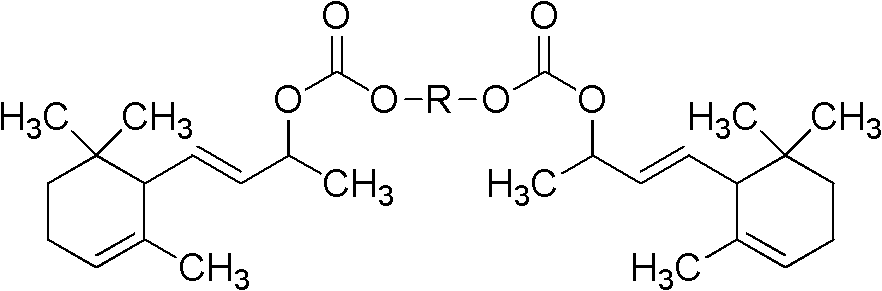

Monosaccharide alpha-ionol carbonic acid di-ester compound as well as preparation method and application thereof

A technology of carbonic diester and ionol, which is applied in the field of monosaccharide ester cigarette moisturizing agent, monosaccharide α-ionol carbonic diester compound and new cigarette moisturizing agent, and can solve the problem of loss of flavor, uneven flavor release, etc. Easy to lose and other problems, to achieve the effect of slowing down changes, comfortable and harmonious aroma, and slowing down volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

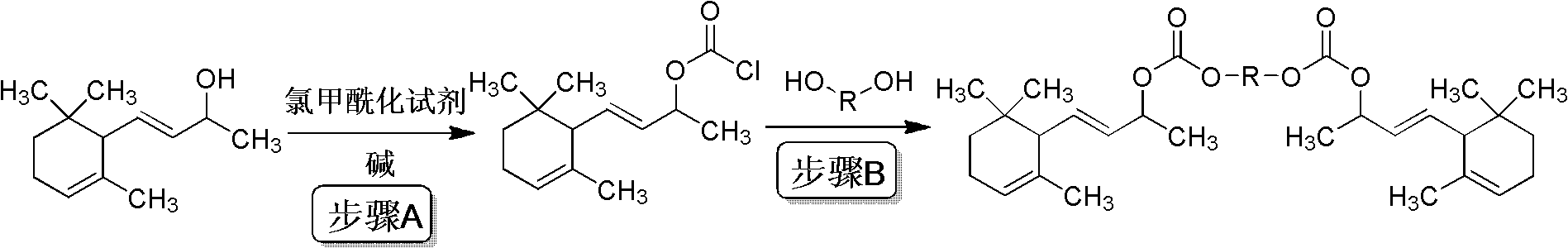

[0035] Embodiment 1: Synthesis of chloroformic acid-α-ionyl ester

[0036] Add 2000ml CH to the reaction flask 2 Cl 2 and bis(trichloromethyl)carbonate 129g (0.44mol), stirred at room temperature until the solids were completely dissolved, put the reaction bottle in an ice-salt bath, cooled to -10°C, added α-ionol 1.28mol, completely After dissolving, add 200ml of pyridine dropwise, control the rate of addition, and keep the temperature of the reaction solution at 0-5°C. After dropping, the reaction solution is naturally warmed to room temperature, and stirred overnight to obtain dichloroformic acid-α-ionyl ester. Chloromethane solution can be used in the next step reaction without purification, and the yield is quantitative.

Embodiment 2

[0037] Embodiment 2: Synthesis of chloroformic acid-α-ionyl ester

[0038]The operation process is the same as in Example 1, except that bis(trichloromethyl)carbonate diester is replaced with trichloromethyl chloroformate, and pyridine is replaced with sodium bicarbonate, CH 2 Cl 2 Substitute toluene to obtain a toluene solution of chloroformic acid-α-ionyl ester, which can be used in the next reaction without purification, and the yield is quantitative.

Embodiment 3

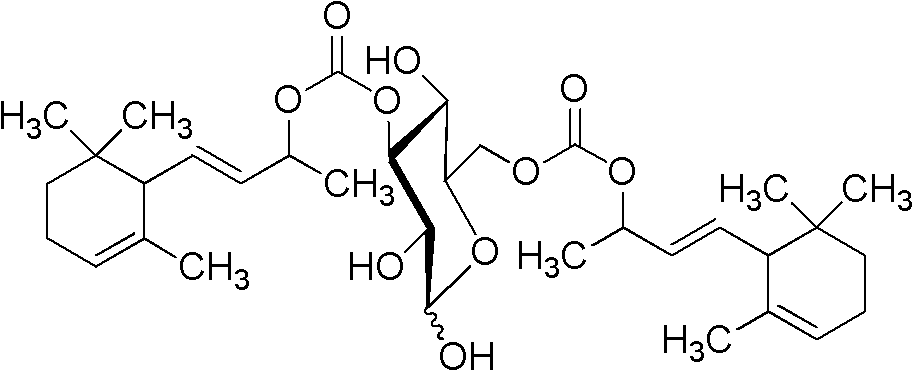

[0039] Example 3: Preparation of 3,6-di-O-α-ionol carbonyl-D-glucopyranose carbonate (Compound I)

[0040]

[0041] Take 0.15 mol of the chloroformic acid-α-ionol ester methylene chloride solution prepared in Example 1, and add dropwise 9.7 g (0.05 mol) of D-glucosylmethyl glycoside, 20.2 g of triethylamine, which has been cooled to -5 to 0° C. g (0.20mol) and dichloromethane 100ml mixed solution, stirred at room temperature for 13h, after the reaction, filtered out solid, the filtrate was evaporated to remove the solvent under reduced pressure, the residue was dissolved in 200ml of dichloromethane, and 40ml of 20% hydrochloric acid aqueous solution was added , stirred at room temperature for 1.5h, the organic layer was washed successively with saturated aqueous sodium carbonate solution 50ml and saturated brine 50ml, and the obtained dichloromethane solution was washed with anhydrous Na 2 SO 4 Dry, filter, dichloromethane is distilled off under reduced pressure, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com