Method for quickly extracting carotenoid generated by in-vitro enzyme reaction

A carotene and extraction method technology, applied in the field of bioengineering, can solve the problems of low extraction amount, long time consumption, etc., and achieve the effects of increasing product extraction amount, reducing product loss, and shortening operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

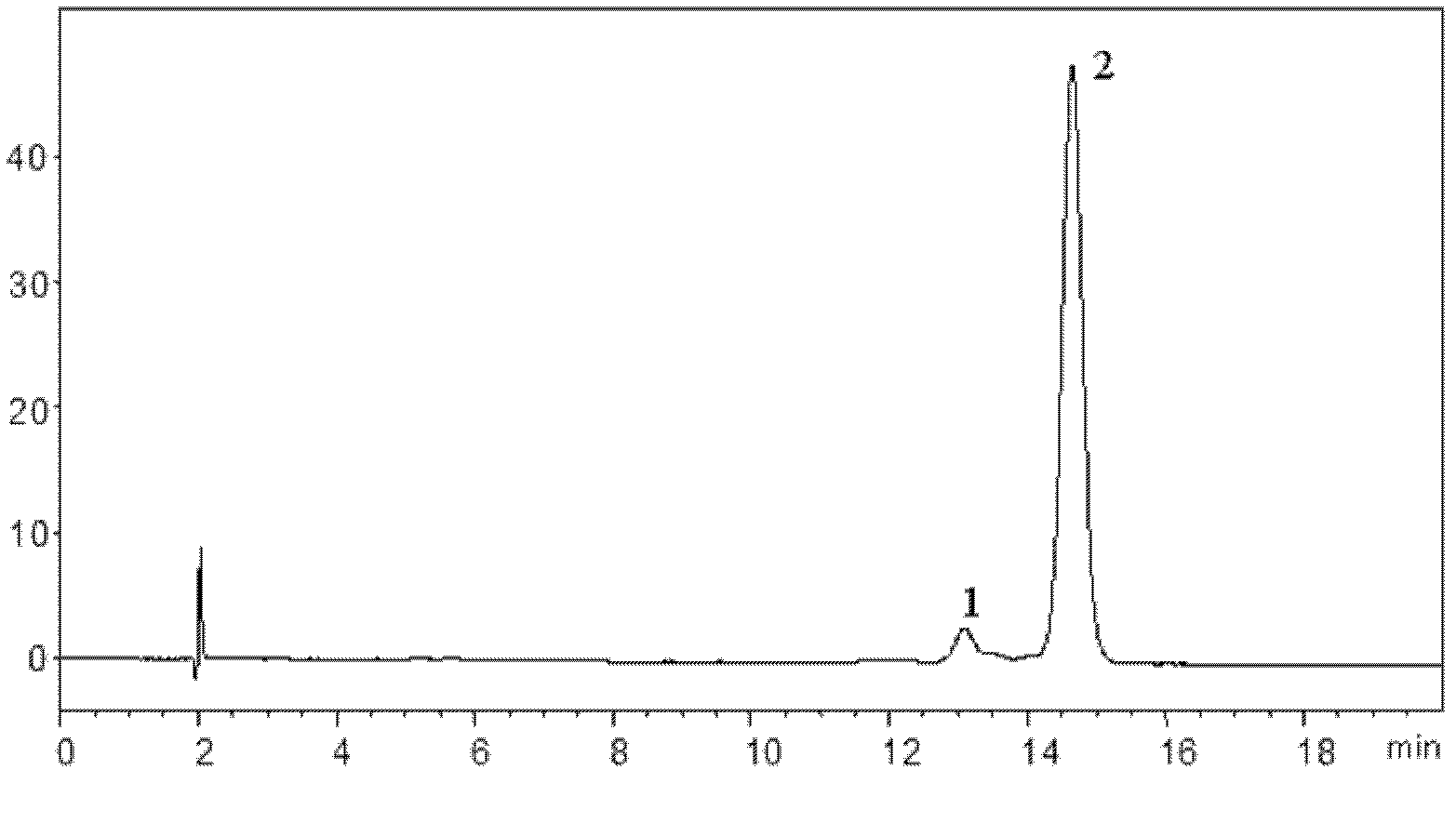

[0034] Example 1: Extraction of in vitro reaction product of Rhodobacter sphearoides No.ATCC 17025 recombinant phytoene dehydrogenase

