Polysilicon ingot casting method with low defect and high output and thermal field structure thereof

A polysilicon, low-defect technology, applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of high grain boundary and dislocation defect density, low solar cell efficiency, and insignificant cost advantages. Improve crystal quality, reduce energy consumption, and facilitate the effect of adjusting the crystal growth interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

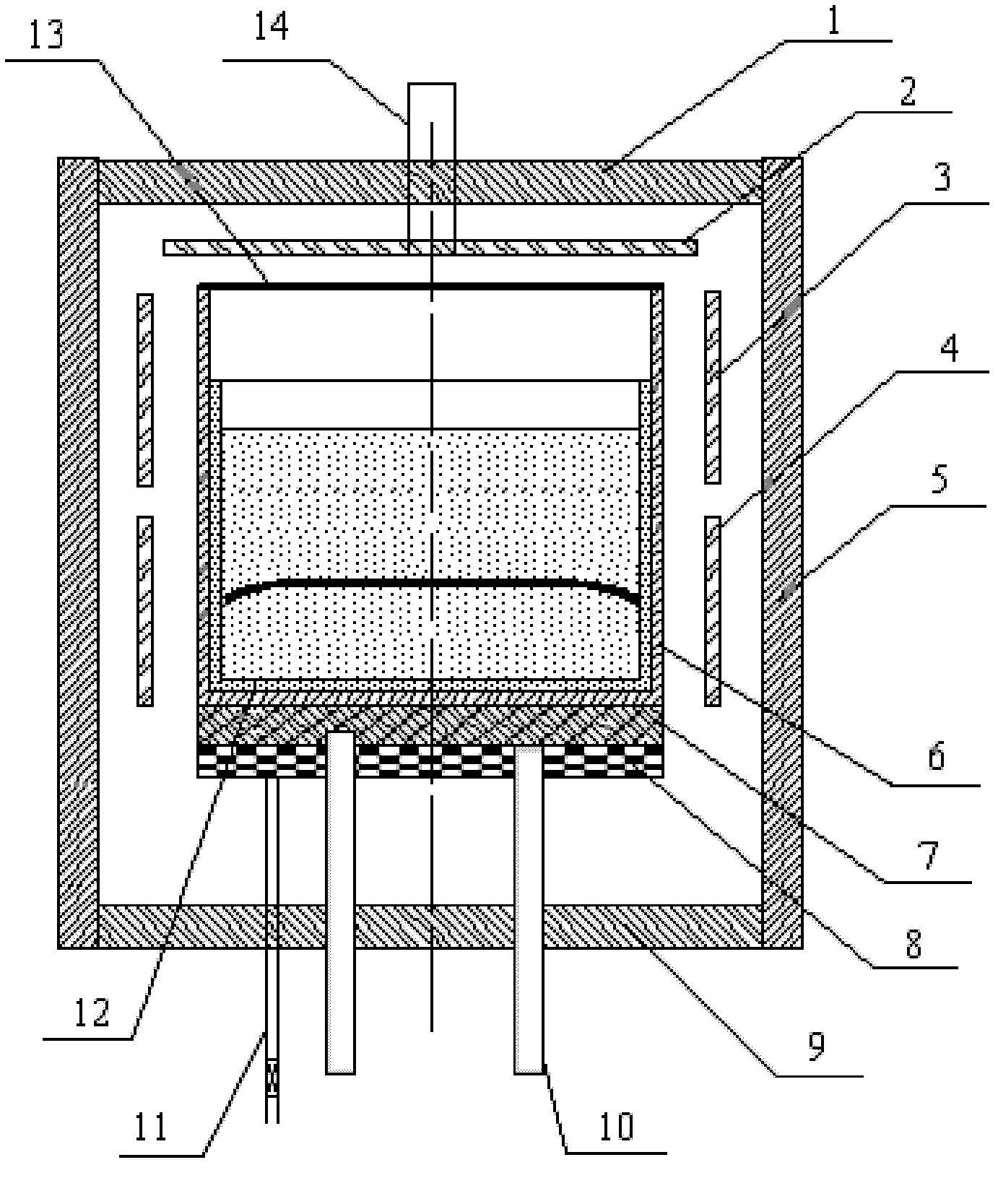

[0025] After the quartz crucible 12 is filled with 650kg of silicon material, the outsourcing graphite crucible 6 is placed on the support block 7, the side wall 5 of the insulation cover and the lower insulation plate 9 are closed, and the distance between the top heater 2 and the support block 7 reaches 650mm. The furnace body is evacuated, and after the vacuum degree required by the process is reached, the top heater 2, the side heater 3 and the side heater 4 start to work. After initial preheating, the inert protective gas argon is gradually introduced through the protective gas introduction pipe 14, The pressure in the furnace is maintained at 0.5 atm. Due to the heat preservation effect of the heat preservation cover, the temperature in the heat preservation cover can be raised to a high temperature of about 1500°C, so that the silicon material can be heated and melted within more than ten hours. The argon gas that circulates during the materialization can carry the impur...

