Wet separation technology for material containing lead, bismuth and molybdenum

A wet separation and material technology, applied in the direction of improving process efficiency, can solve the problems of complicated process, large loss of molybdenum, affecting the recovery rate of lead, bismuth and molybdenum, and purification of metal products, and achieves high metal recovery rate and high added value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

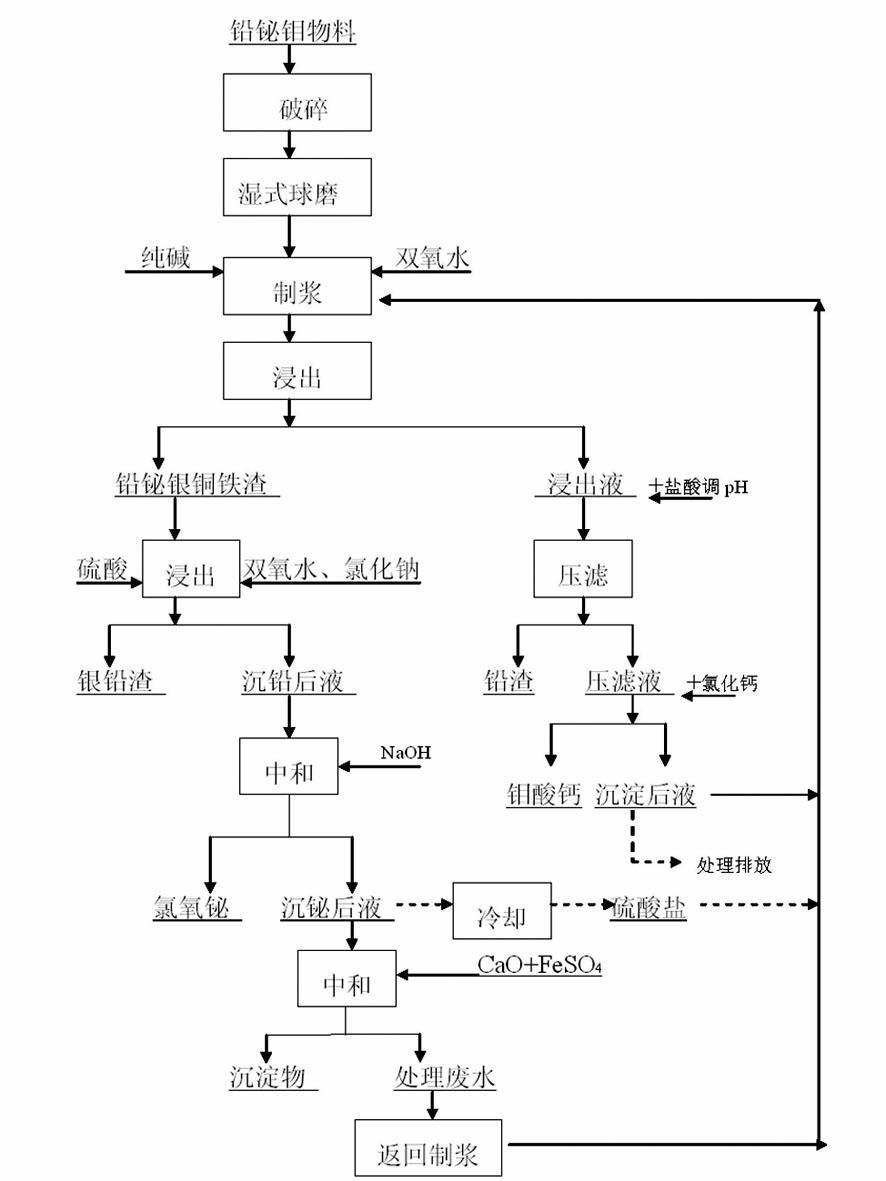

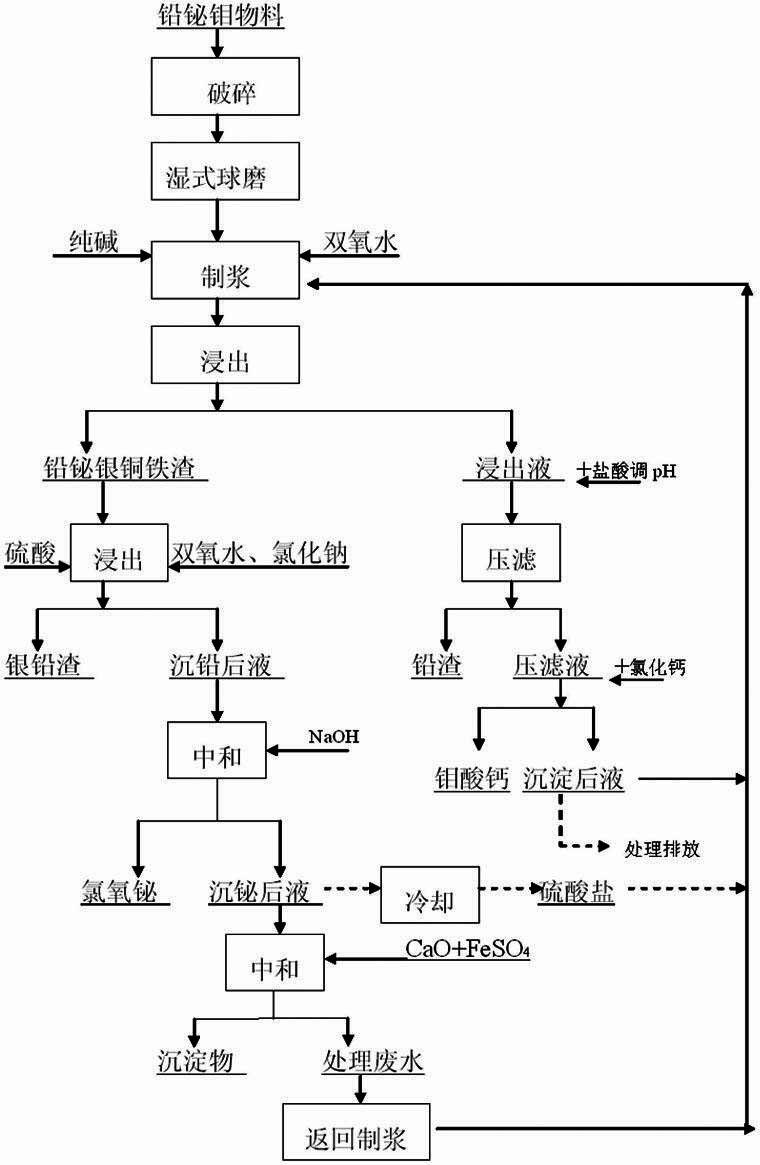

[0024] Describe the present invention below in conjunction with the specific embodiment of accompanying drawing;

[0025] The bismuth-containing material that present embodiment adopts, concrete composition is as follows:

[0026] Pb: 35.81%, Bi: 13.08%, Mu: 10.58%, S: 0.8%, Ag: 0.53%, Fe: 1.5%, Cu: 0.58%;

[0027] The material is made of refinery waste slag in lumps, and has a metallic luster after cracking. Bismuth and molybdenum are of high value in the material, and the others are recovered from by-products.

[0028] The process steps of wet separation of valuable metals from the above lead-containing bismuth and molybdenum materials are shown in the accompanying drawings.

[0029] a. Crushing large pieces of lead-containing, bismuth and molybdenum materials until the particle diameter is less than 3cm;

[0030] b The cracked material is ball milled by a wet ball mill to control more than 85%, or 100% of the material particle size can reach -100;

[0031] c Wet-type bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com