Semiconductor structure and method for manufacturing semiconductor device

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problem of increasing tape residues, and achieve the effect of reducing pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will provide many different embodiments to implement different features of the present invention. However, these examples are not intended to limit the present invention. The specific embodiments discussed below are only used to illustrate the manufacture and use of the embodiments of the present invention, but do not limit the scope of the present invention.

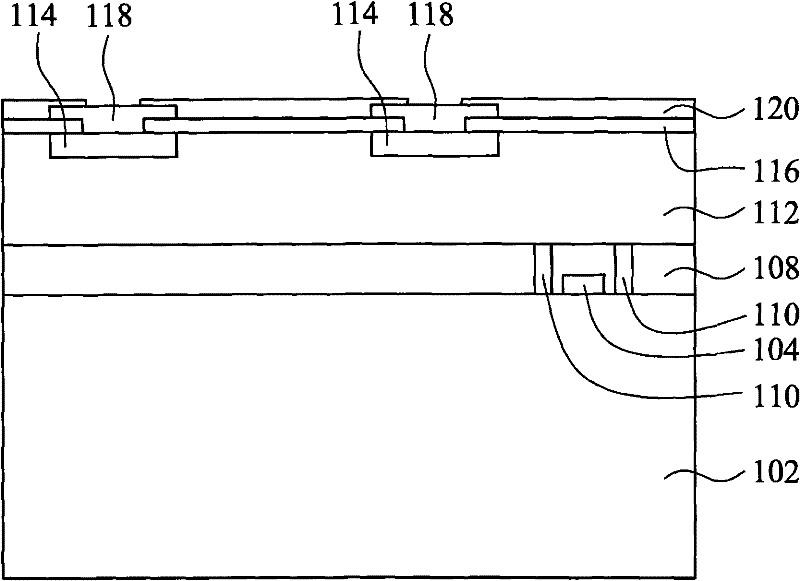

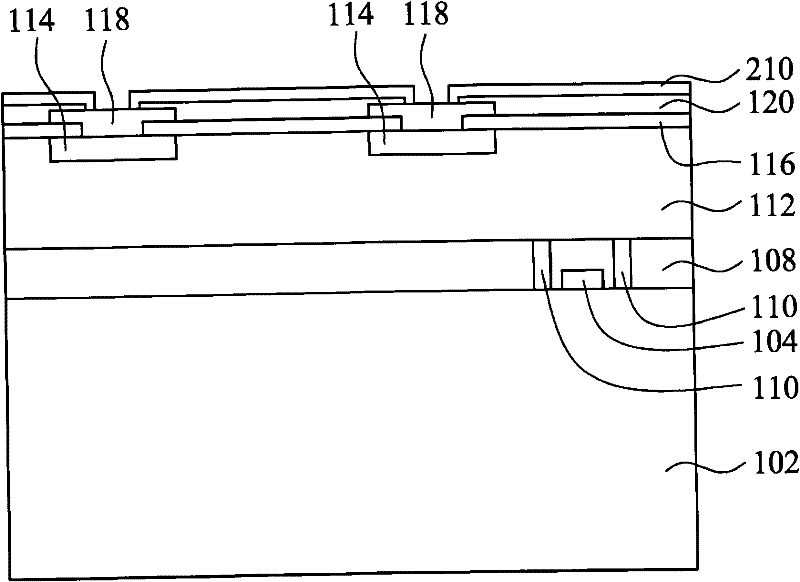

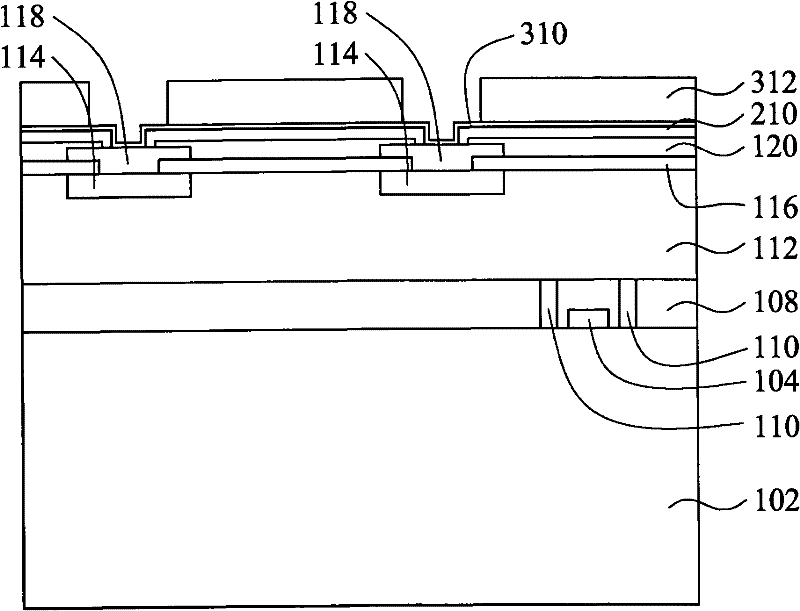

[0026] Embodiments described herein relate to a two-step plasma treatment for polymer surfaces to provide a contaminant-free surface for use in semiconductor devices. As discussed below, embodiments of the present invention disclose the use of a first plasma treatment process from the surface of the substrate to roughen the surface of the polymer layer and loosen the structure of metal contaminants for subsequent etching to remove the contaminants, and using The second plasma treatment process makes the surface smoother, wherein the substrate can be a die, a wafer, a printed circuit board, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com