Method for isolating compound metal grid from back electrode during large-area preparation of dye sensitized solar cell (DSSC)

A composite metal and metal mesh technology, applied in the field of solar photovoltaic utilization, can solve the problems of DSSC not working normally, short circuit, hindering the realization of DSSC industrialization, etc., to reduce internal resistance, avoid internal short circuit, and increase output power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

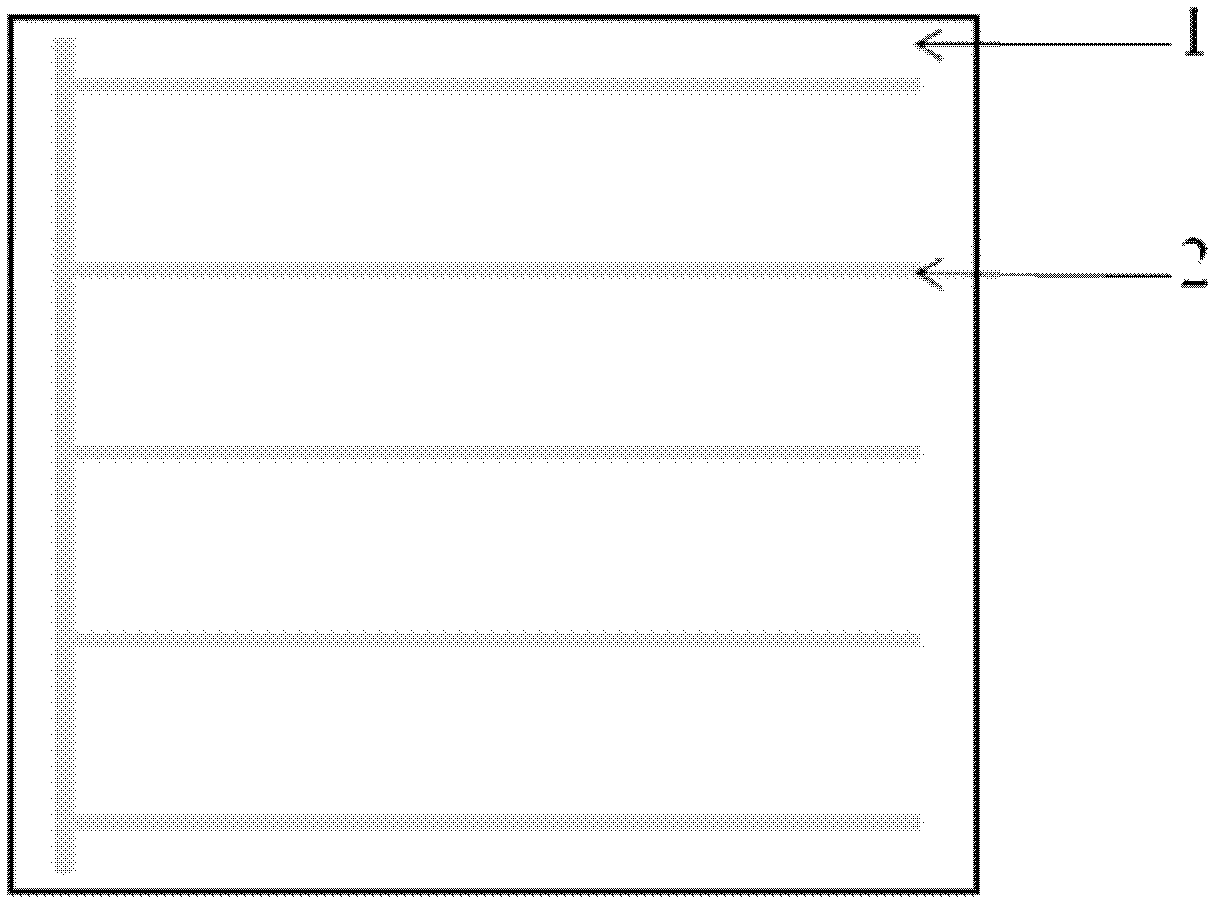

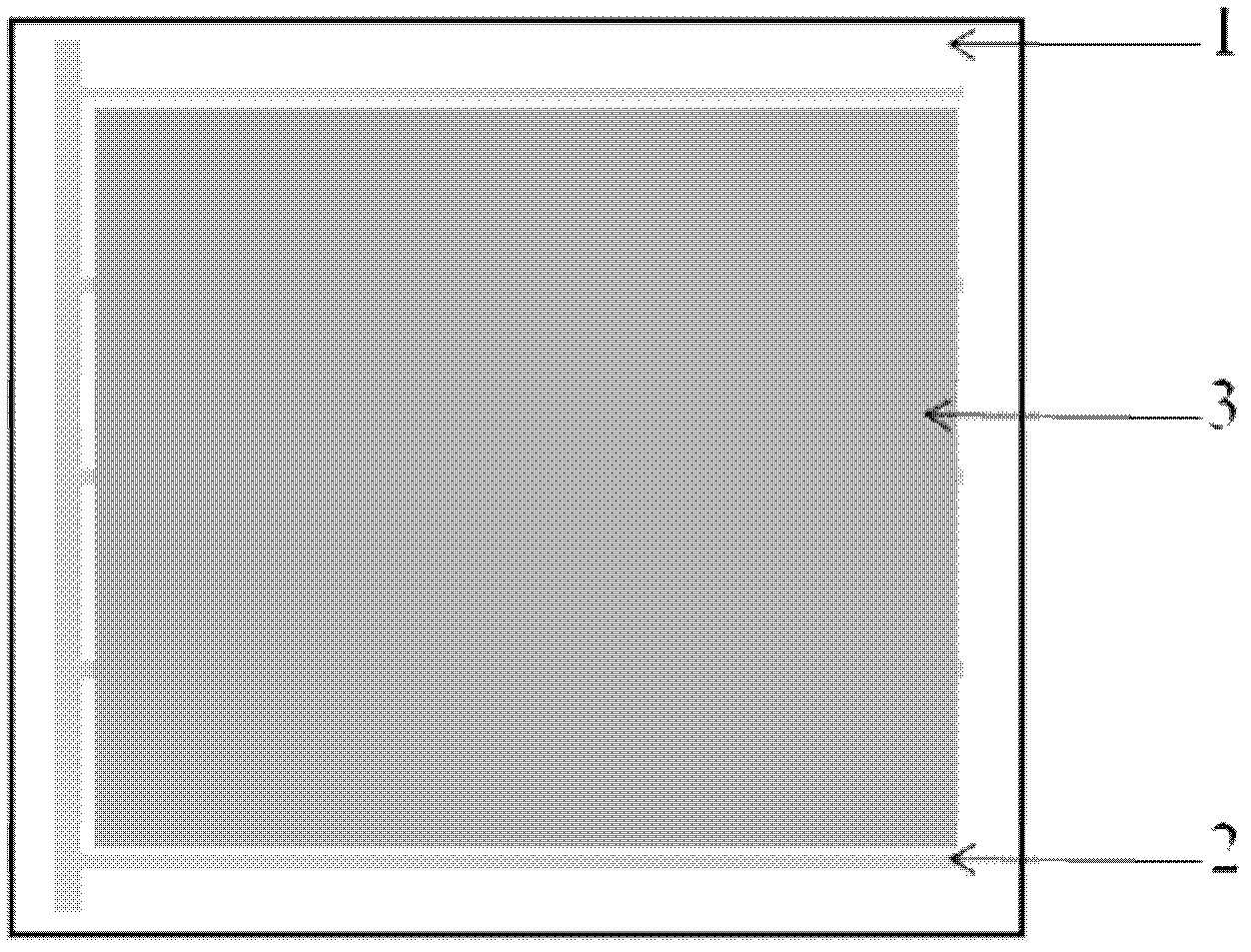

[0057] Isolation of Composite Metal Grid and Back Electrode

[0058] The transparent conductive substrate is made of FTO (F-doped tin oxide) conductive glass from Nippon Sheet Glass Company of Japan, and the substrate is placed in an ultrasonic water bath cleaning machine for cleaning and drying for the next step of the preparation process.

