Bowl-shaped particle or dumbbell-shaped hollow particle of titanium dioxide and preparation method thereof

A titanium dioxide, dumbbell-shaped technology, applied in the directions of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve problems such as inability to prepare individual bowl-shaped particles, inability to adapt to industrial production, and easy occurrence of voids at the bottom of the bowl, without the need for Precision equipment, smooth bowl edges, mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

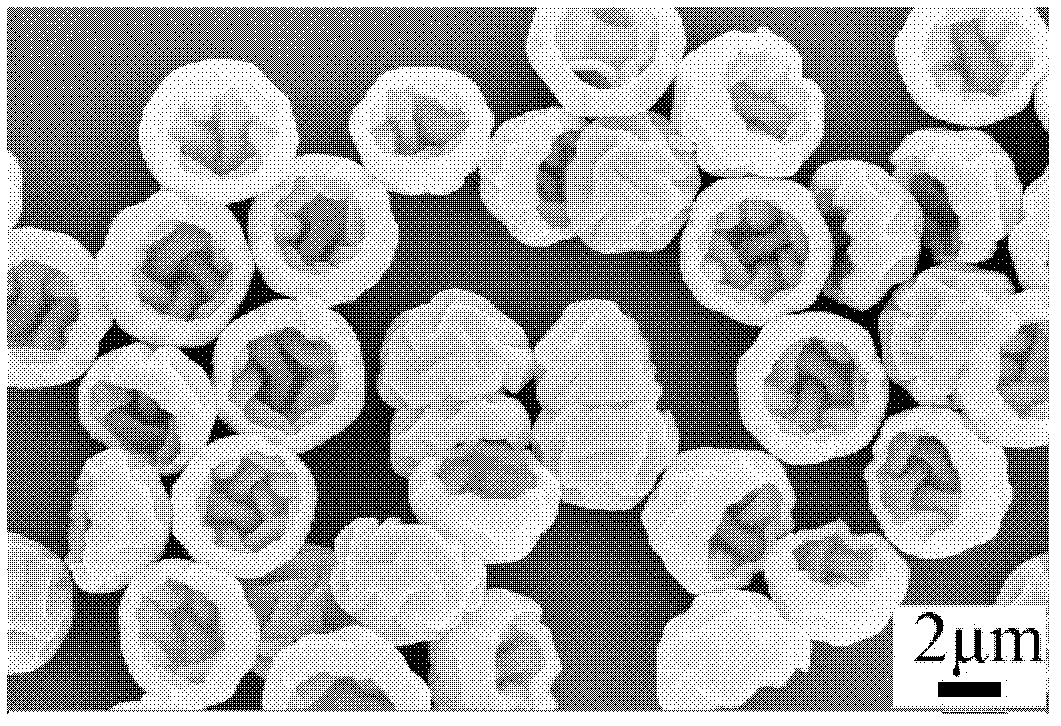

[0020] Weigh 1 g of dumbbell-shaped PS microspheres and disperse them into 120 g of concentrated sulfuric acid, and modify them at a constant temperature of 24 hours at 30 °C to form a hydrophilic layer on the surface of PS. The long diameter of the dumbbell-shaped PS microspheres is 7.2 μm and the short diameter is 5 μm. Disperse the modified dumbbell-shaped PS into isopropanol solution of butyl titanate (60% concentration by mass), and stir at 30°C for 24 hours to make the modified dumbbell-shaped PS fully adsorb butyl titanate. Then centrifuge, then disperse into water, react for 8h and centrifuge to get PS / TiO 2 Core-shell particles. Finally put the PS / TiO 2 Core-shell particles are sintered at a sintering temperature of 450°C, and the heating rate is 100°C / min to obtain anatase TiO 2 Bowl-shaped particles. Such as figure 1 As shown, the diameter of the mouth of the bowl-shaped structure is 3.35 μm, the diameter of the bowl body is 5.02 μm, the height is 3.6 μm, the th...

