Gradually degradable woven ureter scaffold tube and preparation method thereof

A technology for ureteral stents and degradation speed, applied in the field of braided ureteral stents and its preparation, and textile biomedical materials, can solve problems such as blockage, single degradable materials, large stent fragments, etc., achieve high economic benefits, and simple preparation process , the effect of good identity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

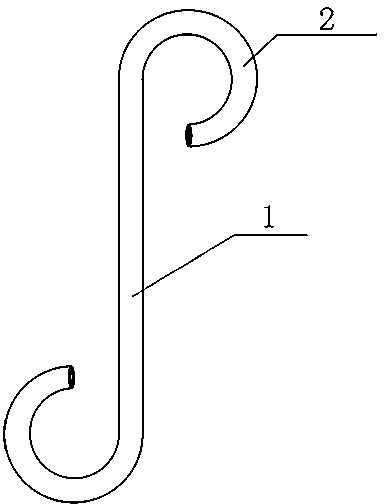

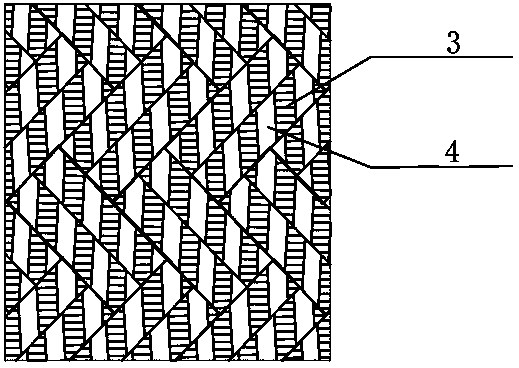

Embodiment 1

[0040]First, PGA (30dtex / 8f) multifilament fiber and PGLA (30dtex / 8f) multifilament fiber are braided into twisted yarns on the braiding machine, one of which is made of a PGA (30dtex / 8f) multifilament fiber and a Root PGLA (30dtex / 8f) multifilament fiber composition, such as figure 2 As shown, it is a schematic diagram of a diamond-shaped braiding structure. The twisted yarns are respectively poured onto the spindles of a 16-spindle braiding machine. The take-up ratio of the braiding machine is 5, and the yarn is braided on the first core with a diameter of 0.6mm by using a diamond-shaped braiding method. On the mould, the length of the braided tube is 16.0cm; shape it in a vacuum oven at 110°C for 10 minutes, and then remove the braided layer from the first mandrel to form a stent tube; The inner diameter of the tube and the second mandrel with a length of 3.0cm are wrapped around a polytetrafluoroethylene solid rod with a diameter of 1.0cm to form a single ring, and then s...

Embodiment 2

[0043] First, weave PGA (60dtex / 16f) and PGLA (60dtex / 16f) multifilament fibers into two kinds of yarns on the braiding machine, one of which is composed of two PGA multifilament fibers, and the other is composed of two PGLA multifilament fibers Composition, the two kinds of yarns are distributed according to the rule of 1 every 1 and poured on the spindles of the 24-spindle braiding machine. The take-up ratio of the braiding machine is 6, and the yarn is braided on the first core with a diameter of 3.0mm by using a diamond braiding method. On the mould, the length of the braided tube is 59.0cm; shape the braided layer from the first mandrel in a vacuum oven at 145°C for 6.5 minutes to form a stent tube; insert a diameter smaller than the stent tube at both ends of the preliminarily shaped stent tube The second mandrel with an inner diameter and a length of 15.7cm is wrapped twice around a solid polytetrafluoroethylene rod with a diameter of 2.5cm to form two rings, and then sh...

Embodiment 3

[0046] First, PGA (100dtex / 24f) and PGLA (100dtex / 24f) multifilament fibers are woven into a yarn on a braiding machine, wherein each yarn is composed of two PGA multifilament fibers and one PGLA multifilament fiber, which are poured separately On the spindle of the 32-spindle braiding machine, the take-up ratio of the braiding machine is 7, the yarn is braided on the first mandrel with a diameter of 5.8mm by using a diamond braiding method, and the length of the braiding tube is 74.2cm; in a vacuum oven at 180°C In 3.0 minutes of setting, the braided layer is removed from the first mandrel to form a stent tube; the two ends of the initially shaped stent tube are respectively inserted into a second mandrel with a diameter smaller than the inner diameter of the stent tube and a length of 14.6 cm. A 4.0cm polytetrafluoroethylene solid rod is formed into a pigtail shape, and then shaped in a vacuum oven at 180°C for 3.0min, then it is withdrawn from the polytetrafluoroethylene sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com