A kind of tin-containing ferritic stainless steel plate and its manufacturing method

A technology of stainless steel plate and tin ferrite, which is applied in the field of tin-containing ferritic stainless steel plate and its manufacture, can solve the problems of easy cracking of stainless steel, increase the amount of steel billet grinding, reduce the Sn content of ferritic stainless steel, etc., and achieve good Formability and corrosion resistance, improvement of hot workability, and good formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

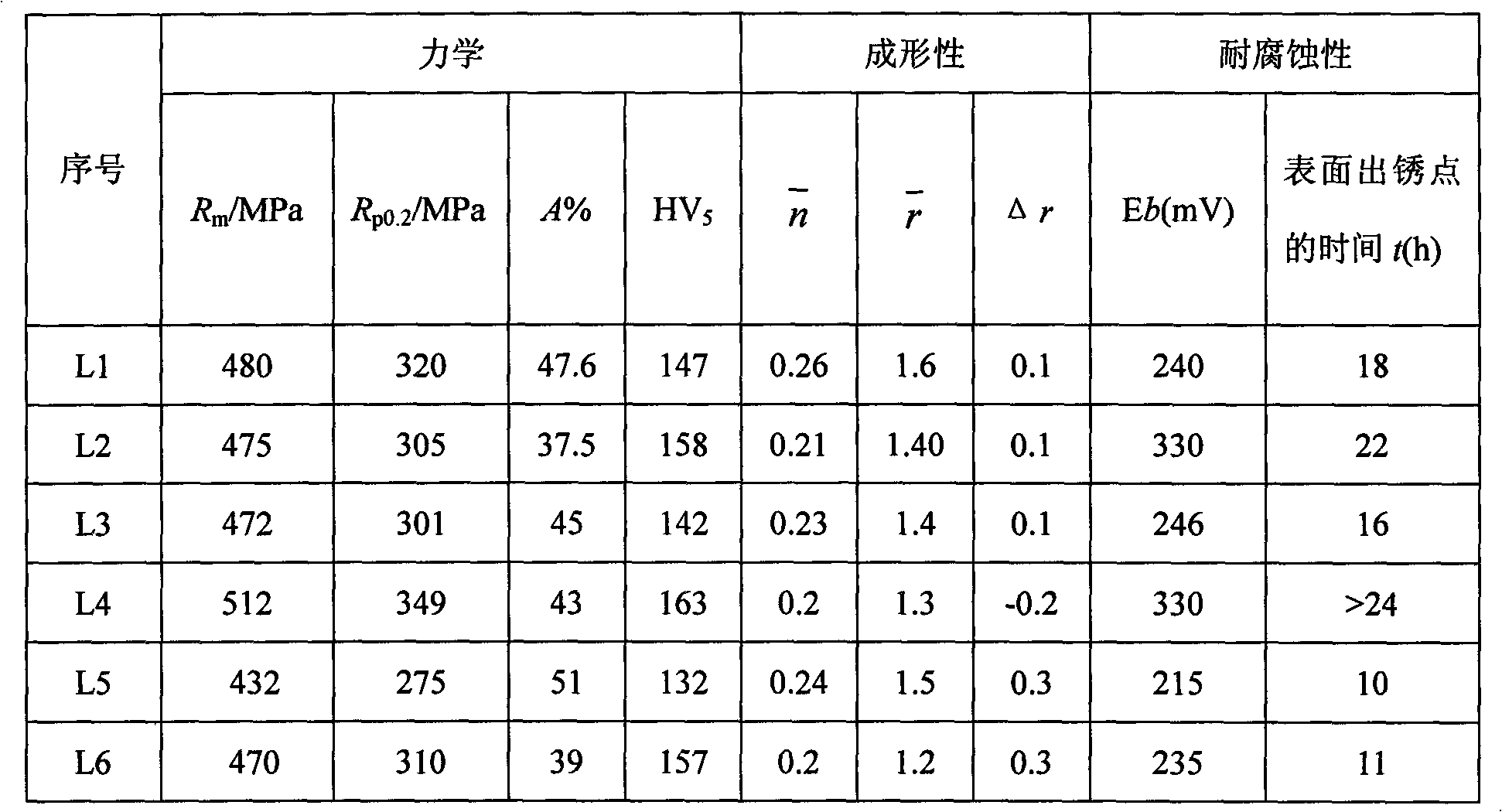

Examples

Embodiment 2

[0052] The thickness of the cold-rolled plate is 1mm, and the mass percentage of its composition is:

[0053] C 0.0032%; N 0.0081%; Al 0.01%; Si 0.46%;

[0054] Mn 0.09%; Cr 17.05%; P 0.008%; S 0.009%;

[0055] Ni 0.2%; Cu 0.005%; Mo 0.005%; Sn 0.33%;

[0056] Ti 0.12%; Nb 0.12%; Ga 0.01%; Pr 0.05%;

[0057] Nd 0.15%; and 0.55(Pr+Nd)+1.14Ga>2S.

[0058] The rest is Fe and unavoidable impurities.

[0059] The tin-containing ferritic stainless steel plate in this example has a grain size of grade 8 and a {111} orientation texture.

[0060] Example 3 of tin-containing ferritic stainless steel plate

[0061] The thickness of the cold-rolled plate is 0.6mm, and the mass percentage of its composition is:

[0062] C 0.005%; N 0.0056%; Al 0.3%; Si 0.02%; Mn 0.1%;

[0063] Cr 12.5%; P 0.005%; S 0.008%; Ni 0.2%; Cu 0.03%;

[0064] Mo 0.1%; Sn 0.1%; Ti 0.3%; Nb 0.01%; Ga 0.1%;

[0065] La 0.036%; Ce 0.051%; Pr 0.005%; Nd 0.008%;

[0066] And 0.55(La+Ce+Pr+Nd)+1.14Ga>2S. The re...

Embodiment 3

[0135] What this method embodiment manufactured was the product of the tin-containing ferritic stainless steel plate embodiment three, and its main manufacturing steps were as follows:

[0136] Smelting means that the pretreated molten iron is smelted into molten steel by a converter, and then refined by a vacuum oxygen blowing decarburization furnace (VOD furnace) and a ladle refining furnace (LF furnace). Add pure tin, pure gallium and La-Ce-Pr-Nd mixed rare earth alloy, (add 1kg of pure tin per ton of molten steel; 1kg of pure gallium; 1kg of La-Ce-Pr-Nd mixed rare earth alloy):

[0137] C 0.005%; N 0.0056%; Al 0.3%; Si 0.02%; Mn 0.1%;

[0138] Cr 12.5%; P 0.005%; S 0.008%; Ni 0.2%; Cu 0.03%;

[0139] Mo 0.1%; Ti 0.3%; Nb 0.01%; the rest is Fe and unavoidable impurities. The molten steel temperature is 1610±10°C.

[0140] After adding pure tin, pure gallium and La-Ce-Pr-Nd mixed rare earth alloy, the mass percentage of the composition of molten steel reaches the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com