Embodiment 2

[0030] After the quartz crucible 12 is filled with 750kg of silicon material, the outsourcing graphite crucible 6 is placed on the support block 7, the side wall of the heat preservation cover 5 and the lower insulation plate 9 are closed, and the distance between the top heater 2 and the support block 7 reaches 700mm. The furnace body is evacuated, and after the vacuum degree required by the process is reached, the top heater 2, the side heater 3 and the side heater 4 start to work. After initial preheating, the inert protective gas argon is gradually introduced through the protective gas introduction pipe 14, The pressure in the furnace is maintained at 0.6atm. Due to the heat preservation effect of the heat preservation cover, the temperature in the heat preservation cover can be raised to a high temperature of about 1500°C, so that the silicon material can be heated and melted within more than ten hours. The argon gas that circulates during the materialization can carry the...

Embodiment 3

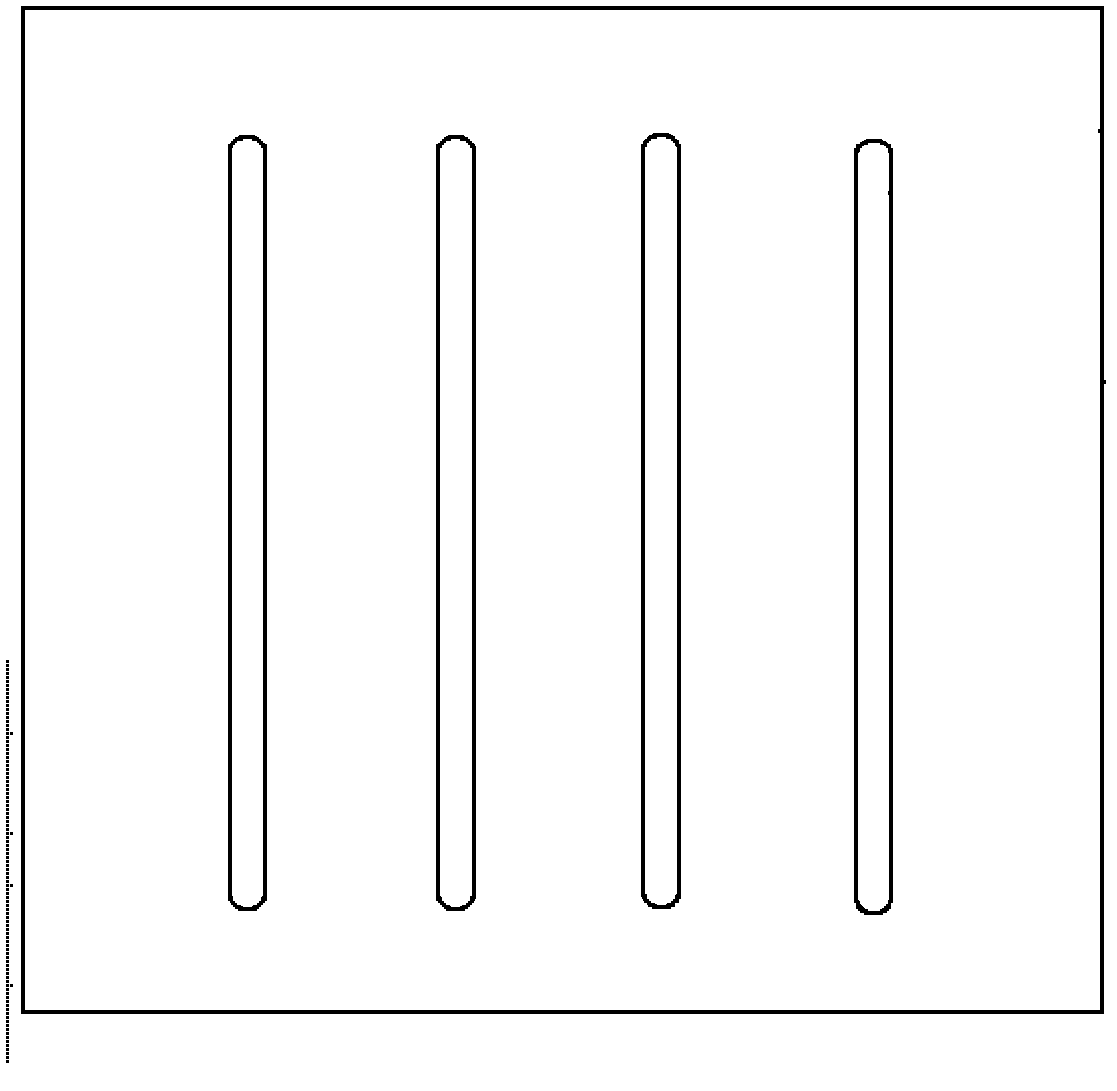

[0035] Quartz crucible 12 first lays a strip-shaped crystal-oriented single crystal with a certain thickness at the position corresponding to the cooling point of the support block at the bottom of the crucible, and then fills it with 650kg of silicon material, outsources the graphite crucible 6, and places it on the support block 7, and the support block 7 With 4 strip cooling spots, such as image 3 , the insulation cover side wall 5 and the lower insulation board 9 are closed, the distance between the top heater 2 and the support block 7 reaches 650mm, the furnace body is evacuated, and after reaching the vacuum degree required by the process, the top heater 2 and the side heater 3 and side lower heater 4 start to work, and after the initial preheating, the inert protective gas argon is gradually introduced through the protective gas introduction pipe 14 to maintain the pressure in the furnace at 0.4 atm. After rising to a high temperature of 1400°C, lift the heat preserva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com