A method for improving frequency characteristics of algan/gan HEMT

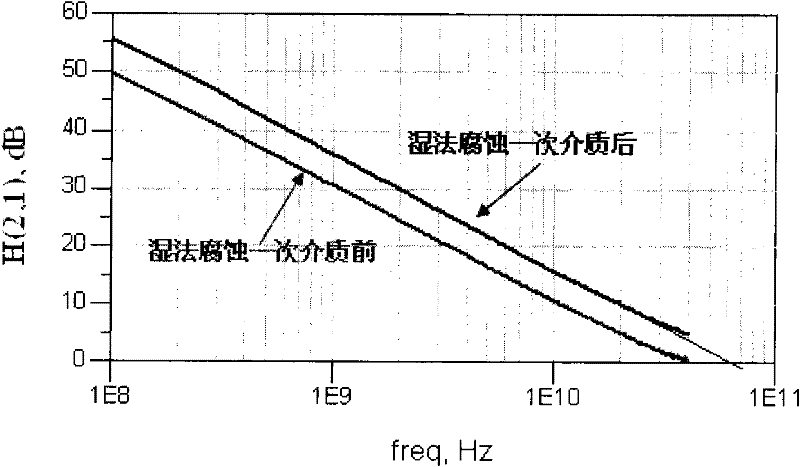

A technology of frequency characteristics and wet etching, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems affecting device frequency performance, increase, etc., to increase the highest oscillation frequency, increase the cut-off frequency, suppress The effect of the current collapse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

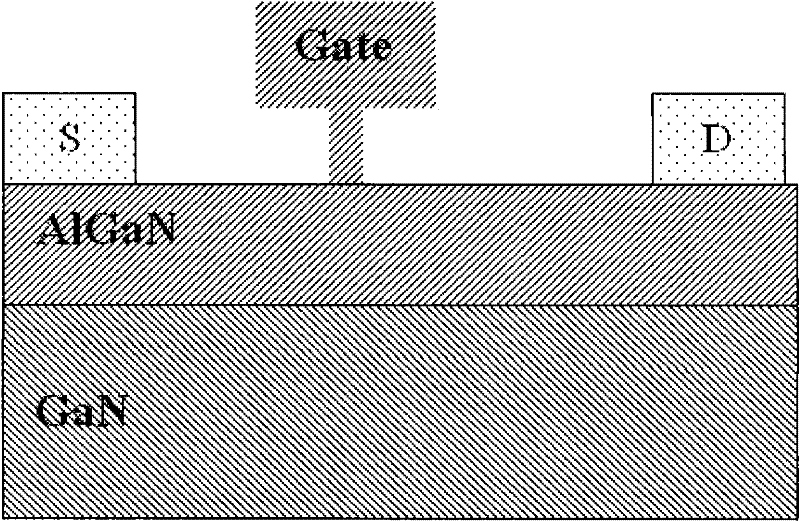

[0027] The present invention can be applied to GaN-based HEMT devices in the millimeter wave and frequency bands above the millimeter wave, and is now combined with figure 1 with figure 2 The present invention is described in detail:

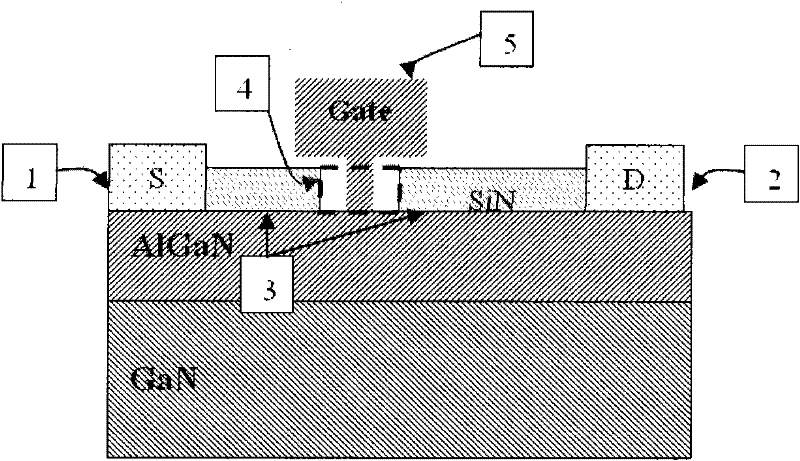

[0028] figure 1 It is a cross-sectional view of a GaN-based HEMT device structure with a conventional structure in the prior art. The formation process includes: forming the source electrode 1 and the drain electrode 2 by rapid annealing alloy; 3 N 4 3, the thickness is 1200 Through ICP etching, the gate groove 4 is formed; through electron beam direct writing, a T-shaped grid 5 is formed, the metal composition of the T-shaped grid is Ni / Au, and the thickness of the T-shaped grid foot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com