A kind of preparation method of cellulose-based toxic gas adsorption material

An adsorption material and toxic gas technology, which is applied in the field of preparation of cellulose-based toxic gas adsorption materials, can solve the problems of high raw material cost, less research on ion exchange fibers, and difficult degradation, etc., and achieve fast adsorption speed, good chemical stability, The effect of easy desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

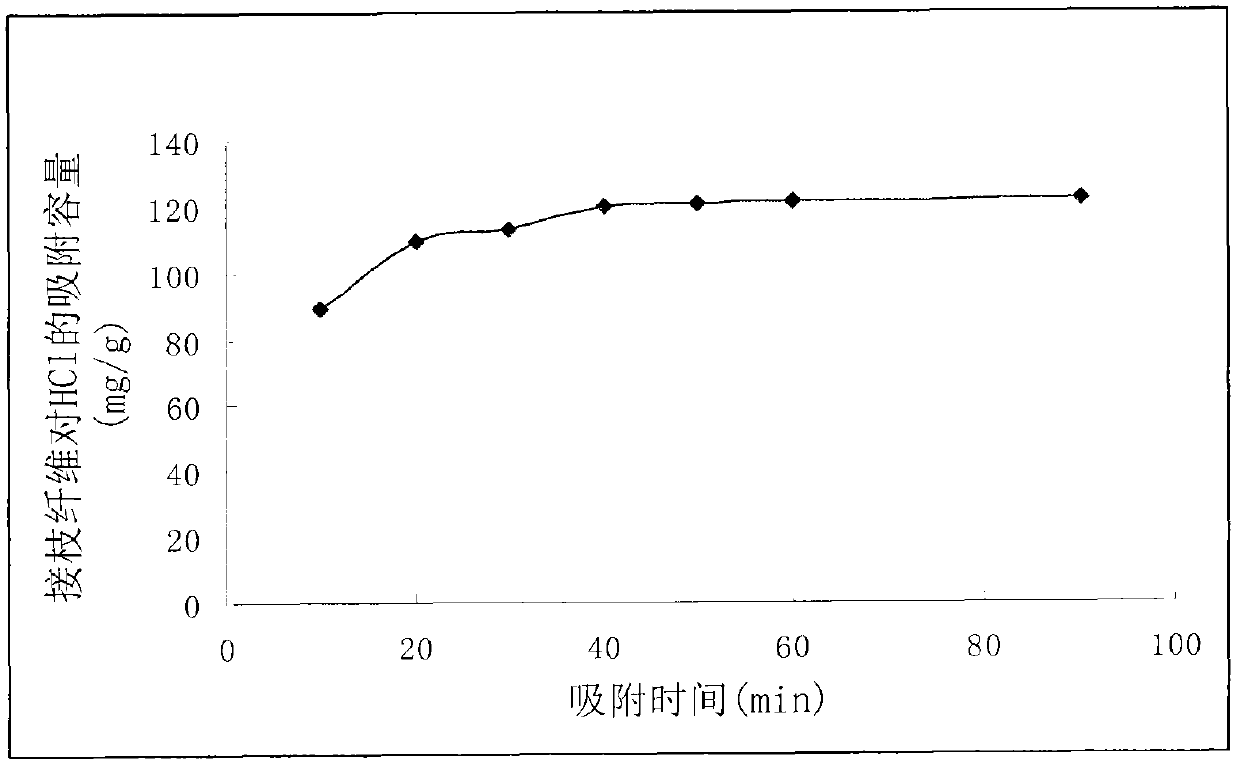

Embodiment 1

[0052] Weigh 100g of bagasse cellulose, after being decomposed by a decomposer for 5min, wash with distilled water at a temperature of 25°C, then wash with ethanol with a three-fold volume concentration of 95%, filter and dry, and then soak in 8% NaOH solution for 30h for activation After treatment, filter with suction, wash until the pH value is 7, and dry; add 200 g of water according to the mass ratio of bagasse cellulose to water of 0.5:1, and microwave gelatinization at a power of 300W for 5 minutes; take out the gelatinized product and press bagasse Add 20g of ammonium cerium nitrate initiator at a mass ratio of cellulose to initiator of 5:1, and initiate for 2min at a microwave power of 500W; Ethylenetriamine, mixed evenly, reacted under 100W microwave for 15min, washed with distilled water and dried at 60°C for 10h to obtain 135g of toxic gas adsorption material.

