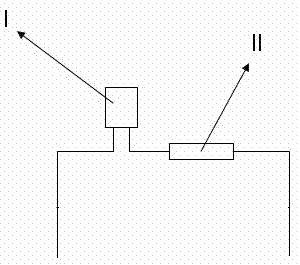

Nano polyaniline composite surface acoustic wave humidity sensor and manufacturing method thereof

A nano-polyaniline, humidity sensor technology, applied in the process of producing decorative surface effects, using sonic/ultrasonic/infrasonic waves to analyze fluids, and manufacturing microstructure devices, etc. Insufficient research on humidity sensing elements, etc., to achieve the effects of good response linearity, improved response sensitivity, and high response sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

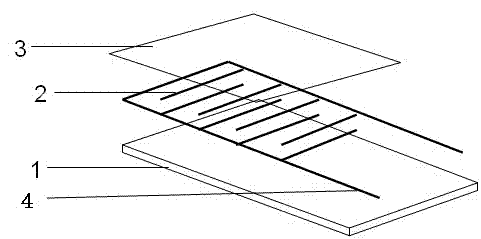

[0030] 1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0031] 2) Prepare an aqueous solution of polystyrene sulfonic acid with a concentration of 0.1 g / ml, add aniline to it, and add 4 ml of aniline per liter of polystyrene sulfonic acid aqueous solution, at -20 ? Stir at C for 1 hour, then add an aqueous solution with a concentration of 0.05 g / ml ammonium persulfate, the volume ratio of polystyrene sulfonic acid aqueous solution to ammonium persulfate aqueous solution is 1: 1, after stirring and mixing, let stand for 12 hours, and use acetone precipitation, suction filtration, washing with acetone, and vacuum drying at room temperature to obtain polyaniline nanoparticles;

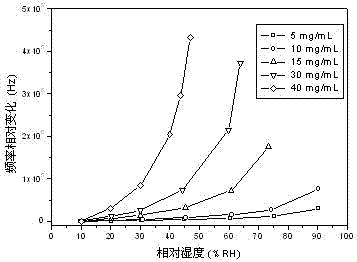

[0032] 3) Prepare the polyaniline nanoparticles prepared in step 2) into an aqueous solution with a concentration of 15 mg / ml, and mix it with an aqueous solution of polyvinyl alcohol with a concentration of 15 mg / ml...

Embodiment 2

[0036] 1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0037] 2) Prepare an aqueous solution of polystyrene sulfonic acid with a concentration of 0.5 g / ml, add aniline to it, and add 15 ml of aniline per liter of polystyrene sulfonic acid aqueous solution, at -10 ? Stir at C for 2 hours, then add an aqueous solution with a concentration of 0.1 g / ml ammonium persulfate, the volume ratio of polystyrene sulfonic acid aqueous solution to ammonium persulfate aqueous solution is 1: 1.5, after stirring and mixing, let it stand for 16 hours, and use acetone precipitation, suction filtration, washing with acetone, and vacuum drying at room temperature to obtain polyaniline nanoparticles;

[0038] 3) The polyaniline nanoparticles prepared in step 2) are configured into an aqueous solution with a concentration of 20 mg / ml, and mixed with an aqueous solution of polyvinyl alcohol with a concentration...

Embodiment 3

[0042] 1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0043] 2) Prepare an aqueous solution of polystyrene sulfonic acid with a concentration of 1.5 g / ml, add aniline to it, and add 20 ml of aniline per liter of polystyrene sulfonic acid aqueous solution, at 0 ? Stir at C for 3 hours, then add an aqueous solution with a concentration of 0.15 g / ml ammonium persulfate, the volume ratio of polystyrene sulfonic acid aqueous solution to ammonium persulfate aqueous solution is 1: 2, after stirring and mixing, let it stand for 20 hours, and use acetone precipitation, suction filtration, washing with acetone, and vacuum drying at room temperature to obtain polyaniline nanoparticles;

[0044] 3) The polyaniline nanoparticles prepared in step 2) are configured into an aqueous solution with a concentration of 25 mg / ml, and mixed with an aqueous solution of polyvinyl alcohol with a concentration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com