Ultra narrow linewidth low noise high power single frequency fiber laser

A fiber laser, ultra-narrow linewidth technology, used in lasers, phonon exciters, laser parts, etc., to solve the effect of hole burning effect, not easy mode hopping phenomenon, and improve noise characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

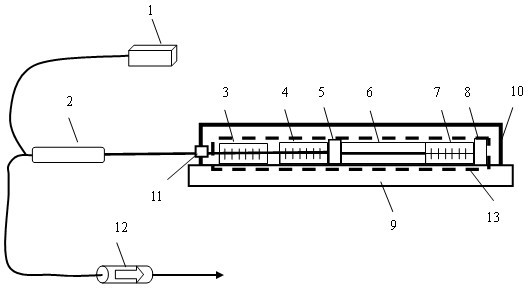

[0026] The high-gain fiber 6 is a rare-earth-doped phosphate glass single-mode fiber, which is used as the gain medium of the fiber laser. The length can be selected according to the laser output power of the device and the reflection spectrum width of the coupling output polarization-maintaining fiber grating 3. In this example, it is 1.0 cm, generally 0.5~10 cm. The high-concentration luminescent ions doped in the core of the high-gain fiber 6 are erbium and ytterbium, and the doping concentrations of erbium and ytterbium rare earth ions are 2.5×10 20 ions / cm 3 , 5.0×10 20 ions / cm 3 , generally greater than 1×10 19 ions / cm 3 . The fiber core diameter is 3-10 μm, which is 6.0 μm in this example. The core matrix composition of high-gain optical fiber 6 is phosphate glass, and its composition is: 70P 2 o 5 -8Al 2 o 3 -15BaO-4La 2 o 3 -3Nd 2 o 3 . Rare earth ions are uniformly doped at a high concentration in its core. High-gain optical fiber 6 is made of preform...

Embodiment 2

[0030] The high-gain fiber 6 is a rare-earth-doped phosphate glass single-mode polarization-maintaining fiber, which is used as the gain medium of the fiber laser. The length can be selected according to the laser output power of the device and the reflection spectrum width of the coupled output polarization-maintaining fiber grating 3. In this example 1.0cm, generally 0.5~10cm. The uniformly doped high-concentration luminescent ion of the high-gain fiber 6 core is ytterbium, and the doping concentration of ytterbium ions is 7.5×10 20 ions / cm 3 , generally greater than 1×10 19 ions / cm 3 . The core diameter of the high-gain fiber 6 is 8 μm, generally 1-10 μm. The polarization characteristics of the panda-eye structure are designed. The two panda eyes are arranged symmetrically and have the same size. The warp size is 16 μm, generally 10-20 μm is acceptable, and the cladding diameter is 125 μm, generally 125-400 μm is acceptable. The core matrix composition of high-gain opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com