[0053] The applicant measured the zeta potential of the above-mentioned toxic gas adsorption material, an...

Embodiment 2

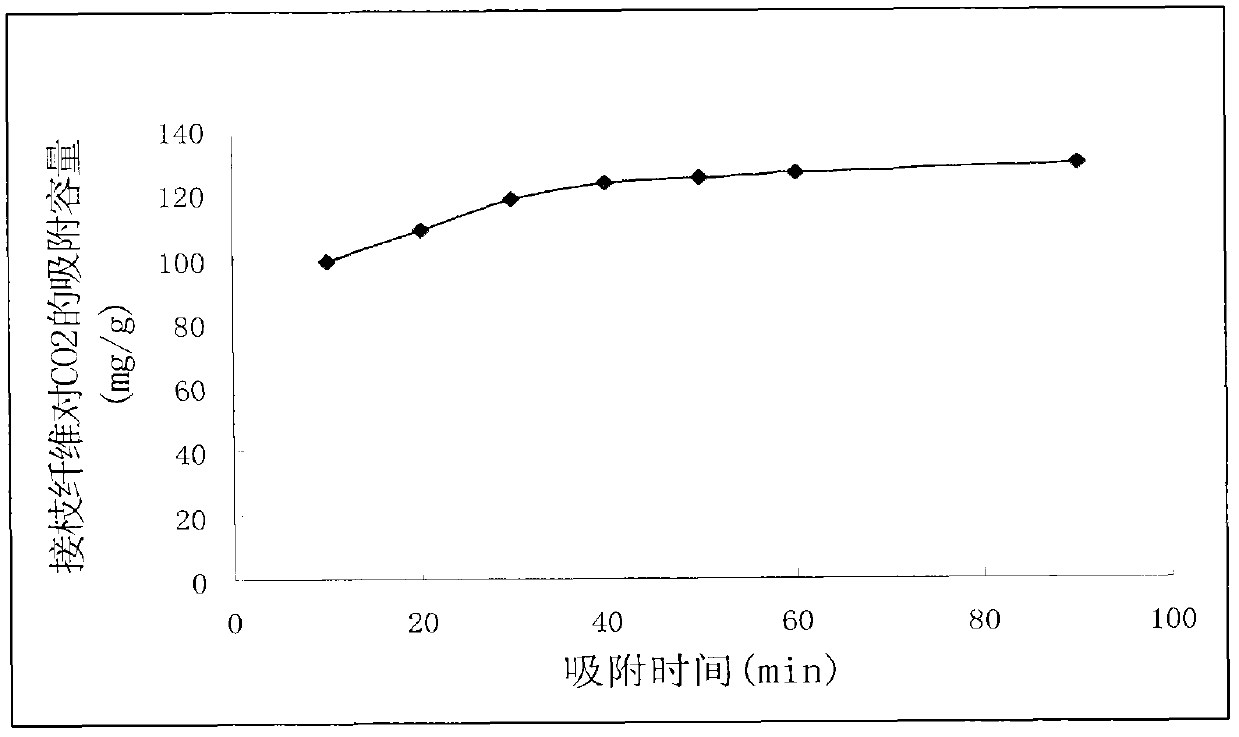

[0061] Weigh 100g of moso bamboo fiber, after being decomposed by a decomposer for 8min, wash with distilled water at a temperature of 25°C, then wash with 95% ethanol with a triple volume concentration, filter and dry, and then soak in 15% NaOH solution for 15h for activation treatment Finally, filter with suction, wash until the pH value is 7, and dry; add 25 g of water to moisten according to the mass ratio of moso bamboo cellulose to water of 4:1, and microwave gelatinization at a power of 100W for 3 minutes. Take out the gelatinized product and add 10 g of water-soluble V-50 initiator or water-soluble hydrogen peroxide-ferrous salt according to the mass ratio of bamboo cellulose and initiator of 10:1, and initiate at 300W microwave power for 3 minutes. Then add 200g of tetraethylenepentamine according to the mass ratio of monomer to bamboo cellulose in the ratio of 1:0.5, mix evenly, react at 350W microwave power for 10min, wash with distilled water and dry at 60°C for 10h...

