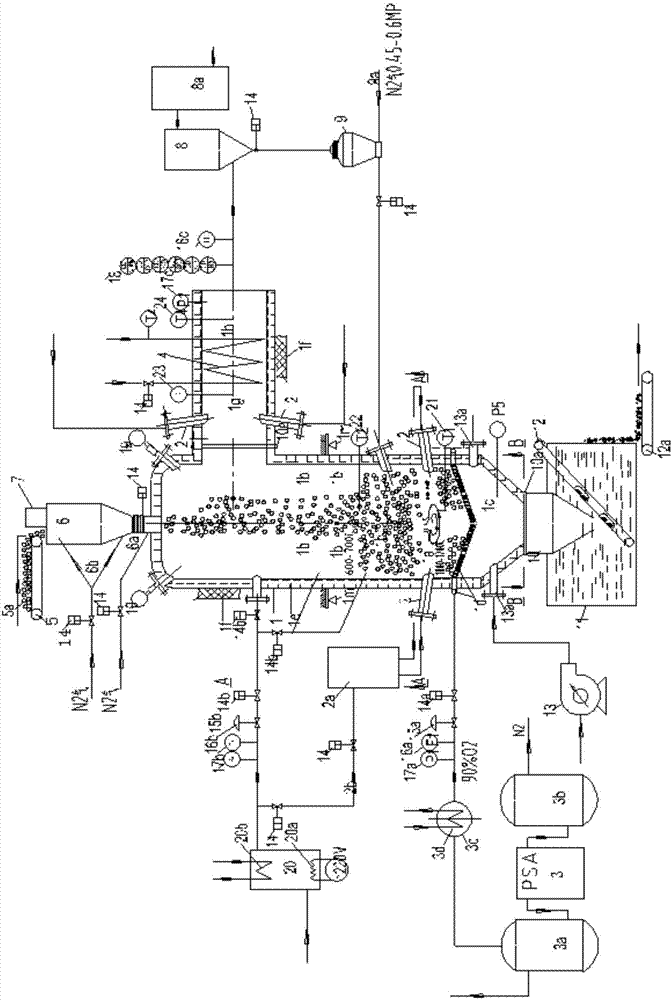

Device for preparing combustible gas by virtue of plasma pyrolysis and oxygen-enriched combustion-supporting material

An oxygen-enriched combustion-supporting and plasma technology, applied in the manufacture of combustible gas, granular/powdered fuel gasification, petroleum industry, etc., can solve the problems of air pollution, complex complete equipment, low thermal efficiency, etc., and achieve the effect of improving gas production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: An embodiment of using the device to gasify biomass materials;

