Acetylglutamine compound and pharmaceutical composition thereof

An acetoglutamine and compound technology, applied in the field of acetoglutamine compounds and pharmaceutical compositions thereof, can solve the problems of limiting the practical application of acetoglutamine preparations, reducing the yield of acetoglutamine, being unable to carry out industrialized production, etc., and achieving stable properties. , not easy to hydrolysis and oxidation, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] [Example 1] Preparation of Acetylglutamine Compound

[0054] 1) dissolving acetylglutamine powder in water to obtain solution 1;

[0055] 2) Under stirring, add ethanol dropwise to solution 1, the volume ratio of the amount of ethanol added to the water in solution 1 is 1:5-1:10 to obtain suspension 2;

[0056] 3) Suspension 2 is filtered, the filter cake is washed with ethanol, and dried to obtain the acetylglutamine compound.

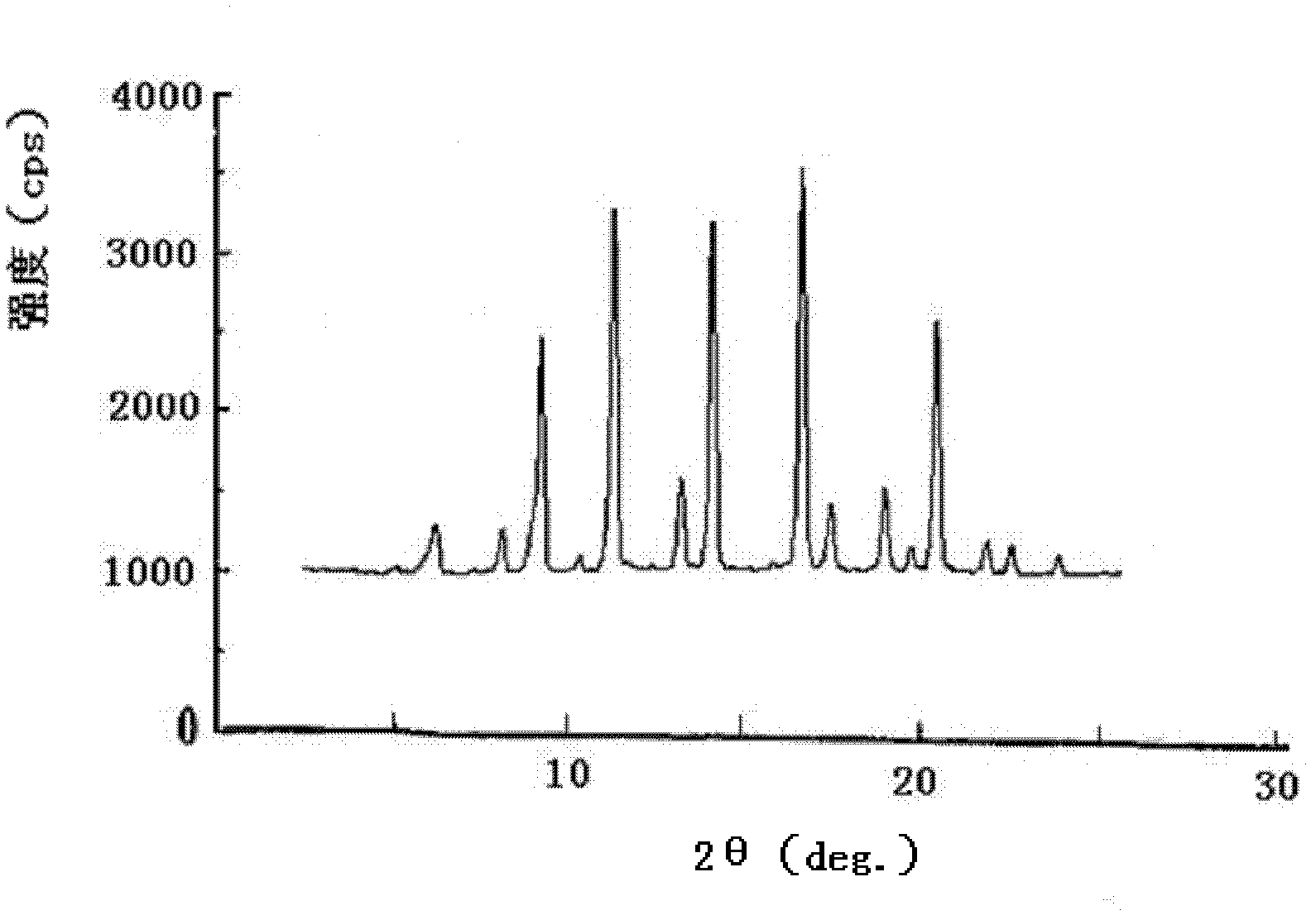

[0057] The particle diameter of the prepared acetylglutamine compound is 170 μm, and the X-ray powder diffraction pattern (see figure 1 ) in the characteristic peaks at 2θ of 9.3, 11.2, 14.6, 17.0, 20.9 show. The melting point is 150-152°C.

Embodiment 2

[0058] [embodiment 2] the preparation of acetylglutamine compound

[0059] 1) Dissolve 120g of acetylglutamine powder in 20ml of water to obtain solution 1;

[0060] 2) Under stirring at 1200 rpm, add 70ml of ethanol dropwise to solution 1 at a rate of 1.5ml / min. During the dropwise addition, the temperature of solution 1 is controlled at 25°C to obtain suspension 2. After the addition of ethanol is completed, continue to stir the suspension for 24 Hour;

[0061] 3) Suspension 2 was filtered, the filter cake was washed with ethanol, and vacuum-dried under reduced pressure at 25° C. for 18 hours to obtain the acetylglutamine compound.

[0062] The obtained acetylglutamine compound has a particle size of 180 μm and a melting point of 150-152° C. The X-ray powder diffraction pattern obtained by Cu-K α-ray measurement is consistent with that of Example 1.

Embodiment 3

[0063] [Example 3] Preparation of Acetylglutamine Compound

[0064] 1) Dissolve 40g of acetylglutamine powder in 20ml of water to obtain solution 1;

[0065] 2) Under stirring at 1000 rpm, add 50ml of ethanol dropwise to solution 1 at a rate of 1.0ml / min. During the dropwise addition, the temperature of solution 1 is controlled at 30°C to obtain suspension 2. After the addition of ethanol is completed, continue to stir suspension 2 3.5 hours;

[0066] 3) Suspension 2 was filtered, the filter cake was washed with ethanol, and vacuum-dried under reduced pressure at 20° C. for 12 hours to obtain the acetylglutamine compound.

[0067] The obtained acetylglutamine compound has a particle size of 160 μm and a melting point of 151-153° C. The X-ray powder diffraction pattern obtained by Cu-K α-ray measurement is consistent with that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com