A kind of marine biological antifouling paint and its preparation method and application

A technology for marine organisms and antifouling paints, applied to biocide-containing paints, antifouling/underwater paints, coatings, etc., can solve the problems of slow polymer solubility, environmental pollution, etc., and achieve long-term and wide application Prospects and economic value, the effect of preventing and controlling marine biofouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

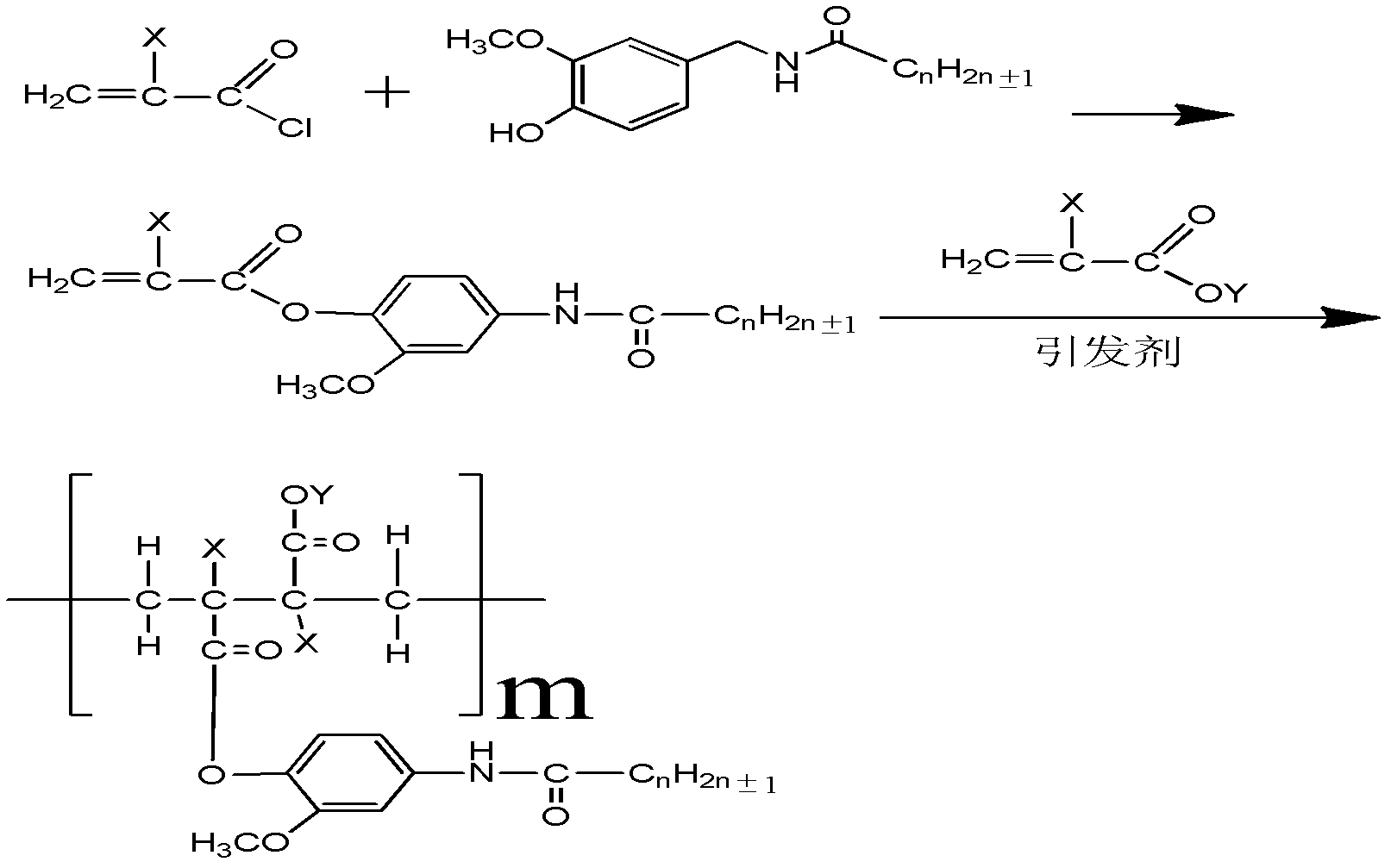

Method used

Image

Examples

Embodiment 1