Embodiment 3

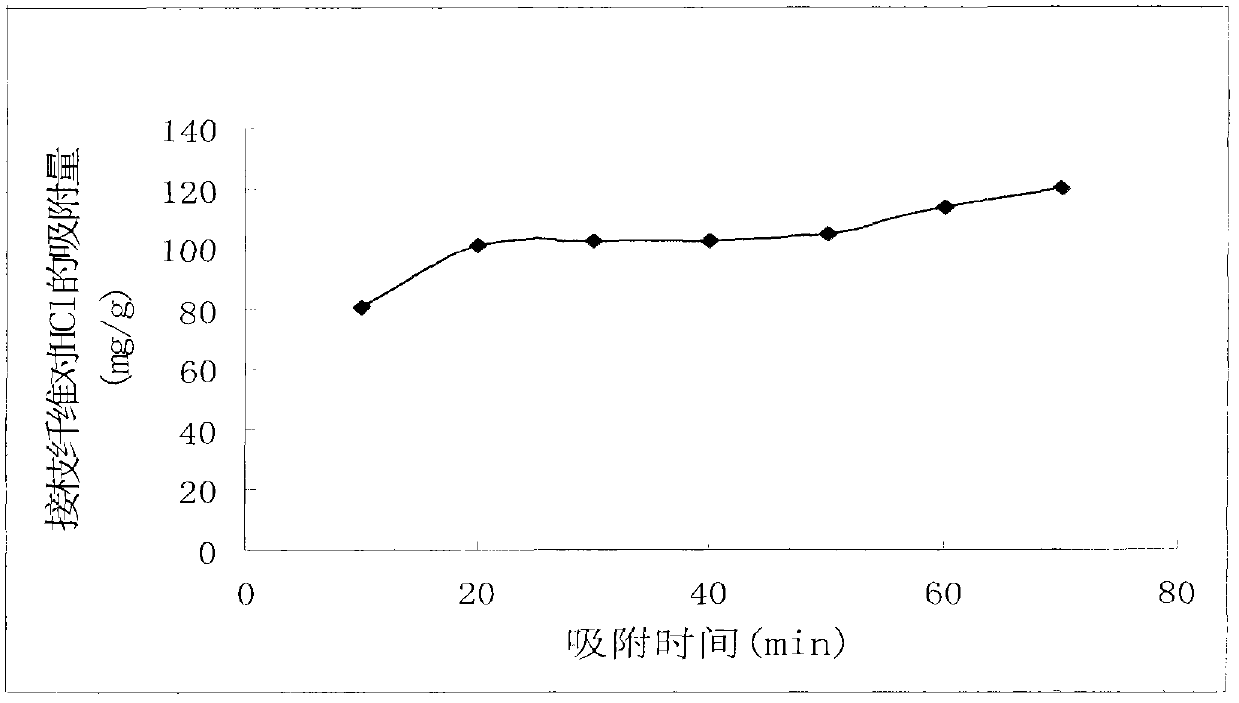

[0066] Weigh 100g of cassava stalk fibers, and after being decomposed by a decomposer for 3 minutes, wash with distilled water at a temperature of 25°C, then wash with ethanol with a three-fold volume concentration of 95%, filter and dry, and then soak in 30% NaOH solution for 10 hours to activate After treatment, filter with suction, wash until the pH value is 7, and dry; then add 50 g of water to moisten according to the mass ratio of cassava stalks and water at a ratio of 2:1, and microwave gelatinization at a power of 500W for 2 minutes. Take out the gelatinized product and add 25g potassium persulfate initiator in the ratio of 4:1 by the mass ratio of cassava stalk fiber and initiator, initiate 5min under 100W microwave power, then be 1:4 by the mass ratio of monomer and cassava stalk Add 25g of triethylenetetramine, mix well, react under 500W microwave for 3min, wash with distilled water, and dry at 60°C for 10h to obtain 129g of toxic gas adsorption material.

[0067] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com