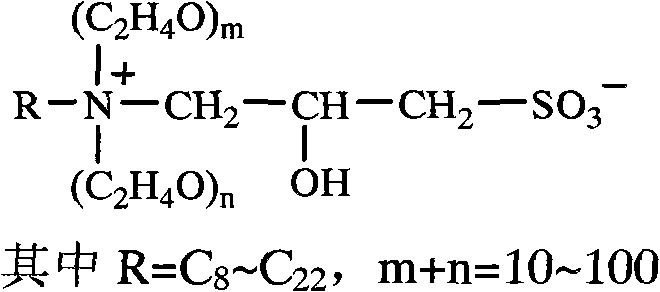

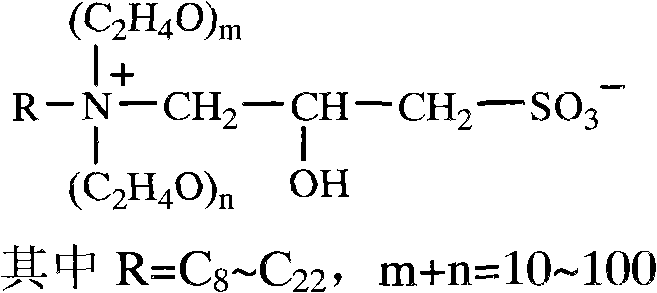

Method for preparing gydroxysulfobetaine amphoteric surface active agent including polyether chain segment

A technology of sulfobetaine and surfactants, applied in the preparation of sulfobetaine amphoteric surfactants, in the field of sulfobetaine amphoteric surfactants, can solve the problem of synergy between amphoteric/nonionic surfactants Effect, inability to improve the water solubility of hydroxysulfobetaine, troublesome synthesis of intermediates, etc., to achieve improved dispersibility, improved solubilization ability, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Preparation of 3-chloro-2-hydroxypropane sodium sulfonate: 20.8gNaHSO 3 Dissolve in water to make a saturated solution, add a phase transfer catalyst, stir and heat up to 75°C under the protection of nitrogen, start to add 18.51g of epichlorohydrin dropwise, and control the dropping time to 60min; after the dropwise addition, continue to keep warm for 0.5 h; pour out the product while it is hot, put it in an ice-water bath to cool, wait until the temperature drops below 10°C, vacuum filter, separate the solid, and dry it in an oven to obtain 3-chloro-2-hydroxypropanesulfonate sodium white powdery solid.

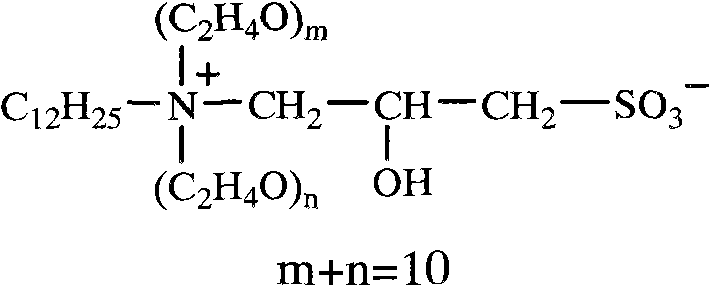

[0020] (2) Preparation of hydroxysulfobetaine amphoteric surfactant containing polyether segment: add 20.64g of 3-chloro-2-hydroxypropanesulfonate sodium prepared in a four-necked flask equipped with mechanical stirring, 62.31 g dodecylamine polyoxyethylene (10) ether, 4.15 g of 201 × 7 strong basic quaternary ammonium type I anion exchange resin, stir and heat up...

Embodiment 2

[0024] (1) Preparation of 3-chloro-2-hydroxypropane sodium sulfonate: 21.84gNaHSO 3 Dissolve in water to make a saturated solution, add a phase transfer catalyst, stir and heat up to 45°C under the protection of nitrogen, start to add 18.46g of epichlorohydrin dropwise, and control the dropwise addition time to 120min; after the dropwise addition, continue to keep warm for 5h ; Pour out the product while it is hot, put it in an ice-water bath to cool, wait until the temperature drops below 10°C, vacuum filter, separate the solid matter, and obtain 3-chloro-2-hydroxypropanesulfonate sodium white powder after drying in an oven shaped solid.

[0025] (2) Preparation of hydroxysulfobetaine amphoteric surfactant containing polyether segment: add 22.61g of prepared 3-chloro-2-hydroxypropanesulfonate sodium in a four-necked flask equipped with mechanical stirring, 106.35 g dodecylamine polyoxyethylene (20) ether, 3.87g of 4A type molecular sieve solid base, stirred and heated up to ...

Embodiment 3

[0029] (1) Preparation of sodium 3-chloro-2-hydroxypropanesulfonate: 11.44gNaHSO in a four-necked flask equipped with mechanical stirring 3 Dissolve in water to make a saturated solution, add a phase transfer catalyst, stir and heat up to 60°C under the protection of nitrogen, start to add 9.25g of epichlorohydrin dropwise, and control the dropping time to 100min; after the dropwise addition, continue to keep warm for 5h ; Pour out the product while it is hot, put it in an ice-water bath to cool, wait until the temperature drops below 10°C, vacuum filter, separate the solid matter, and obtain 3-chloro-2-hydroxypropanesulfonate sodium white powder after drying in an oven shaped solid.

[0030](2) Preparation of hydroxysulfobetaine amphoteric surfactant containing polyether segment: add 14.75 g of 3-chloro-2-hydroxypropane sulfonate sodium prepared in a four-necked flask equipped with mechanical stirring, 119.15 g dodecylamine polyoxyethylene (50) ether, 0.67 g of activated car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com