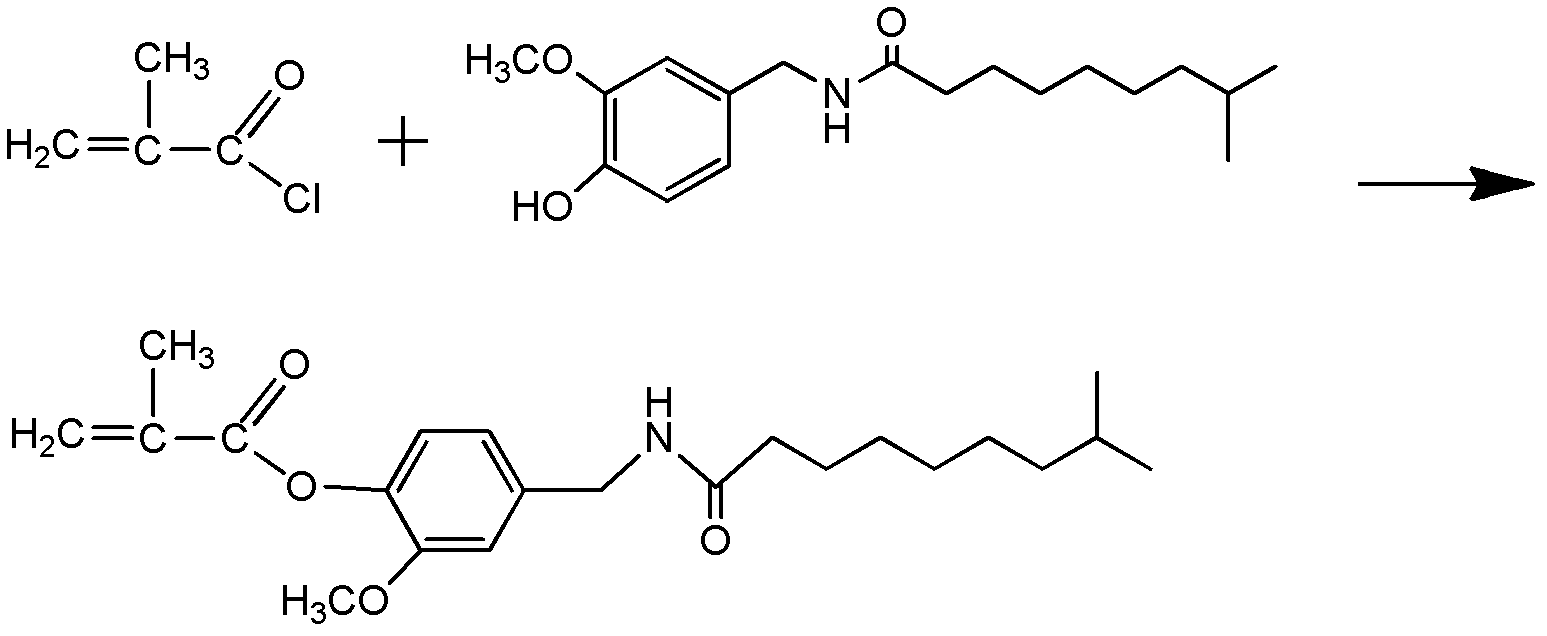

[0024] 1.5mol of dihydrocapsaicin (C 18 h 29 NO 3 ) was dissolved in 500ml anhydrous ether (C 4 h 10 After O), add 30ml diethylamine (C 4 h 11 N) solution (basic catalyst), add 1mol of methacryloyl chloride (C 4 h 5 OCl), then refluxed and stirred for 8 hours, distilled off methacryloyl chloride, ether and diethylamine under vacuum (0.1bar, 70°C), then fractionated under vacuum (0.1bar) with a fractionating column, and collected 103~120 ℃ fraction, to obtain dihydrocapsaicin methacrylate, the preparation process is as follows figure 2 shown.