[0059] First prepare the TiO needed for screen printing 2 Slurry, concrete preparation steps are as follows:

[0060] 1) In 5 grams of TiO 2 The powder (manufactured by Degussa, Germany) was mixed with 1 ml of deionized water and 1 ml of glacial acetic acid and mixed for 10 minutes to obtain slurry A. Then slowly add 80ml of ethanol to the slurry A, and keep grinding the mixed solution when adding, and then continue grinding for about 10 minutes to make the slurry B;

[0061] 2) Transfer slurry B to a stirrer and stir for 60 minutes at a rotating speed of 2000r / min, add 15ml sesame oil brain, and continue stirring for 60min at a rotati...

Embodiment 2

[0072] Isolation of Composite Metal Grid and Back Electrode

[0073] The transparent conductive substrate adopts FTO (F-doped tin oxide) conductive glass from Nippon Sheet Glass Company of Japan, and the substrate is placed in an ultrasonic water bath cleaning machine for cleaning and drying.

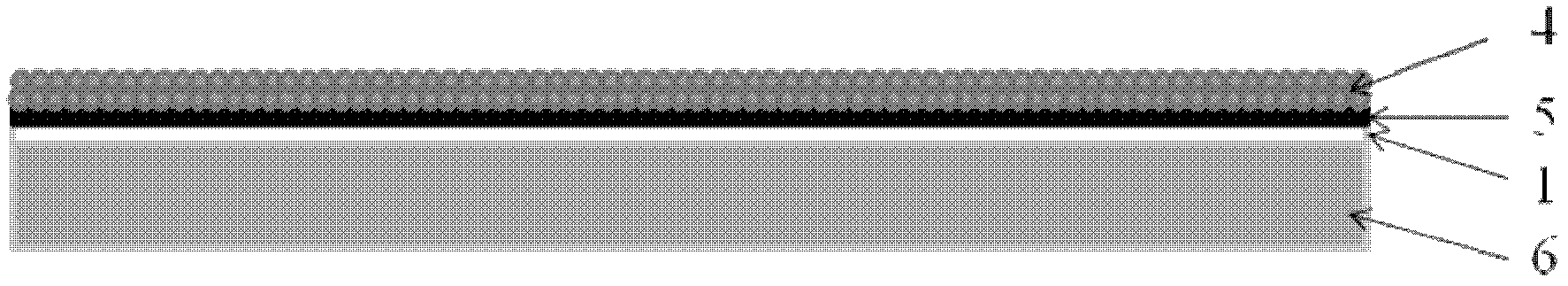

[0074] According to the method preparation TIO of embodiment 1 2 After the paste, the composite metal grid is sputtered on the FTO conductive glass, first sputtering metal Al with a thickness of 80nm as the first layer; then sputtering metal Ti with a thickness of 55nm.

[0075] In the next step, TiO was screen-printed on the FTO conductive glass substrate. 2 Film preparation. The parameters of the screen are: mesh number 300, wire diameter 40 μm, pore diameter 45 μm, and opening ratio 28%. Firstly, the prepared TiO 2 The paste is printed on a glass substrate.

[0076] In the next step, the substrate printed with the paste was heated at 500°C for 2 hours, so that the TiO 2 The org...

Embodiment 3

[0080] Isolation of Composite Metal Grid and Back Electrode

[0081] The transparent conductive substrate adopts FTO (F-doped tin oxide) conductive glass from Nippon Sheet Glass Company of Japan, and the substrate is placed in an ultrasonic water bath cleaning machine for cleaning and drying.

[0082] According to the method preparation TIO of embodiment 1 2 After the paste, the composite metal grid is sputtered on the FTO conductive glass, first sputtering metal Al with a thickness of 200nm as the first layer; then sputtering metal Ti with a thickness of 145nm.

[0083] In the next step, TiO was screen-printed on the FTO conductive glass substrate. 2 Film preparation. The parameters of the screen are: mesh number 300, wire diameter 40 μm, pore diameter 45 μm, and opening ratio 28%. Firstly, the prepared TiO 2 The paste is printed on a glass substrate.

[0084] In the next step, the substrate printed with the paste was heated at 500°C for 2 hours, so that the TiO 2 The o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com