Slurry and method for preparing cuprous sulfide counter electrode in sensitized solar cell

A technology of cuprous sulfide and solar cells, which is applied in the direction of capacitor electrodes, sulfide conductors, electrolytic capacitors, etc., can solve the problems of unstable battery performance, difficulty in sealing, and high cost, so as to facilitate battery packaging, reduce manufacturing costs, and enhance stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] [Example 1]: Preparation of cuprous sulfide counter electrode in situ

[0023] Use solvothermal method to deposit cuprous sulfide in situ on the surface of transparent conductive glass. The reaction conditions are ethylene glycol as solvent, 20mM copper acetate and 10mM thiourea as reactants, solvothermal deposition at 180°C for 5 hours; then take out Transparent conductive glass, washed with pure water and then vacuum-dried at 60°C for 12 hours to obtain a cuprous sulfide counter electrode.

[0024] The counter electrode of the above-mentioned embodiment 1 is assembled into a battery for photoelectric conversion efficiency testing, wherein the photoanode is a porous nano-titanium dioxide film, the sensitized quantum dots are CdS and CdSe, and the electrolyte is an aqueous solution of 1M sodium sulfide and 1M elemental sulfur. The test results As shown in Table 1. As a comparison, platinum (pyrolysis method), gold (thermal evaporation), carbon (scratch coating method) ...

