Ammonium Chloride Rare Earth Wastewater Treatment and Recycling Process

A technology for wastewater treatment and ammonium chloride, applied in metallurgical wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of shortening reverse osmosis membrane water treatment efficiency, high pump requirements, and multiple energy sources. Achieve the effect of improving efficiency and working range, reducing energy consumption and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail with reference to specific embodiments below through the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

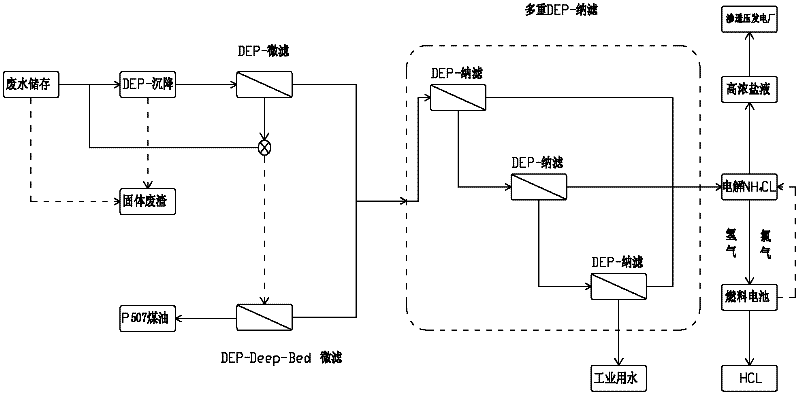

[0014] A kind of ammonium chloride rare earth wastewater treatment recycling process, concrete steps and working conditions are as follows:

[0015] (1) The suspension after the sedimentation treatment is input into the DEP microfiltration, and the working pressure is 1 to 2 bar to remove the solid particles contained in the suspension, and the concentrated solution is recycled to the sedimentation again. The liquid of solid suspension is input into the DEP nanofiltration group;

[0016] (2) After multiple cycles, the concentrated kerosene emulsion containing solid particles will be input to the DEP-DEEP-BED microfiltration process to separate the kerosene emulsion from the suspension. The working princip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com