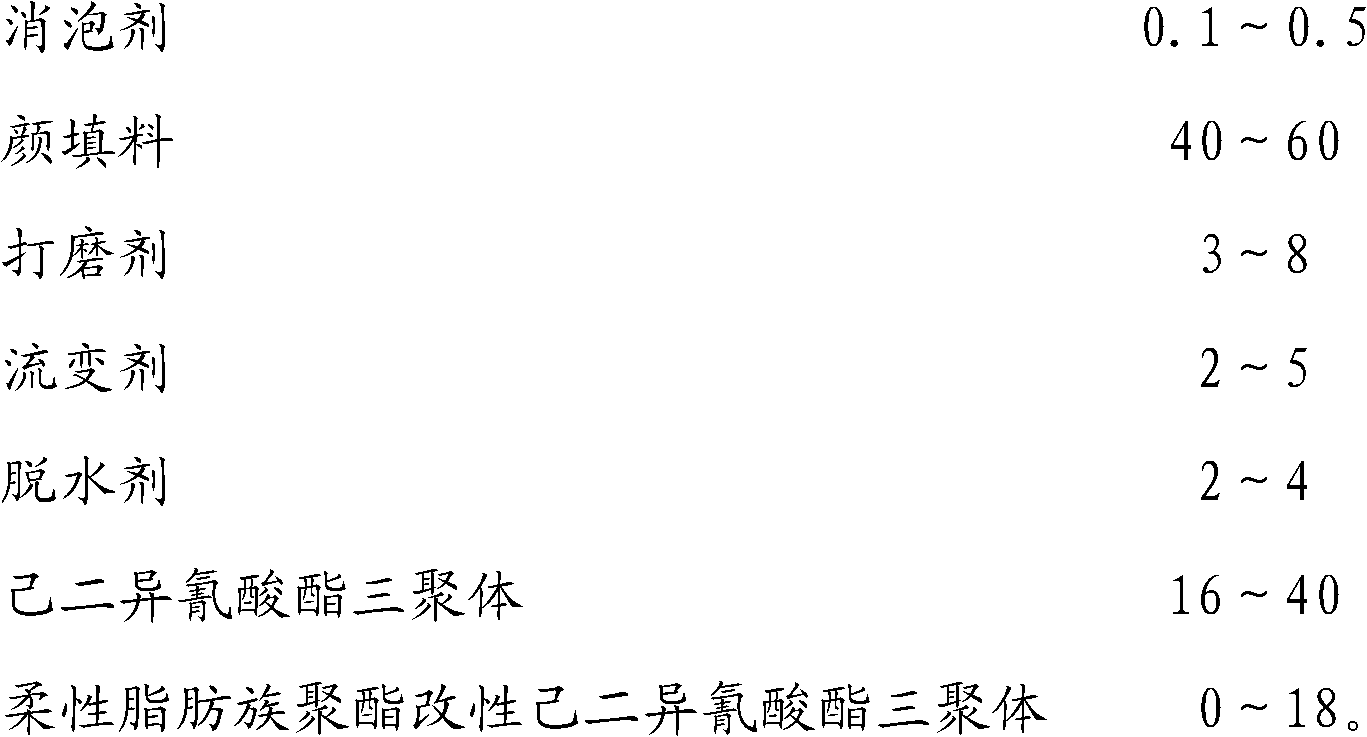

[0025] Embodiment 1 is used for wind power generation blade big flaw Large seam shaping putty for repair

[0026] Putty for wind power blade repair, where component A includes: polyaspartic acid ester resin 36kg, dispersant 0.5kg, defoamer 0.3kg, titanium dioxide 10kg, talcum powder 45kg, zinc stearate 5kg, gas phase Silica 1kg, organically modified bentonite 1kg, Activated molecular sieve powder 2kg; component B includes: hexamethylene diisocyanate (HDI) trimer 16.7kg, flexible aliphatic polyester modified HDI trimer 16.7kg;

[0027] Its preparation method is: ① polyaspartic acid ester resin, dispersant, defoamer, titanium dioxide, talcum powder, zinc stearate, fumed silica, organically modified bentonite, Put the activated molecular sieve powder into a vacuum high-viscosity mixer together and stir evenly (about 15 minutes), keep the vacuum at 0.02MPa during stirring, and wet for 12 hours after stirring evenly.

[0028] ② Pour the material obtained in step ① into a three...

Embodiment 2

[0031] Embodiment 2 is used for wind power generation blades eye of a needle Pinhole putty for defect repair

[0032] The preparation method is the same as in Example 1, and the contents of each component are shown in Table 1, and the various performance indexes of the prepared putty are shown in Table 2.

Embodiment 3

[0033] Embodiment 3 is used for wind power generation blade Low temperature resistant large seam patching putty

[0034] The preparation method is the same as in Example 1, and the contents of each component are shown in Table 1, and the various performance indexes of the prepared putty are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com