Surface modification method of aliphatic polyester electrospun fiber by using sodium alginate and gelatin

A technology of aliphatic polyester and sodium alginate, applied in fiber processing, textile and papermaking, medical science, etc., can solve the problems of easy interface peeling, reduce mechanical properties, etc., and achieve the effect of wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples illustrate the present invention further.

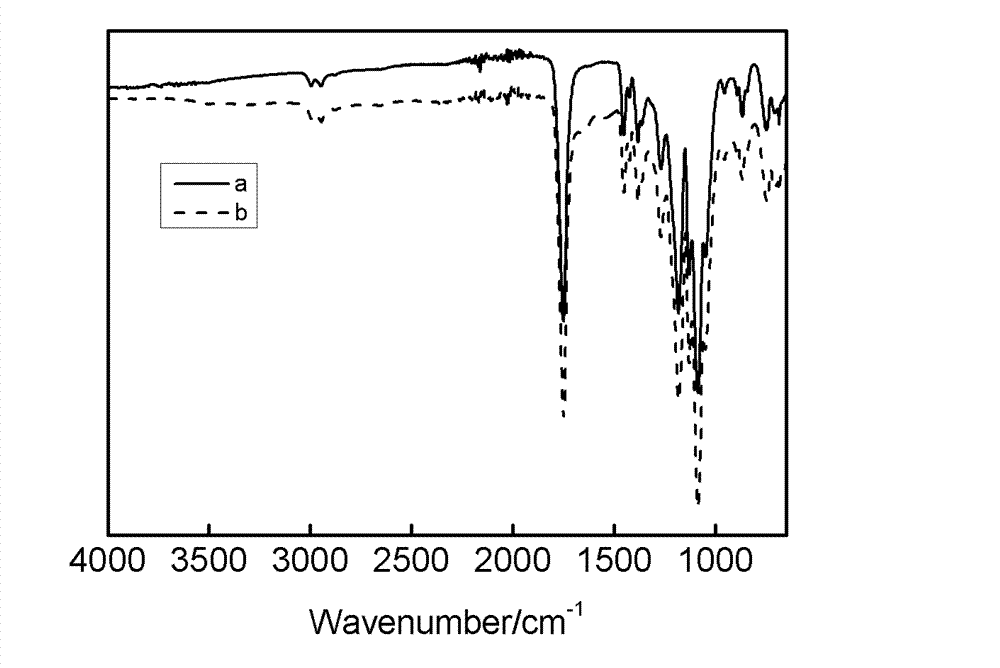

[0030] PLGA was dissolved in hexafluoroisopropanol to obtain a concentration of 10% w / v spinning solution. Under the conditions of voltage 8kV, solution flow rate 0.5mL / h, and receiving distance 10cm, the electrospun PLGA fiber membrane was obtained by using a grounded metal plate, and dried in vacuum for 24h. Cut the fiber membrane to an appropriate size, immerse it in a diluted solvent of 10% v / v trifluoroethanol aqueous solution for 20 minutes, take it out and absorb the surface liquid, then immerse the fiber membrane in a 5mg / mL sodium alginate aqueous solution for 24 hours, take it out, rinse it with distilled water Absorb the surface moisture, soak the dried fiber membrane in 10mg / M1EDC / NHS (1:1) cross-linking agent aqueous solution at 4°C for 2h, take out the distilled water and rinse, soak the rinsed fiber membrane at 4°C at 10mg / mL In the gelatin solution, take it out after 24 hours, rinse with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com