Method for preparing LiFePO4/C composite cathode material by continuous reaction

A composite cathode material, lithium hydroxide technology, applied in nanotechnology for materials and surface science, chemical instruments and methods, phosphorus compounds, etc., can solve the general requirements of difficult material uniformity, low tap density, specific capacity low problems, to achieve the effect of good electrochemical performance, high tap density and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

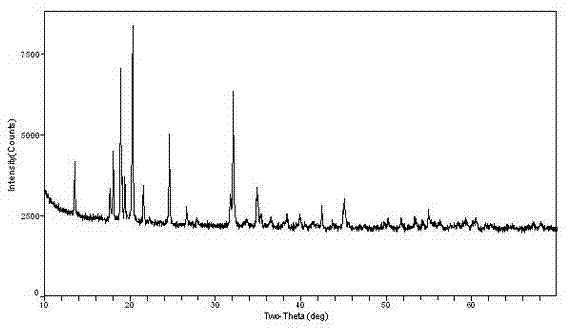

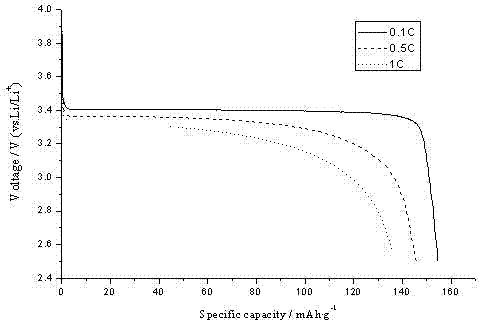

[0021] Embodiment 1: A kind of continuous reaction prepares LiFePO 4 The method of / C composite positive electrode material is characterized in that: with iron filings, nitric acid, phosphoric acid, lithium hydroxide as raw material, carry out according to the following steps: first use 600 milliliters of 4.0 mol / liter dilute nitric acid solution (containing 2.4 moles of nitric acid) and 33.6 gram of iron filings (converted from the atomic weight of iron to 56 grams / mole to obtain 0.6 moles of iron) to react (the molar ratio of iron filings to dilute nitric acid is 1:4) to prepare ferric nitrate solution, and pass the hot reaction liquid through a filter Put into another reaction tank, then add 69 grams of 85% commercially available phosphoric acid in the reaction tank, under vigorous stirring, use the heating mantle to heat and reflux to react, lithium hydroxide, ferric phosphate dihydrate and carbon source are first wet Lithium ferrous phosphate double salt can be prepared b...

Embodiment 2

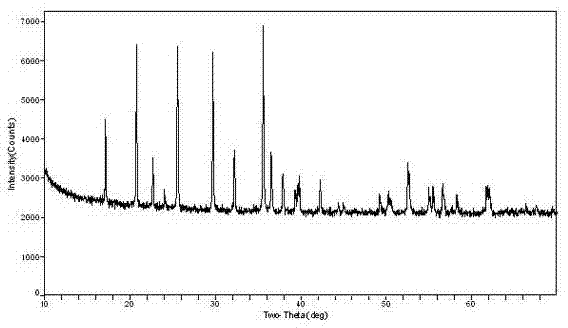

[0035] Embodiment 2: A kind of continuous reaction prepares LiFePO 4 The method of / C composite positive electrode material is characterized in that: with iron filings, nitric acid, phosphoric acid, lithium hydroxide as raw material, carry out according to the following steps: first use 600 milliliters of 3.0 mol / liter dilute nitric acid solution (containing 1.8 moles of nitric acid) and 25.2 gram of iron filings (converted from the atomic weight of iron of 56 g / mol to 0.45 moles of iron) to react (the molar ratio of iron filings to dilute nitric acid is 1:4) to prepare ferric nitrate solution, and pass the hot reaction solution through a filter Put into another reaction tank, then add 51.8 grams of 85% commercially available phosphoric acid in the reaction tank, under vigorous stirring, use the heating mantle to heat and reflux to react, lithium hydroxide, ferric phosphate dihydrate and carbon source are first wet Lithium ferrous phosphate double salt can be prepared by mixin...

Embodiment 3

[0049] Embodiment 3: A kind of continuous reaction prepares LiFePO 4 / C composite cathode material method, characterized in that: iron filings, nitric acid, phosphoric acid, lithium hydroxide as raw materials, according to the following steps: first use 600 milliliters of 2.0 mol / liter dilute nitric acid solution (containing 1.2 moles of nitric acid) and 16.8 gram of iron filings (converted from the atomic weight of iron to 56 grams / mole to obtain 0.3 moles of iron) to react (the molar ratio of iron filings to dilute nitric acid is 1:4) to prepare ferric nitrate solution, and pass the hot reaction liquid through a filter Put into another reaction tank, then add 34.6 grams of 85% commercially available phosphoric acid in the reaction tank, under vigorous stirring, use the heating mantle to heat and reflux to react, first wet lithium hydroxide, ferric phosphate dihydrate and carbon source Mixing materials by high-temperature carbon reduction to produce lithium iron phosphate dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com