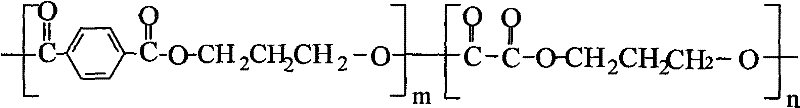

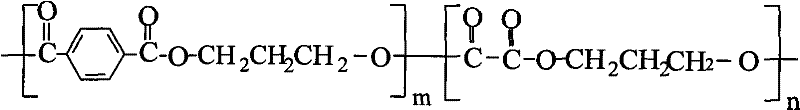

Preparation method of polyethylene terephthalate ethylene glycol copolyester

A technology of poly(trimethylene terephthalate) copolyester and terephthalate, applied in the field of preparation of poly(trimethylene terephthalate) copolyester, capable of solving problems such as difficult direct copolymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 182 parts of terephthalic acid (parts by mass), 353 parts of 1,3-propanediol, 194 parts of dimethyl oxalate, 0.12 parts of ethylene glycol antimony and 0.15 parts of tetrabutyl titanate in the batch reactor, at 220 ~ Esterification and transesterification at 250°C and a pressure of 0.25MPa (gauge pressure). The esterification is completed when the water output reaches the theoretical water output. The pressure of the reactor is released to normal pressure. After adding 0.025 parts of trimethyl phosphate, it is transferred to the belt The double-conical polymerization kettle with disc stirring gradually decompresses and heats up. After 45 minutes, the vacuum of the polymerization kettle reaches 90Pa (absolute pressure), and the reaction temperature is maintained at 240-250℃. After 170 minutes of polymerization, the polymerization is completed when the rated stirring power is reached. For polymerization reaction, use nitrogen to eliminate the vacuum, cool with water, a...

Embodiment 2

[0040] Add 330 parts of terephthalic acid, 270 parts of 1,3-propanediol, 12.5 parts of dimethyl oxalate, 0.12 parts of ethylene glycol antimony and 0.15 parts of tetrabutyl titanate into the batch reactor, at 220~250℃, pressure Esterification and transesterification under 0.25MPa (gauge pressure), the esterification is completed when the water output reaches 95% of the theoretical water output, the pressure of the reactor is released to normal pressure, and after adding 0.025 parts of trimethyl phosphate, it is transferred to a Stirring biconical polymerization kettle, gradually decompress and heat up. After 45 minutes, the vacuum of the polymerization kettle reaches 90Pa, and the reaction temperature is maintained at 240-250°C. After 150 minutes of polymerization, the polymerization reaction is completed when the rated stirring power is reached, and the vacuum is eliminated with nitrogen. , after water cooling, pelletizing can obtain a polyethylene terephthalate ethylene glyco...

Embodiment 3

[0042] 83 parts of dimethyl oxalate and 108 parts of 1,3-propanediol, 0.07 parts of manganese acetate are first transesterified at 150-220 ° C, and then with 272 parts of terephthalic acid, 212 parts of 1,3-propanediol, 0.12 parts Ethylene glycol antimony and 0.15 parts of tetrabutyl titanate are esterified at 220-250 ° C and a pressure of 0.25 MPa (gauge pressure). The esterification is completed when the water output reaches 95% of the theoretical water output, and the pressure of the reactor is released to normal. After adding 0.025 parts of triethyl phosphate, transfer to a biconical polymerization kettle with disk stirring, gradually reduce the pressure and increase the temperature. After 45 minutes, the vacuum of the polymerization kettle reaches 90Pa, and the reaction temperature is maintained at 240-250℃. After 160 minutes of polymerization, when the rated stirring power is reached, the polymerization reaction is terminated, and the vacuum is eliminated with nitrogen, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com