A kind of treatment method of waste copper sulfate electrolyte

A treatment method, copper sulfate technology, applied in the field of impurities, can solve the problems of rising operating costs, small electrolyte circulation, complex operation, etc., achieve the effect of safe and environmentally friendly working environment, enhance market competitiveness, and shorten the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

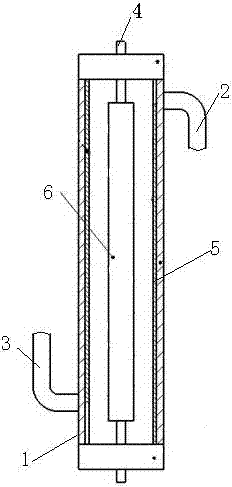

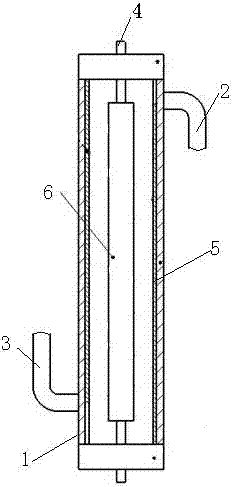

Image

Examples

Embodiment

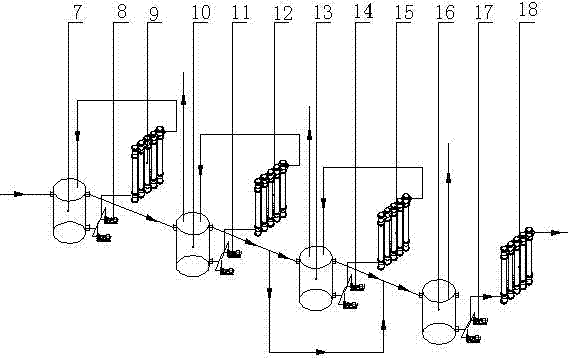

[0026] A treatment method for waste copper sulfate electrolyte, the waste copper sulfate electrolyte from the electrolysis system is in the electrolytic cell of the first electrowinning module block and the second electrowinning module group under the action of 1# and 2# delivery pumps , The electrolyte is decoppered under the action of high current density and high circulation flow in the cylinder to produce standard cathode copper. After the concentration of copper ions in the liquid after decoppering of the second electrowinning module meets the technical requirements, the flow is shunted, and the liquid after all the way of decoppering flows directly into the third electrowinning module group, and the deep decopper is carried out at a higher current density and a higher circulation flow rate. Copper, the concentration of copper ions in the liquid after decoppering of the third electrowinning module group meets the technical requirements, and then enters into the fourth elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com