Precise aeration and combined defoaming process scheme for landfill leachate treatment

A technology of landfill leachate and process scheme, applied in the field of sewage treatment, can solve the problems of difficult to guarantee the treatment effect, insufficient aeration amount, and large oxygen consumption, and achieve stable operation, good aeration effect, and improved treatment effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

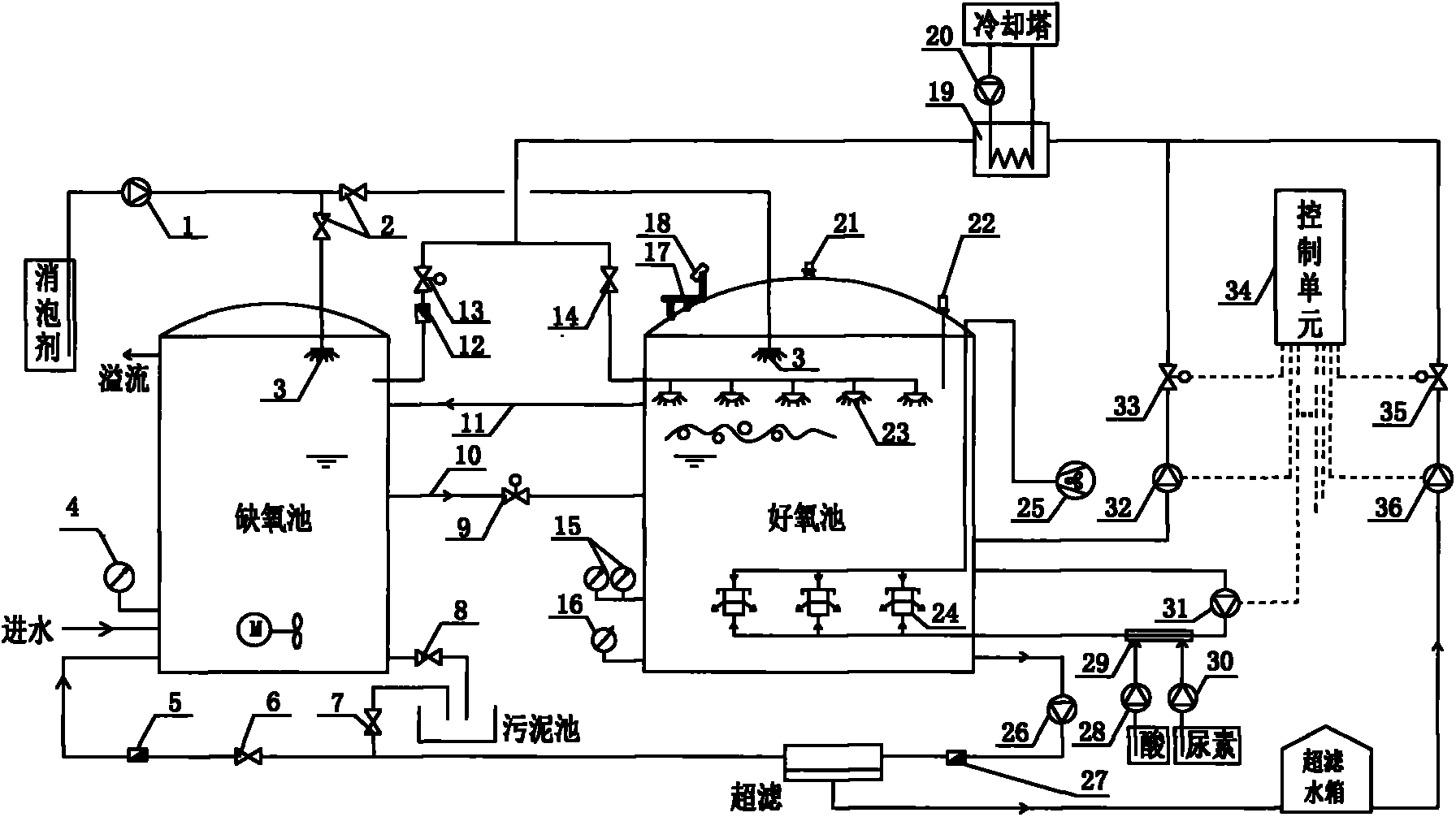

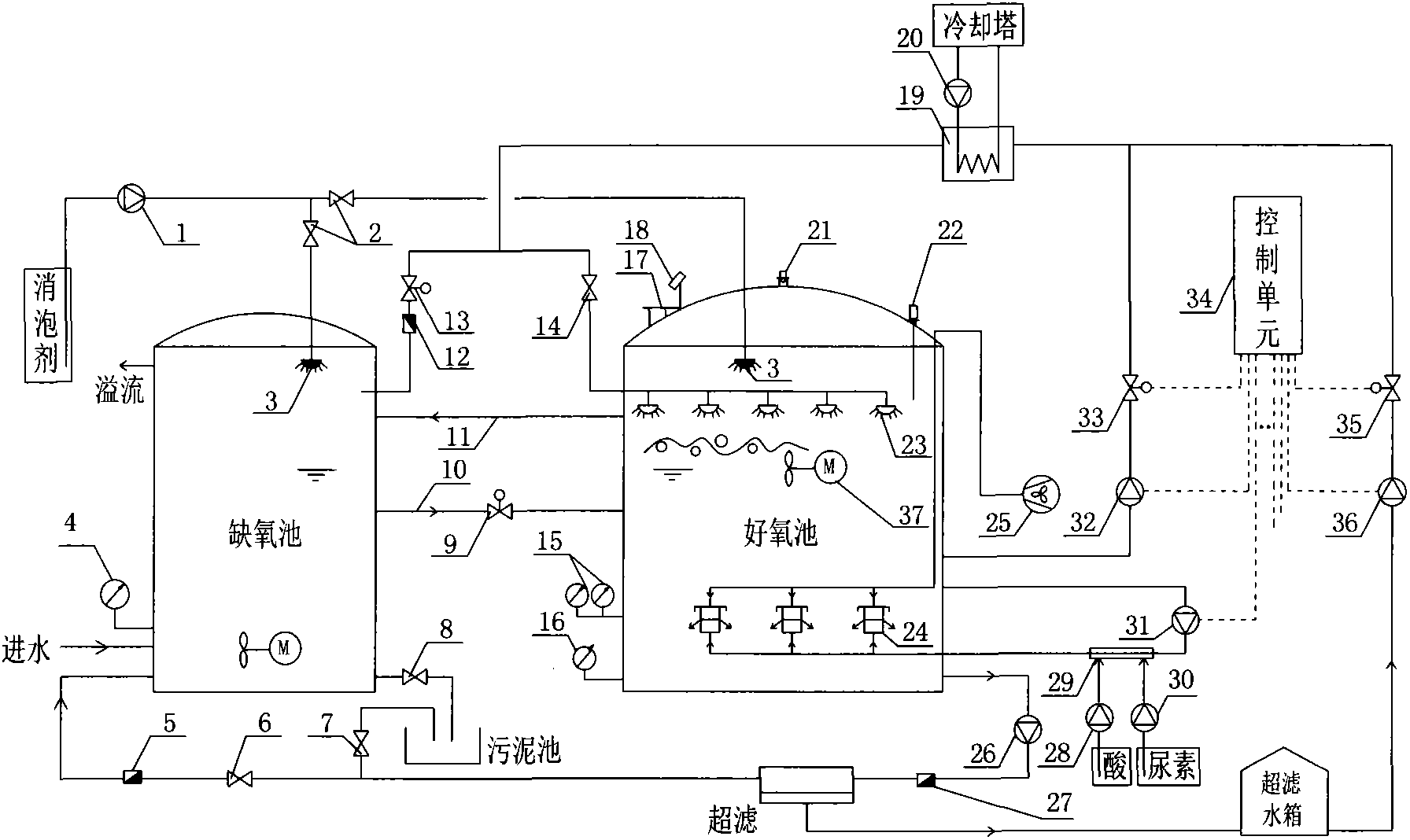

[0015] The invention relates to a precise aeration and combined defoaming process scheme for garbage leachate treatment, which is characterized in that it includes three parts: a precise aeration subsystem, a combined defoaming subsystem and an electrical automatic control subsystem.

[0016] as attached figure 1 As shown, the main equipment of the precision aeration subsystem includes: blower 25, jet aeration head 24, jet pump 31 and so on. The jet aeration heads 24 are evenly distributed at the bottom of the aerobic tank, ensuring that each aeration head has the same service area and uniform aeration. The blower 25 and the jet pump 31 all adopt frequency conversion control, and the frequency converter is installed in the electrical control cabinet. When implementing the present invention, according to the numerical value that dissolved oxygen analyzer 15 shows, can manually or by software automatically judge the increase or decrease of the required aeration volume of aerob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com