Embodiment 2~51

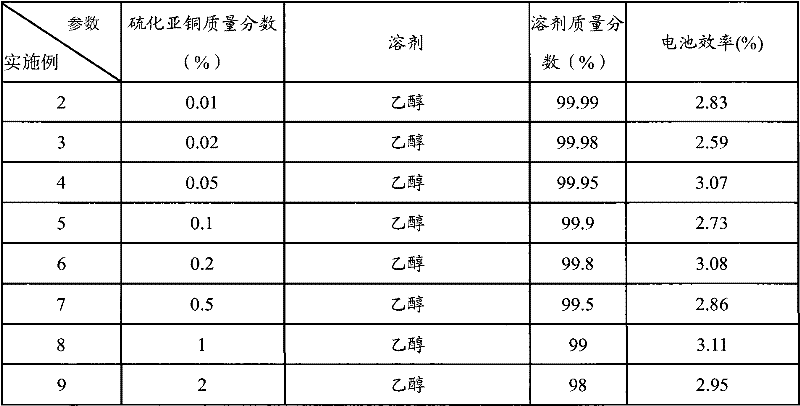

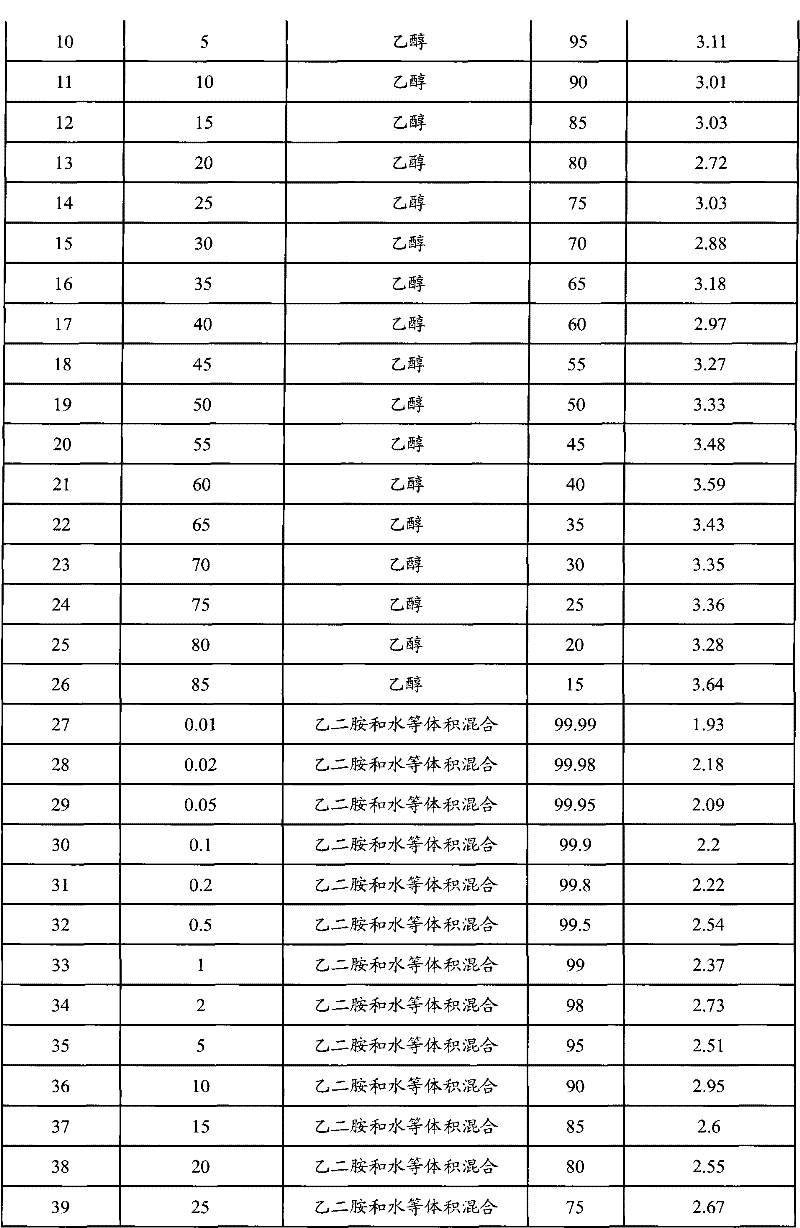

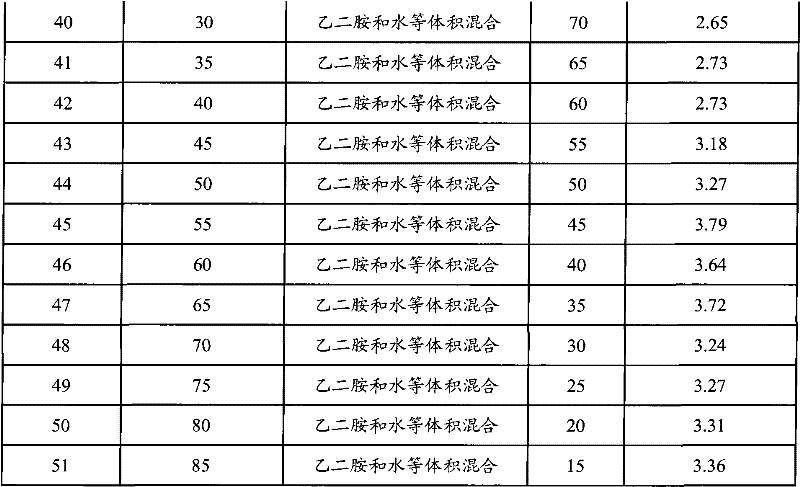

[0028] [Example 2-51]: Using a slurry containing cuprous sulfide to prepare a cuprous sulfide counter electrode

[0029] Disperse cuprous sulfide in different types and contents of solvents according to the different mass fractions shown in Table 2 to prepare a slurry; then use high-pressure spraying to deposit the slurry on the surface of graphite paper heated to 120°C , to get the counter electrode. The counter electrode was assembled into a battery according to the method of the above-mentioned Example 1 to test its battery efficiency, and the results are as follows.

[0030] Table 2

[0031]

[0032]

[0033]

[0034] It can be seen from the above results that when the cuprous sulfide is deposited on the graphite substrate as the counter electrode, the battery performance is excellent, and the mass percentage is preferably 45% to 85%, more preferably 55% to 65%.

Embodiment 52~69

[0035] [Example 52-69]: Preparation of cuprous sulfide counter electrode using slurry containing cuprous sulfide, binder and surfactant

[0036] According to the ratio in Table 2, the slurry was prepared with glycerol as the solvent, and then screen-printed on the flexible ITO / PET, and dried at 80°C to prepare the cuprous sulfide counter electrode. The battery was assembled according to the method of the above-mentioned Example 1 to test the battery efficiency, and the test results are as follows.

[0037] table 3

[0038]

[0039]

[0040] The above Tx-100 is an abbreviation for TritonX 100, a commercially available surfactant manufactured by Sigma-Aldrich Corporation. The above data show that the counter electrode prepared under low temperature conditions also has good performance. This method is especially suitable for flexible substrates that are difficult to withstand high temperature treatment. At the same time, due to the presence of the binder, the bond between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com