Waterborne polyurethane sand-fixing agent and preparation method thereof

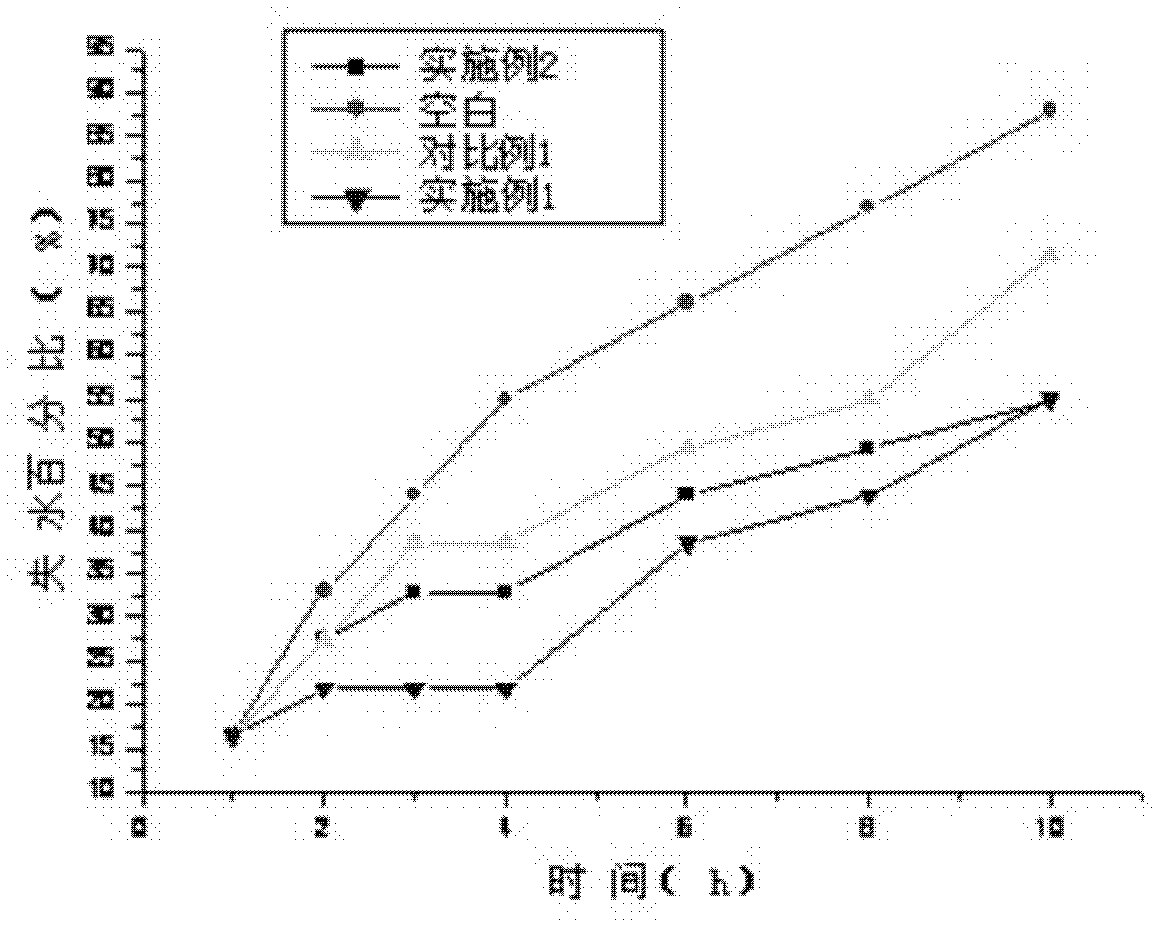

A water-based polyurethane and sand-fixing agent technology, which is applied in chemical instruments and methods, applications, organic fertilizers, etc., can solve the problems of solvent-based polyurethane, such as high toxicity, poor use safety, and environmental pollution, and achieve favorable survival and growth, water retention performance Enhanced, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]In the reactor that stirrer, thermometer, reflux condenser are equipped with, add polyoxypropylene glycol (molecular weight is 2000) 80g, 1,6-hexamethylene diisocyanate 13.5g, dimethylolpropionic acid 2.9g, heat up to 80°C, add 0.04g of dibutyltin dilaurate, and react for 4 hours under stirring to obtain a polyurethane prepolymer whose terminal groups are mainly isocyanate groups; then cool down to about 35°C, and add 0.6g of γ-aminopropyl Triethoxysilane, continue to react for 1h to obtain a prepolymer with a viscosity of 8000mPa.s, add 40g of acetone to reduce the viscosity to 3000mPa.s, and add 2.1g of potassium phosphate, 2.4g of ammonium phosphate, and 20g of deionized water. solution to neutralize the prepolymer to form a salt, then add 123 g of deionized water under high-speed shearing, and finally heat up and distill 19 g of acetone to obtain a bluish milky white water-based polyurethane dispersion. Its properties are as follows: solid content: 38.1%; PH value: 6...

Embodiment 2

[0039] In the reactor that stirrer, thermometer, reflux condenser are equipped with, add polyoxypropylene glycol (molecular weight is 2000) 70g, polyether glycol (molecular weight is 1000) 10g, toluene diisocyanate 14.6g, and prior Dissolve the solution obtained with 8g of N-methylpyrrolidone and 2.8g of dimethylolpropionic acid, stir and heat up to 70°C, and continue the reaction for 4h to obtain a polyurethane prepolymer whose terminal groups are mainly isocyanate groups; cool down to 35°C About, add 0.8g triethanolamine, react for 1h, get a prepolymer with a viscosity of 8000mPa.s, add 43g acetone to reduce the viscosity to 2400mPa.s, and add 1.1g potassium phosphate, 3.8g ammonium phosphate, 20g deionized water The formed solution neutralizes the prepolymer to form a salt, then adds 130 g of deionized water under high-speed shearing, heats up and distills 21 g of acetone to obtain a bluish milky white aqueous polyurethane dispersion. Its performance is as follows: solid co...

Embodiment 3

[0041] In the reactor that stirrer, thermometer, reflux condenser are equipped with, add polyoxypropylene glycol (molecular weight is 2000) 80g, isophorone diisocyanate 18.1g, dimethylol propionic acid 2.7g, be warming up to 80°C, add 0.03g of dibutyltin dilaurate, react for 4 hours under stirring, and obtain a polyurethane prepolymer whose terminal groups are mainly isocyanate groups; then cool down to about 35°C, add 0.6g of γ-aminopropyl three Ethoxysilane, continue to react for 1h to obtain a prepolymer, add 46g butanone to reduce the viscosity to 2400mPa.s, and add a solution consisting of 2.1g dipotassium hydrogen phosphate, 1.8g diammonium hydrogen phosphate, and 20g deionized water The prepolymer was neutralized into a salt, then 108 g of deionized water was added under high-speed shearing, and finally 25 g of methyl ethyl ketone was evaporated to obtain a bluish milky white aqueous polyurethane dispersion. Its properties are as follows: solid content: 41.5%; PH value:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com