Method for measuring content of ferrous iron and ferric iron in ferrous phosphate lithium anode material

A technology that applies lithium iron phosphate and cathode materials in the measurement of color/spectral characteristics, etc., can solve problems such as affecting the environment, chromium pollution, mercury pollution, etc., and achieve accurate results, accurate and reliable results, and high sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Determination of ferrous iron content (o-phenanthroline spectrophotometry)

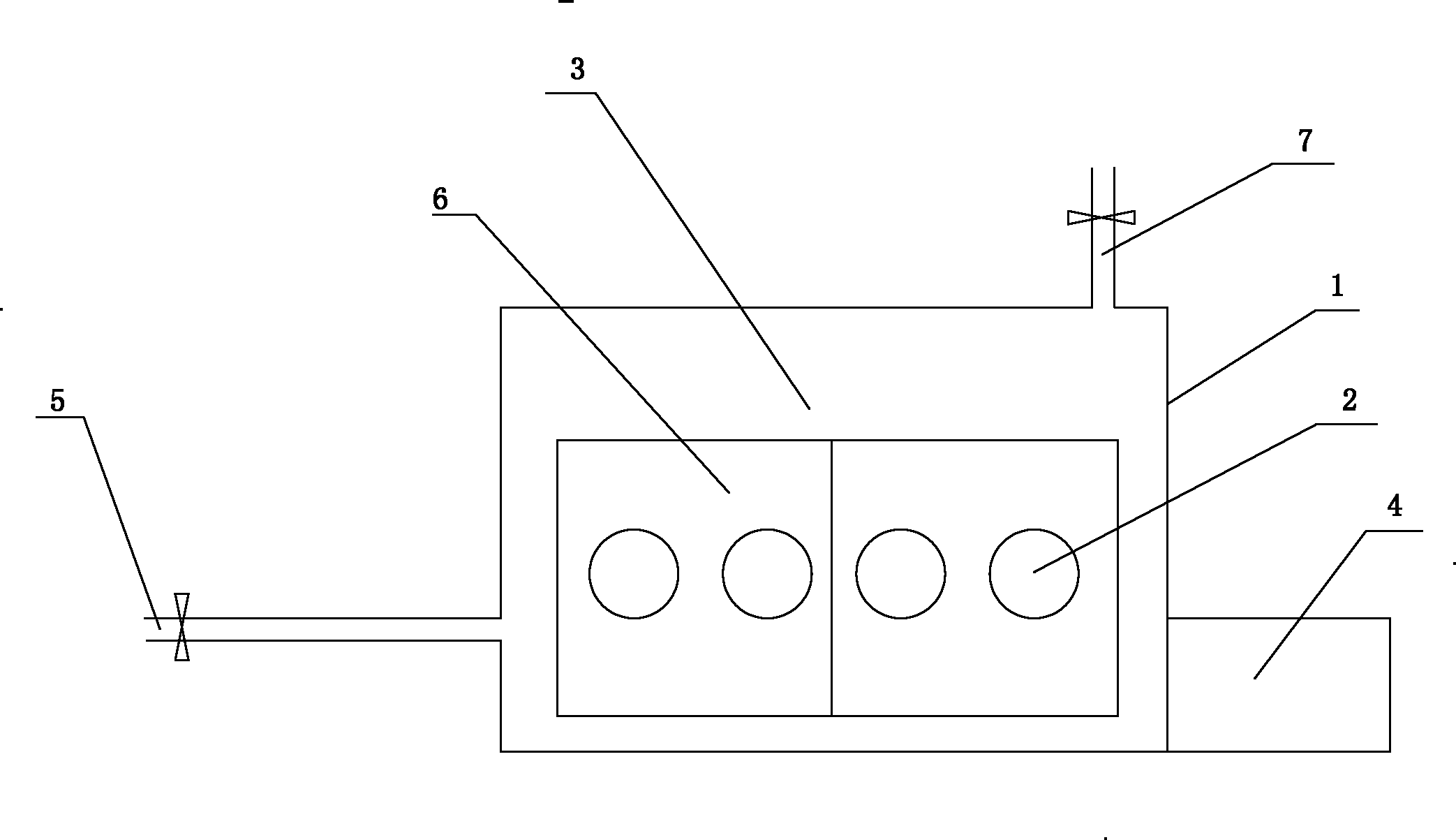

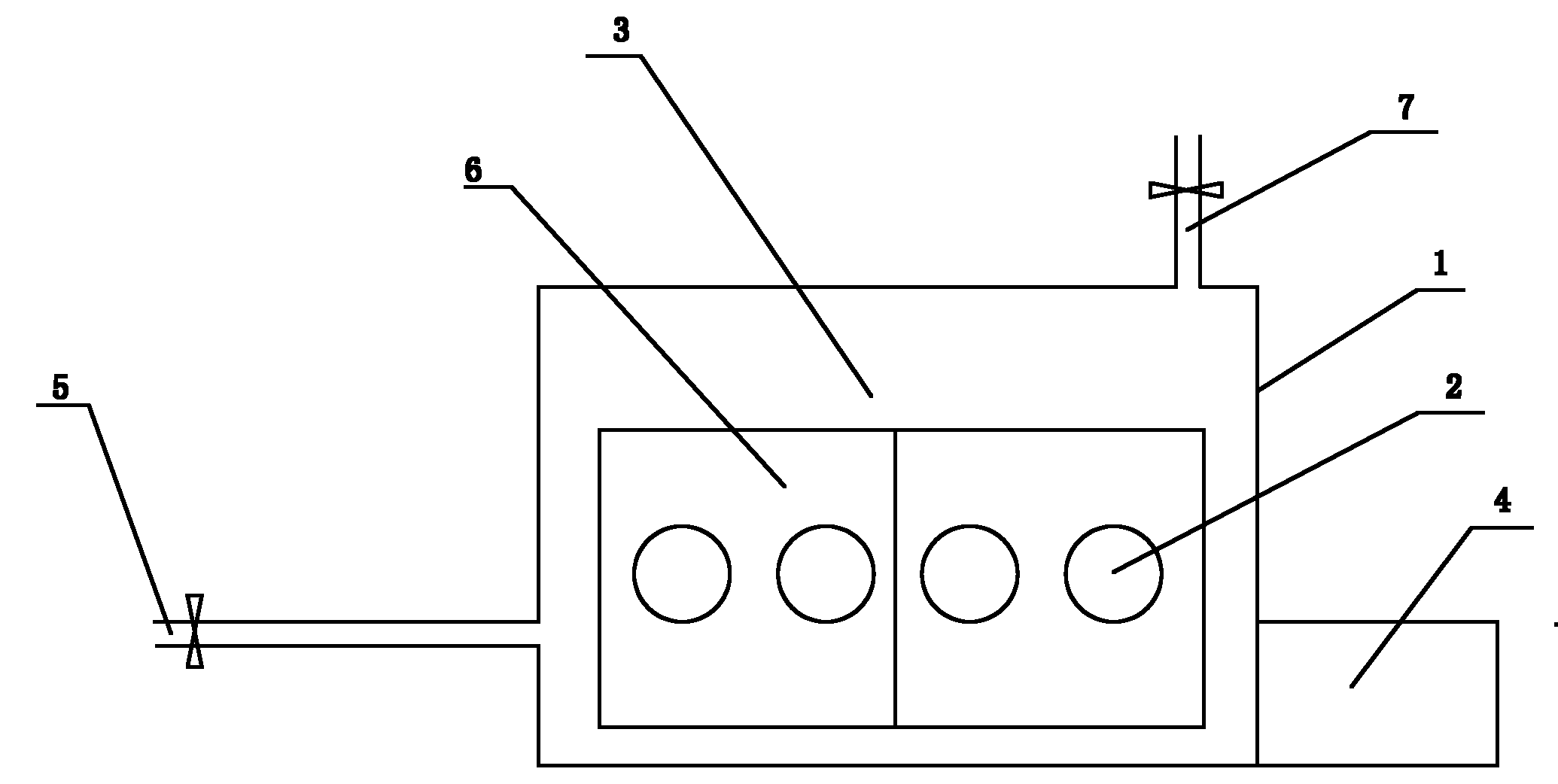

[0032] Carry out following experimental test in the protective atmosphere device of the present invention that has provided argon protective atmosphere:

[0033] 1.1 Preparation of ferrous solution:

[0034] Step 1: Weigh LiFePO 4 Put 0.5000 g of the sample in a beaker, rinse the wall of the beaker with a small amount of water, add 40 ml of hydrochloric acid (1:1), cover with a watch glass, and place it on a low-temperature electric furnace to heat to a slight boil. After keeping for 20 min, remove and cool to room temperature, filter, transfer the filtrate into a 100 ml volumetric flask and add water to volume.

[0035] Step 2: According to the expected iron content in the sample, add 1.0 ml of the solution obtained in the first step above to a 1000 ml volumetric flask.

[0036] Step 3: Dilute to 60 ml with water, adjust the pH to 3 with hydrochloric acid solution (detected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com