Preparation method for 1-chlorine-1,1-difluoroethane

A technology for difluoroethane and acetylene, which is applied in the field of preparing 1-chloro-1 from acetylene, can solve the problems of high production cost, many by-products, increased cost, etc., and achieves small footprint, less by-products, and material back-mixing. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The acetylene gas and HF gas enter the vaporizer to be vaporized according to the volume ratio of 1:6, then enter the preheating device, and then pass into the fixed bed reactor, under the action of catalyst I, the mixture of chromium chloride, palladium chloride and activated carbon (the quality of chromium chloride is 15% of the total mass of catalyst 1, palladium chloride is 4% of the total mass of catalyst 1, and all the other are gacs). The contact time in the fixed-bed reactor is 6s, and the reactor pressure is 0.5MPa. The reaction product is washed with water and alkali, then passed through the degassing device, enters the rectification tower for rectification, and finally passes through the drying device, and samples are taken from the outlet of the reactor for analysis. , acetylene conversion and 1,1-difluoroethane selectivity are listed in Table 1.

Embodiment 2、3、4

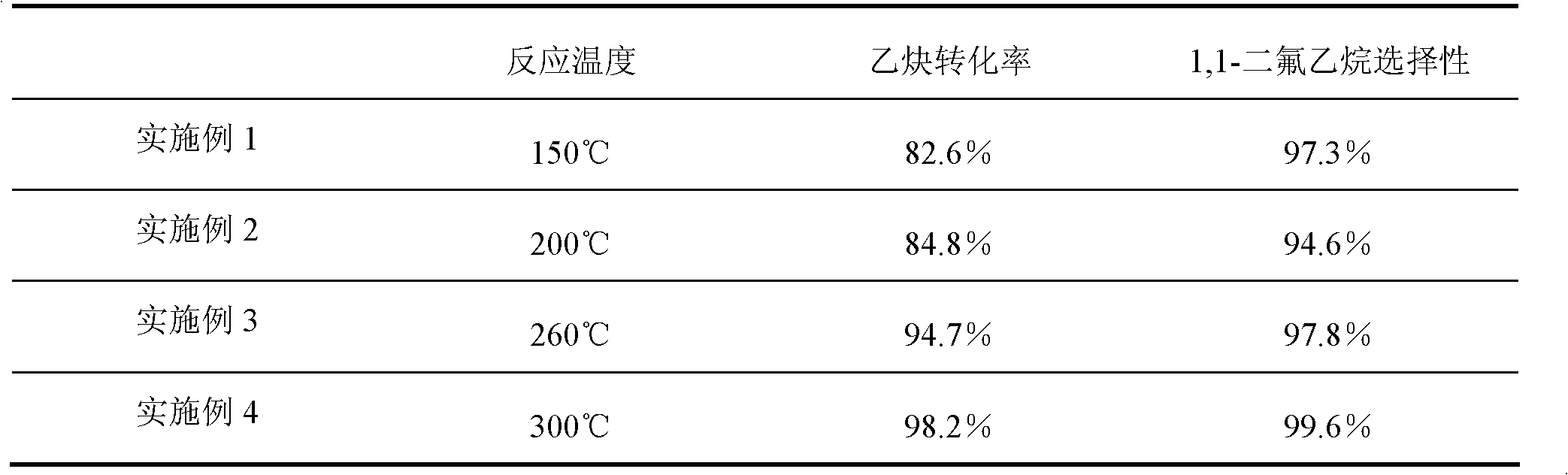

[0052] Embodiment 2,3,4: single reaction condition contrast

[0053] The reaction conditions are in accordance with the operation steps described in Example 1, keeping other reaction conditions unchanged, respectively controlling the reaction temperature to 200°C, 260°C, and 300°C, and analyzing the samples from the outlet of the reactor, the acetylene conversion rate and 1,1- Difluoroethane selectivity is listed in Table 1.

[0054] Table 1

[0055]

Embodiment 5、6、7、8

[0056] Embodiment 5,6,7,8 reaction contrast:

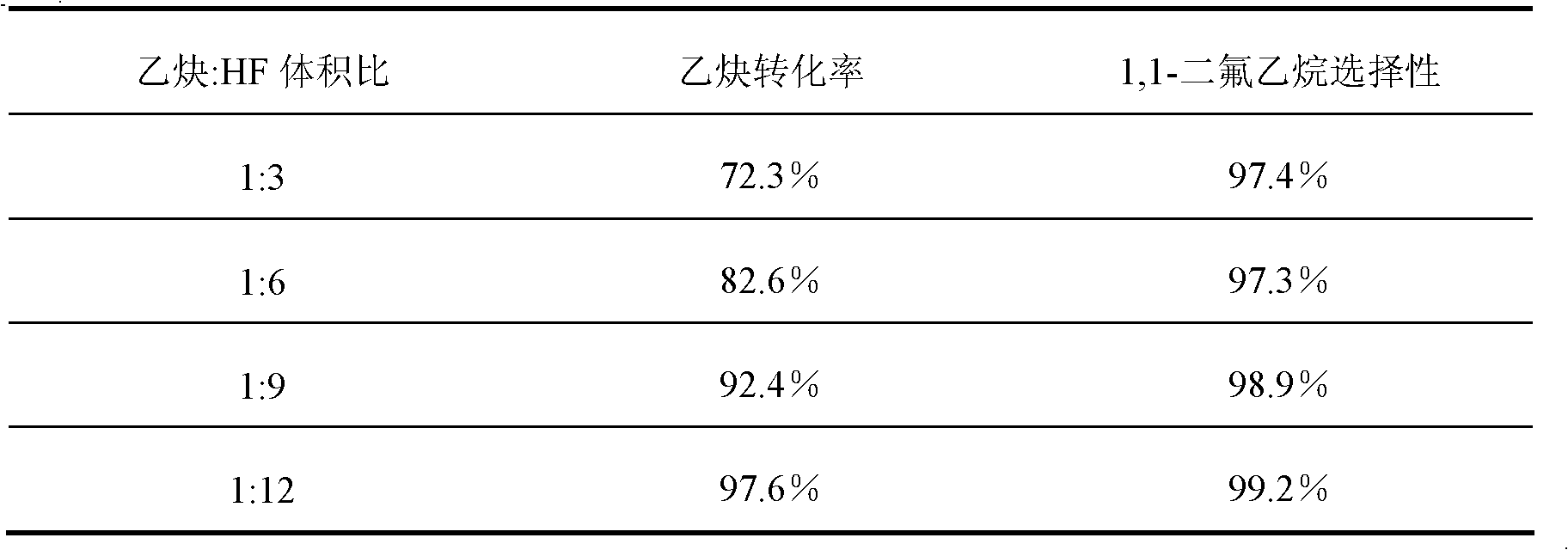

[0057] Reaction conditions are according to the operating procedure described in embodiment 1, keep other reaction conditions constant, control reaction material feed ratio respectively, control acetylene and HF feed volume ratio to be respectively 1: 3, 1: 6, 1: 9, 1:12 samples were analyzed at the outlet of the reactor, and the conversion rate of acetylene and the selectivity of 1,1-difluoroethane are listed in Table 2.

[0058] Table 2

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com