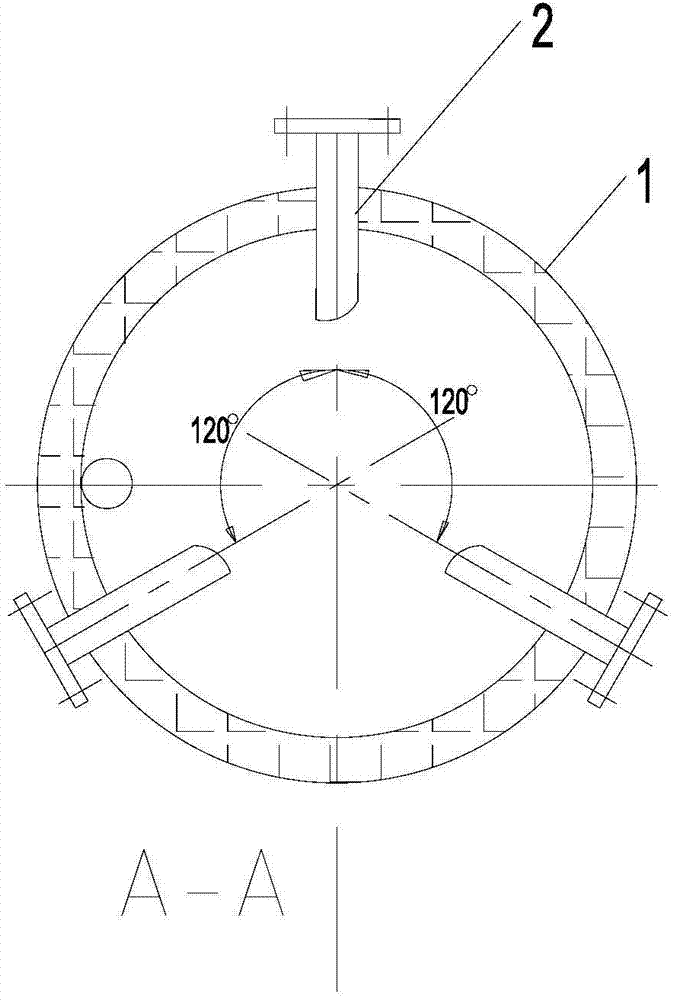

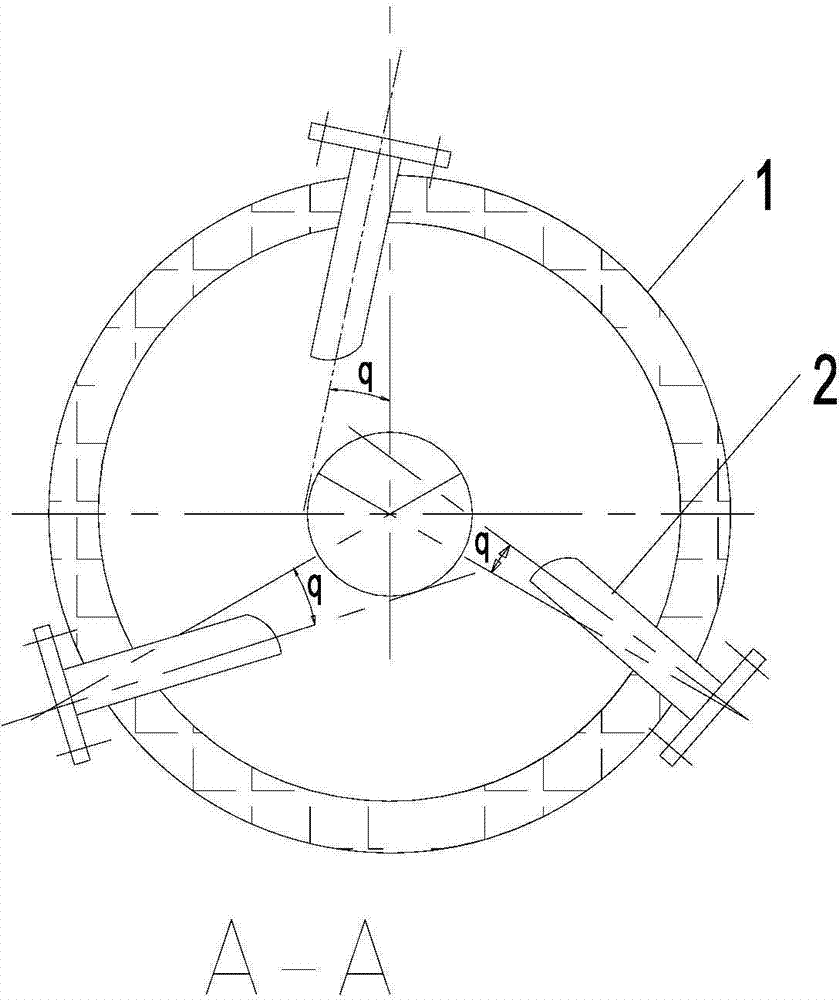

[0058] Pyrolysis zone 1a plasma generator press Figure 5 Configuration, when the plasma generator is working, it can also be configured according to the needs Figure 6 ,or image 3 ,or Figure 5 work, the plasma generator in the second pyrolysis zone presses Figure 6 configuration.

[0059] Start the PSA adsorption oxygen generator 3 to prepare enough rich oxygen and N 2 Gas spare.

[0060] Start the electric heater of steam generator 20, prepare steam for standby.

[0061] Start the bag filter 7, start the material belt metering machine, the biomass material 5a (the particle size is not more than 50mm, the smaller the particle size, the better the gasification effect) is fed into the gasifier through the hopper door of the feeding hopper 6, and reaches the furnace In the pyrolysis zone 1a, start the plasma generator in the pyrolysis zone to pyrolyze and gasify the biomass. Under a...

Embodiment 2

[0065] Embodiment 2: An embodiment of using this device to gasify waste polymer compounds (commonly known as plastic waste);

[0066] Pyrolysis zone 1a plasma generator press Figure 5 Configuration, when the plasma generator is working, it can also be configured according to the needs Figure 6 ,or image 3 ,or Figure 5 work, the plasma generator in the second pyrolysis zone presses image 3or Figure 6 configuration.

[0067] Start the PSA adsorption oxygen generator 3 to prepare enough rich oxygen and N 2 Gas spare.

[0068] Start the electric heater of steam generator 20, prepare steam for standby.

[0069] As we all know, the main components of plastic waste are hydrocarbon polymers. Polyphenylene and polychloride also contain Cl elements. In plastic products, there are color masterbatches and surface printing colors, most of which are metal compounds such as iron, chromium, cobalt, Compounds of copper and nickel, in order to remove these elements, 5%-15% by weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com