[0035] A rapid extraction method for generating carotenoids by enzymatic reaction in vitro, the steps are as follows:

[0036] (1) Take 200 mL of E. coli culture fluid expressing Rhodobacter sphaeroides recombinant phytoene dehydrogenase, centrifuge at 12,000 rpm for 5 minutes, and collect bacterial cells; resuspend the collected E. coli cells in 10 mL of 100 mmol / L Tris. In the HCl (pH7.9) buffer solution, the ultrasonic breaker of Sonics Company of the United States was crushed for 30 minutes (22kHz, 150W) to obtain the crude enzyme liquid of phytoene dehydrogenase;

[0037] (2) Take 400 μL of the crude phytoene dehydrogenase enzyme solution prepared in step (1) in a 1.5 mL centrifuge tube, add phytoene acetone solution, glucose, glucose oxidase and catalase, The final concentrations were 10μmol / L (phytoene), 2mmol / L (glucose), 20U / mL (gluc...

Embodiment 2

[0043] Example 2: Extraction of in vitro reaction product of Rhodobacter sphearoides No.ATCC 17025 recombinant hydroxystreptosporin synthase

[0044] Get 200 mL of E. coli culture fluid expressing rhodobacter sphaeroides recombinant hydroxystreptosporin synthase and centrifuge at 12000 rpm for 5 minutes to collect the bacterial cells; the bacterial cells are resuspended and broken as in Example 1, and 400 μL of broken liquid is added to the streptosporin acetone solution , so that the final concentration of streptosporin was 10 μmol / L, and the reaction system was adjusted to 500 μL with buffer. All the other operations and steps are the same as in Example 1.

[0045] The in vitro reaction product of the above-mentioned Rhodobacter sphaeroides recombinant hydroxystreptosporin synthase is hydroxystreptosporine, and the extraction amount is 1.748 μg.

experiment example

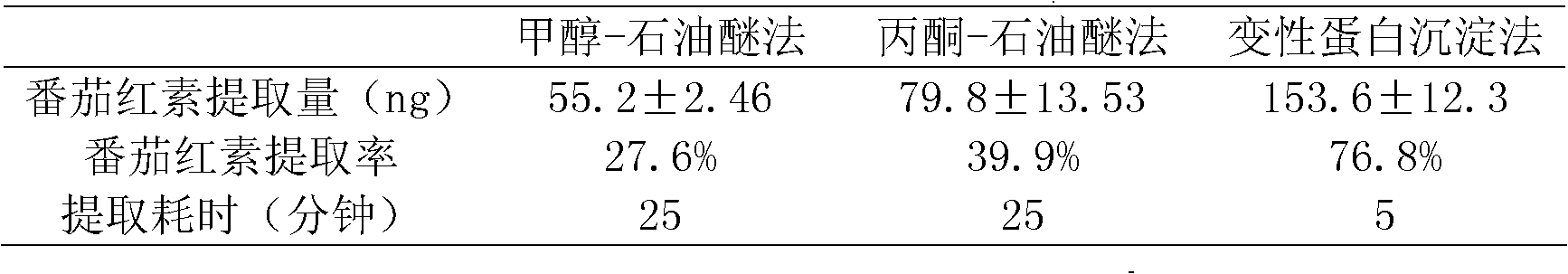

[0046] Experimental example: comparison of lycopene extraction methods in in vitro enzyme reaction system

[0047] Take 4 mL of the cell disruption solution described in Example 1, add 100 μL of 20 μg / mL lycopene in acetone solution, dilute to 5 mL with buffer, and divide into 9 parts at 500 μL / part after mixing, 3 parts are 1 group, a total of 3 Group; using methanol-petroleum ether extraction, acetone-petroleum ether extraction and denatured protein precipitation extraction method described in Example 1 for product extraction.

[0048] (1) Methanol-petroleum ether: Add 2.5 mL of methanol to 500 μL of the mixture and incubate at 55°C for 15 minutes, add 300 μL of petroleum ether (boiling range 30°C to 60°C) and shake for 5 minutes to extract lycopene, and centrifuge to collect the upper layer of petroleum ether.

[0049] (2) Acetone-petroleum ether: Add 2.5 mL of acetone to 500 μL of the mixture and incubate at 55°C for 15 minutes, add 300 μL of petroleum ether (boiling range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com