Extracts containing β-1,3-d-glucan and uses thereof

An extract, glucan technology, applied in the directions of medical preparations containing active ingredients, applications, microorganisms, etc., can solve the problems of large molecular weight and low purity, and achieve the effect of inhibiting tumors, promoting metabolism, and improving skin rejuvenation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

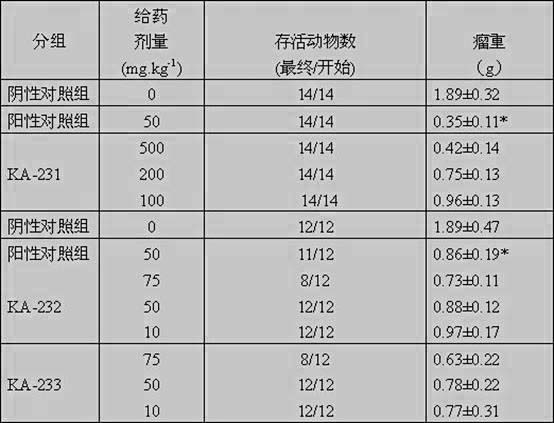

Embodiment 1

[0038] Crush 10kg of dried Hydrangea to 80 mesh, add it to a 200L autoclave, add 50kg of phosphate buffer solution (pH value is 7.3, specifically prepared as disodium hydrogen phosphate 1.97 g and potassium dihydrogen phosphate 0.22 g, add water to dissolve into 1000 mL, adjust the pH value to 7.3), stir evenly, heat to 121°C, keep warm for 30 minutes, sterilize the material, then quickly cool the material to 30°C, add 100g β-1,3 glucosidase , Stir evenly, hydrolyze for 3 hours, hydrolyze the macromolecule β-1,3 glucan into β-1,3 glucan with a specific molecular weight, and vacuum-dry the hydrolyzed slurry at 45°C to control the moisture content below 12% , to obtain the extract, which contains 45% of β-1,3-D-glucan with a molecular weight of 200,000-500,000 Daltons. The extract is ultra-low temperature pulverized into a 180-mesh ultra-fine powder, which is recorded as: KA-231.

Embodiment 2

[0040] Crush 10kg of dried Hydrangea to 80 mesh, add it to a 200L autoclave, add 50kg of phosphate buffer (pH value is 7.3, specifically prepared as disodium hydrogen phosphate 1.97 g and potassium dihydrogen phosphate 0.22 g, add water to dissolve into 1000 mL, adjust the pH value to 7.3), stir evenly, heat to 121°C, keep warm for 30 minutes, sterilize the material, then quickly cool the material to 30°C, add 100g β-1,3 glucoside Enzyme, stir evenly, hydrolyze for 3 hours, hydrolyze macromolecular β-1,3 glucan into β-1,3 glucan with specific molecular weight, add 70kg of water, boil for 2 hours, filter, and add the filter residue 100kg of water, boiled and extracted for 2 hours, filtered. The combined filtrate was concentrated in vacuum at 70°C to 50kg, added ethanol until the concentration of ethanol reached 65% (v / v), stirred evenly, stood for 2 hours, centrifuged at 3,000rpm for 5 minutes, discarded the precipitate, and continued to the supernatant Add ethanol until the e...

Embodiment 3

[0042] The KA-232 obtained in Example 2 was separated and purified by Sephadex G-100 gel chromatography, the eluent was 0.1M NaCl solution, the elution peak was monitored by the phenol+sulfuric acid method, and the single peak part was combined, followed by concentration, dialysis and Ethanol precipitation to obtain an extract, which contains 80% β-1,3-D-glucan with a molecular weight of 200,000-500,000 Daltons. After natural drying, a white or off-white powder is obtained, which is recorded as: KA-233.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com