Embodiment example 2

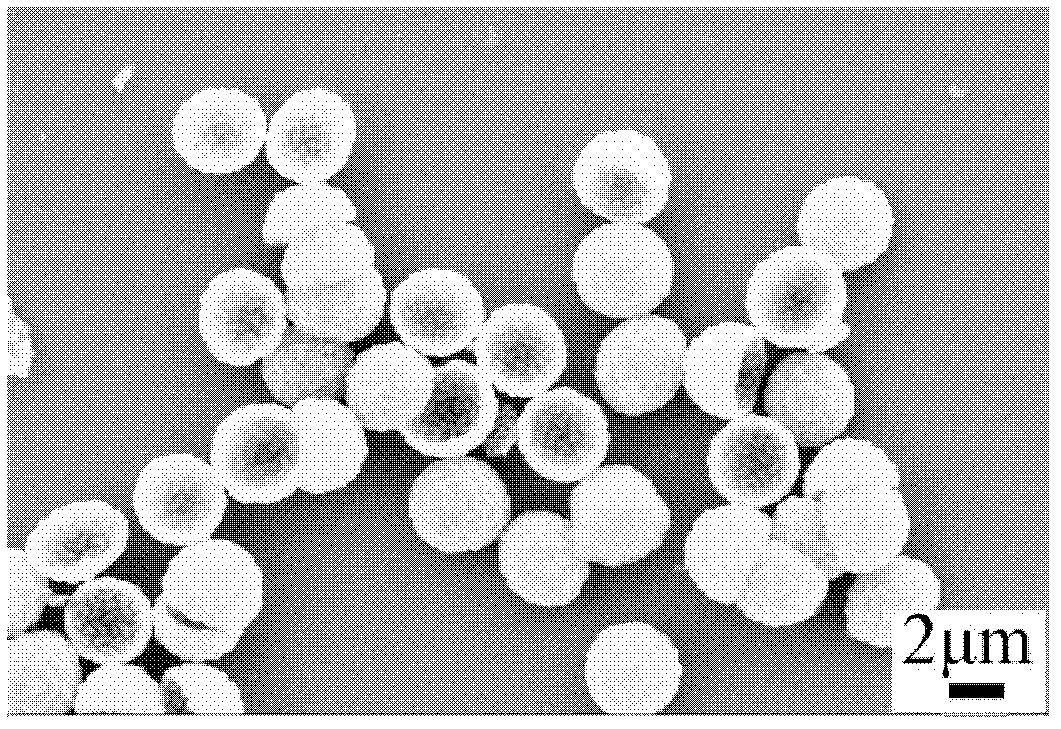

[0022] Weigh 1g of dumbbell-shaped PS microspheres and disperse them into 10g of concentrated sulfuric acid, and modify them at a constant temperature of 80°C for 2h to form a hydrophilic layer on the surface of PS. The long diameter of the dumbbell-shaped PS microspheres is 5.4 μm and the short diameter is 3.5 μm. Disperse the modified dumbbell-shaped PS into an ethanol solution of isobutyl titanate (50% by weight concentration), and stir at 20°C for 24 hours to make the modified dumbbell-shaped PS adsorb isobutyl titanate. Then centrifuge, disperse into water, react for 8h and then centrifuge to get PS / TiO 2 Core-shell particles. Finally put the PS / TiO 2 Core-shell particles are sintered at a sintering temperature of 430°C and a heating rate of 120°C / min to obtain anatase TiO 2 Bowl-shaped particles. Such as figure 2 As shown, the diameter of the mouth of the bowl-shaped structure is 3.15 μm, the diameter of the bowl body is 3.44 μm, the height is 2.68 μm, the thickness...

Embodiment example 3

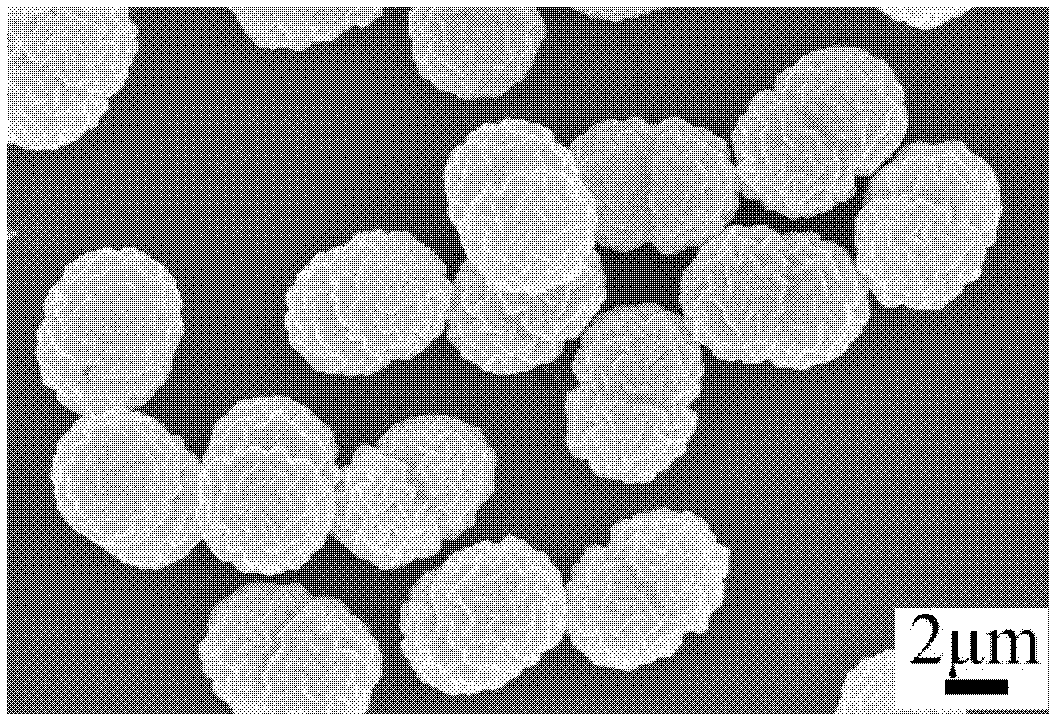

[0024] Weigh 1g of dumbbell-shaped PS microspheres and disperse them into 800g of concentrated sulfuric acid, and modify them at a constant temperature of 50°C for 16 hours to form a hydrophilic layer on the surface of PS. The long diameter of the dumbbell-shaped PS microspheres is 5.4 μm and the short diameter is 4 μm. Disperse the modified dumbbell-shaped PS into an ethylene glycol solution of isopropyl titanate (concentration: 70% by mass), and stir at 50°C for 12 hours to make the modified dumbbell-shaped PS adsorb isopropyl titanate. Then centrifuge and disperse into water, centrifuge and wash after 36h to obtain PS / TiO 2 Core-shell particles. Finally put the PS / TiO 2 Core-shell particles are sintered at a sintering temperature of 350°C, and the heating rate is 5°C / min to obtain anatase TiO 2 Bowl-shaped particles. Such as image 3As shown, the dumbbell-shaped particles are connected by two spherical caps, the long diameter is 5.65 μm, the short diameter is 4.2 μm, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com