A kind of preparation method of highly elastic tin phosphor bronze alloy foil

A technology of tin phosphor bronze and alloy foil, which is applied in the production field of C5210 alloy foil, can solve the problems of unstable electrical conductivity, insufficient normal force, and many punching burrs, so as to reduce the number of annealing times, improve the structure and properties, and improve the elasticity. The effect of modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

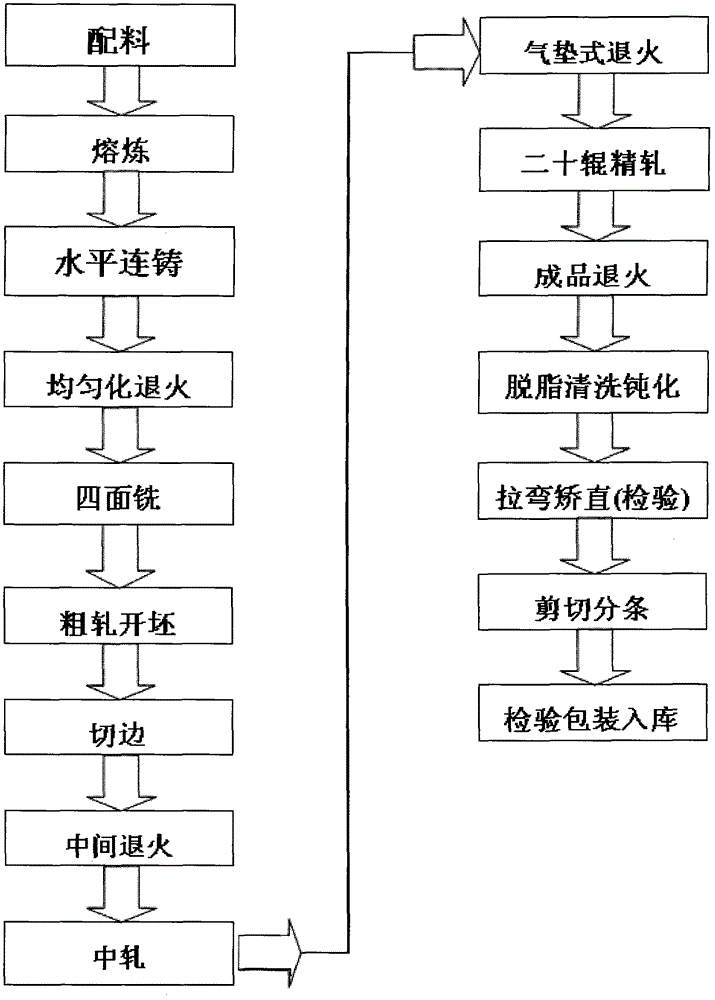

Method used

Image

Examples

Embodiment 1

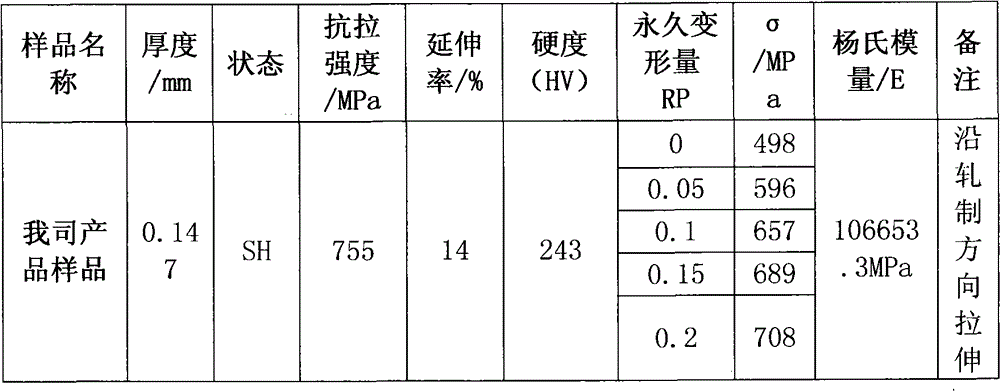

[0024] To produce foils with C5210 SH specification of 0.15×400mm, melt the prepared materials in the melting furnace, control the temperature of the molten copper in the melting furnace at 1240±10°C, control the P content of the chemical composition at 0.22%, and control the Ni content at 0.01% , the Sn / P ratio is 35, and the balance is copper. Transfer the qualified copper liquid into the holding furnace, and the casting temperature is 1190±10°C. The horizontal continuous casting adopts the pull-stop-reverse process, the casting speed is controlled at 165mm / min, and the billet outlet temperature is 300-360°C. The thickness of the slab is controlled at 16mm, the width is 430mm, and the length is 100m.

[0025] Homogenize the produced slab, anneal at 680°C, and hold for 12 hours. After annealing, the slab is face milled. The upper and lower face milling amounts are 0.75 / 0.85mm respectively, and the total side milling amount is 2mm. Roll the milled blank to 2.5mm, transfer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com