A method for preparing porous calcium phosphate bioceramic material

A bioceramic material, porous calcium phosphate technology, applied in the field of materials and biomedicine, can solve the problems of easy inflammation, residual plastic particles, complicated process, etc., achieve uniform pore size and pore distribution, simple method and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

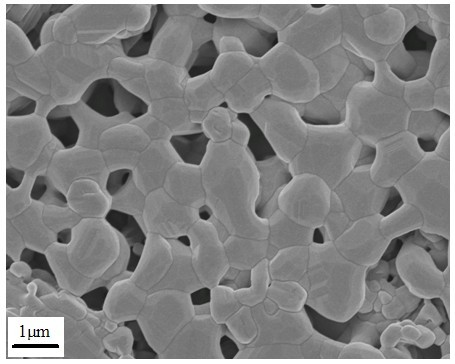

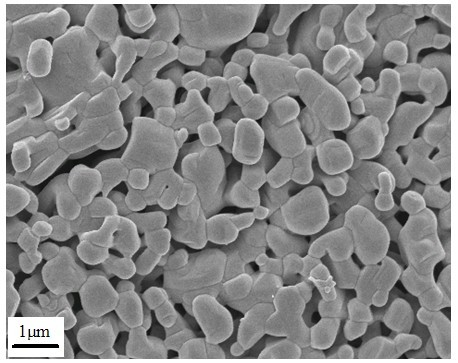

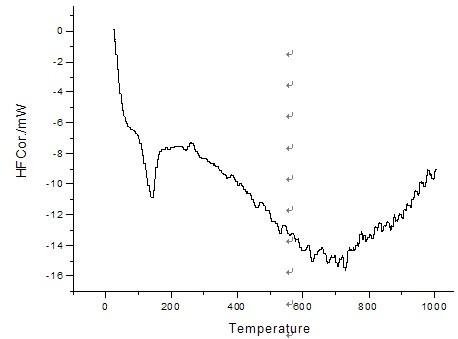

[0040] Put the OCP (octacalcium phosphate) powder into a stainless steel mold, compact it under the condition of a pressure of 20MPa, and then keep it under this pressure for 10 minutes, and then take out the green body; o The heating rate of C / min rises to 300 o Sintering at C, vaporization to remove crystal water, keep it at this temperature for 2h and then heat to 900 o C undergoes a phase change and then is naturally cooled in the furnace to obtain β-TCP porous bioceramics with a pore diameter of 1 to 5 μm and a porosity of 22%.

Embodiment 2

[0042] Put DCPD (calcium hydrogen phosphate dihydrate) powder into a stainless steel mold, compact it under the condition of a pressure of 20MPa, and then keep it under this pressure for 10 minutes, and then take out the green body; o The heating rate of C / min rises to 300 o Sintering at C, vaporization to remove crystal water, keep it at this temperature for 2h and then heat to 900 o C undergoes a phase change, and then is naturally cooled in the furnace to obtain porous HA bioceramics with a pore diameter of 1 to 5 μm and a porosity of 37%.

Embodiment 3

[0044] The OCP and DCPD powders are mixed in a ratio of 1:1, the mixed powder is put into a stainless steel mold, and compacted under the condition of a pressure of 20 MPa, and then kept under the pressure for 10 minutes, and the green body is taken out; the result is obtained after compaction The body is 20 o The heating rate of C / min rises to 300 o Sintering at C, vaporization to remove crystal water, keep it at this temperature for 2h and then heat to 900 o C undergoes a phase change and then is naturally cooled in the furnace to obtain β-TCP and HA dual-phase porous bioceramics with a pore diameter of 1 to 5 μm and a porosity of 29%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com