Embodiment 2

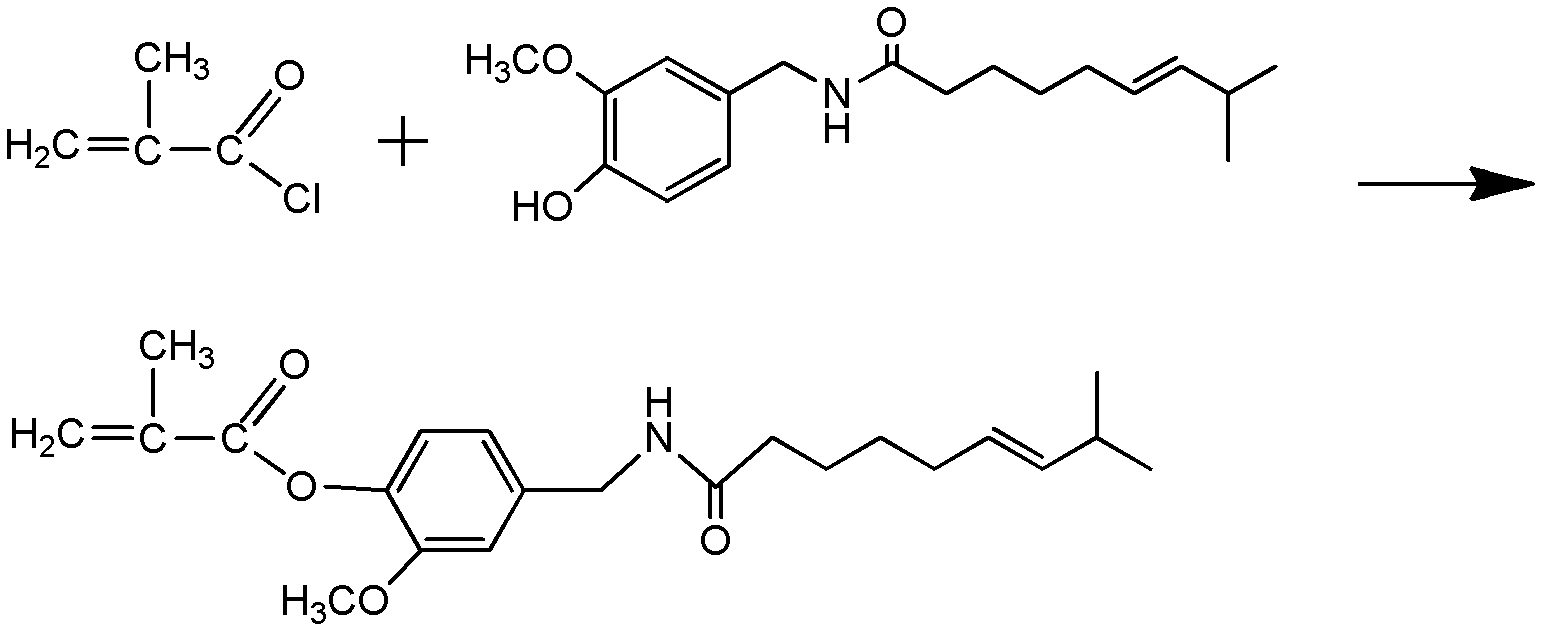

[0026] 1.5mol of capsaicin (C 18 h 27 NO 3 ) was dissolved in 500ml of anhydrous ether, and 0.2mol of basic catalyst sodium bicarbonate (NaHCO 3 ), add 1 mol of methacryloyl chloride dropwise under stirring, then reflux and stir for 8 hours, distill off methacryloyl chloride and ether under vacuum (0.1bar, 70°C), and then use a fractionating column in vacuum (0.1bar) Under fractional distillation, collect the fraction at 105~125°C to obtain capsaicin methacrylate. The preparation process is as follows: image 3 shown.

Embodiment 3

[0028] Dissolve 1.5 mol of capsaicin in 500 ml of anhydrous ether, add 0.2 mol of sodium bicarbonate powder, and add 1 mol of acryloyl chloride (C 3 h 3 OCl), then refluxed and stirred for 6 hours, distilled off acryloyl chloride and ether under vacuum (0.1bar, 70°C), then fractionated under vacuum (0.1bar) with a fractionating column, collected 95~115°C cuts, and obtained acrylic acid capsicum Vegetarian ester, the preparation process is as follows Figure 4 shown.

[0029] 2. Synthesis of polyacrylic acid-capsaicin resin

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com