Method for extracting cobalt and copper from cobalt-copper-iron alloy

A technology of cobalt-copper-iron alloy and alloy, which is applied in the field of extracting cobalt and copper from cobalt-copper-iron alloy, can solve the problems of decreased leaching effect, high equipment requirements, and increased acid consumption, so as to reduce the difficulty of filtration and washing, reduce the difficulty of processing, and reduce the acid the effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A company's high-silicon cobalt copper-iron alloy in the Congo is composed of Co 38.6%, Fe 38.4%, Cu 15.4%, Si 9.45%

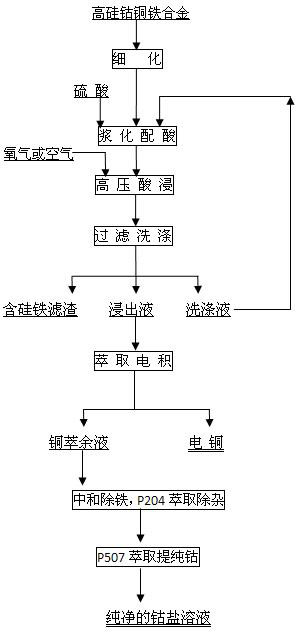

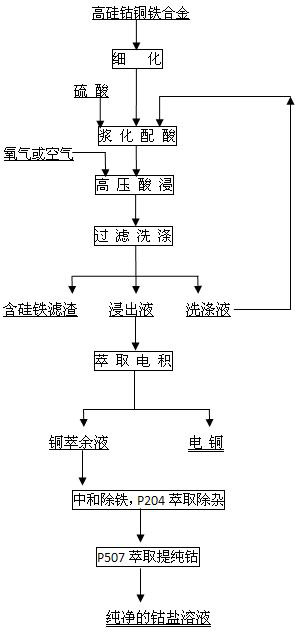

[0069] (1) Press figure 1 The alloy is refined to 99% less than 74μm by Raymond mill coarse grinding-ball mill fine grinding.

[0070] (2) The pressure leaching conditions are as follows: the liquid-solid weight ratio of the pulp is 15:1, the initial sulfuric acid concentration is 70g / L, the leaching temperature is 135°C, the oxidant is industrial pure oxygen, the total leaching pressure is 0.45MPa, and the oxygen partial pressure Control at 0.2Mpa, leaching time is 3h. The leaching rates of copper and cobalt were 99.3% and 99.8%, respectively, the leaching rate of iron was only 2.45%, and silicon was not leached.

[0071] (3) The leaching pulp is filtered to obtain leachate and leaching slag. The leaching slag is washed by three-stage countercurrent pulping. The washing water is 5 times the amount of slag, and the washing water is returned to leachin...

Embodiment 2

[0074] A company imported high-silicon cobalt copper-iron alloy from Congo, the composition of which is Co 31.76%, Fe 30.82%, Cu 25.81%, Si 13.12%.

[0075] (1) Press figure 1 The alloy is refined to 99% less than 74μm by Raymond mill coarse grinding-ball mill fine grinding.

[0076] (2) The pressure leaching conditions are as follows: the liquid-solid weight ratio of the pulp is 5:1, the initial sulfuric acid concentration is 230g / L, the leaching temperature is 170°C, the oxidant is industrial pure oxygen, the total pressure of leaching is 0.9MPa, and the oxygen partial pressure Controlled at 0.2MPa, leaching time is 1h. The leaching slag rate was 76.15%, the leaching rates of copper and cobalt were 99.8% and 99.9% respectively, the leaching rate of iron was only 0.85%, and silicon was not leached.

[0077] (3) The leaching pulp is filtered to obtain leachate and leaching slag. The leaching slag is washed by three-stage countercurrent pulping. The washing water is 6 times t...

Embodiment 3

[0080] The high-silicon-cobalt copper-iron alloy imported from the Congo by a company has a composition of 38.6% Co, 38.4% Fe, 15.4% Cu, and 9.45% Si.

[0081] (1) Press figure 1 The alloy is refined to 99% less than 74μm by Raymond mill coarse grinding-ball mill fine grinding.

[0082] (2) The pressure leaching conditions are as follows: the liquid-solid weight ratio of the pulp is 10:1, the initial sulfuric acid concentration is 120g / L, the leaching temperature is 150°C, the oxidant is industrial pure oxygen, the total pressure of leaching is 0.6MPa, and the oxygen partial pressure Control at 0.2Mpa, leaching time is 3h. The leaching rates of copper and cobalt were 98.9% and 99.5%, respectively, the leaching rate of iron was only 1.05%, and silicon was not leached.

[0083] (3) The leaching pulp is filtered to obtain leachate and leaching slag. The leaching slag is washed by three-stage countercurrent pulping. The washing water is 5 times the amount of slag, and the washin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com