Polybenzimidazole polymer ion exchange membrane and its preparation and application

A polybenzimidazole, ion exchange membrane technology, applied in electrical components, circuits, fuel cell parts and other directions, can solve the problems of high requirements for experimental devices, harsh operating conditions, difficult processing, etc., to improve hydrophilicity. properties, mild preparation conditions, good solubility and film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]Dissolve 3.4 grams of phosphorus pentoxide in 34 grams of polyphosphoric acid, add it to a 500ml three-necked flask, heat up and stir to form a clear solution, then add 6mmol of biphenyltetramine, 6mmol of 4,4'-dicarboxydiphenyl ether , stirred and heated up to 200 degrees, after 20 hours of reaction, cooled down, poured into a solution containing 5% sodium hydroxide. After standing for 24 hours, wash well with water until the solution is neutral. Filter and dry. The prepared polymer was dissolved in DMSO to prepare a 4wt% solution, and the solution was cast onto a glass plate and flattened with a casting knife. After drying at 80°C for 20 hours, the membrane was removed from the glass plate. The dry polymer membrane was soaked in 4M sulfuric acid at room temperature for 5 hours to obtain a polybenzimidazole ion exchange membrane with a thickness of about 35 μm and no pyridine structural unit.

Embodiment 2

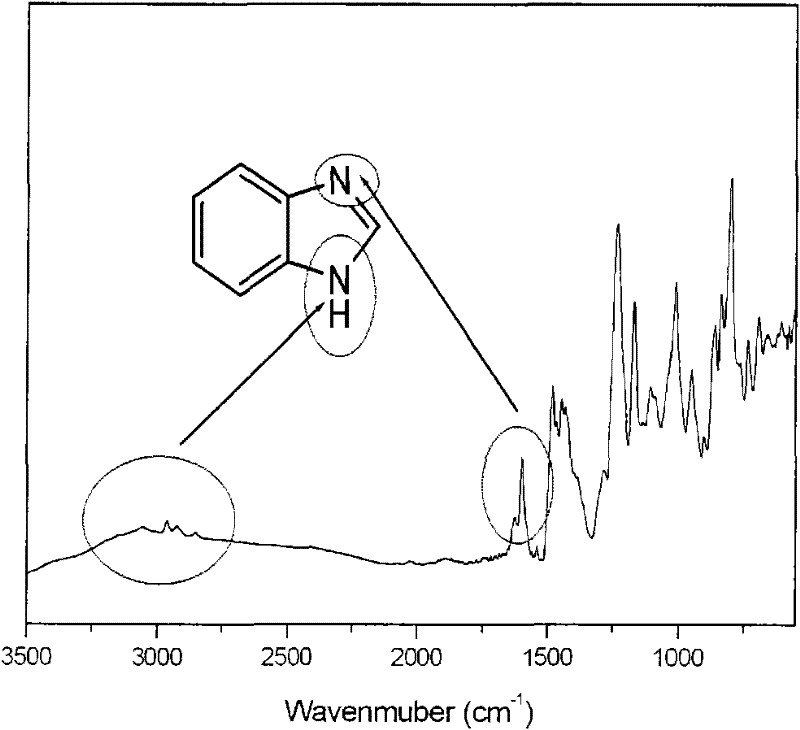

[0043] Dissolve 3.4 grams of phosphorus pentoxide in 34 grams of polyphosphoric acid, add it to a 500ml there-necked flask, heat up and stir to form a clear solution, then add 6mmol biphenyltetramine, 1.2mmol 2,6-pyridinedioic acid, 4.8 mmol 4,4'-dicarboxydiphenyl ether, stirred and heated up to 200 degrees, reacted for 20 hours, cooled down, and poured into a 5% sodium hydroxide solution. After standing for 24 hours, wash well with water until the solution is neutral. Filter and dry. The prepared polymer was dissolved in DMSO to prepare a 4wt% solution, and the solution was cast onto a glass plate and flattened with a casting knife. After drying at 80°C for 20 hours, the membrane was removed from the glass plate. The dry polymer membrane was soaked in 4M sulfuric acid at room temperature for 5 hours to obtain a polybenzimidazole ion exchange membrane with a thickness of about 35 μm and containing 20 wt% pyridine structural units. figure 1 For the preparation of infrared im...

Embodiment 3

[0045] Same as Example 2, the difference is that the membrane is soaked at room temperature for 3 days with 6M phosphoric acid instead of sulfuric acid, taken out and dried to obtain a polybenzimidazole ion exchange membrane with a thickness of 40 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com