Method for preparing ZnO nano-array composite system modified by gold nanoparticles

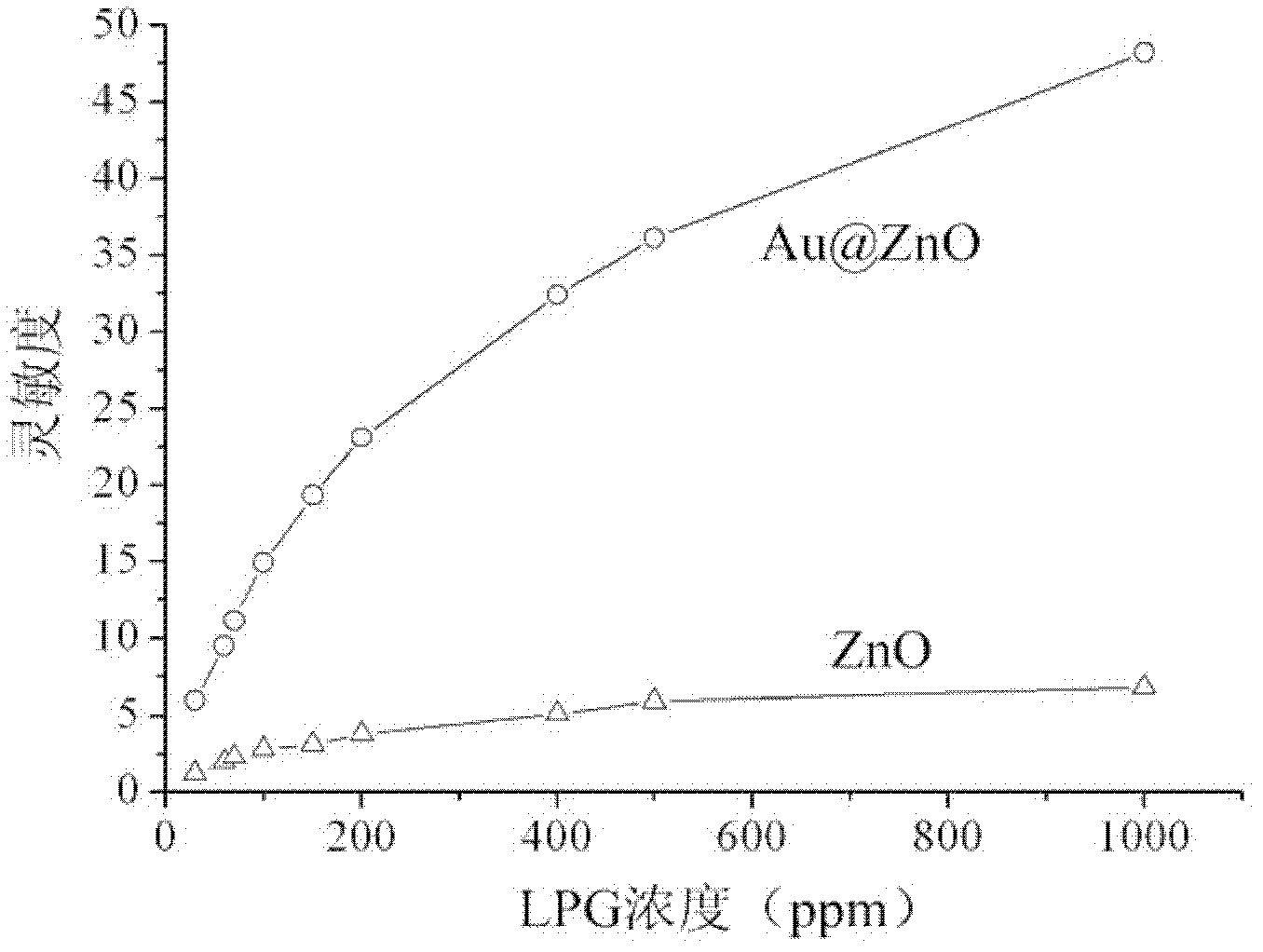

A technology of zinc oxide nanoparticles and gold particles, which is applied in the process of producing decorative surface effects, decorative arts, gaseous chemical plating, etc., can solve the problems of unsatisfactory sensitivity and selectivity, long response time, and high working temperature , to achieve the effect of good sensitivity and selectivity, wide detection range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] A method for preparing a gold particle-modified zinc oxide nano-array composite system, based on the preparation of ZnO nano-sol, through pulling film formation and heat treatment, forming a ZnO nano-particle film in situ on an alumina ceramic tube or a silicon substrate, Then use the nanoparticle film as the seed crystal to epitaxially grow ZnO nanorods in the solution, and then obtain ZnO nanoarrays decorated with nanoscale gold particles by vacuum evaporation. The steps are as follows:

[0021] 1) Add 5.49g zinc acetate Zn(CH 3 COO) 2 2H 2 O was mixed with 250 ml of absolute ethanol, heated at a constant temperature of 90°C under reflux to pre-hydrolyze into Zn 10 o 4 (Ac) 12 , adding 1.5g hydrated lithium hydroxide to continue the hydrolysis reaction, and after magnetic stirring for 2 hours, a colorless and clear zinc oxide sol was obtained;

[0022] 2) Put the alumina ceramic tube into the ZnO sol, grow the ZnO sol protopically on the alumina ceramic tube by p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com