Structure of surface mount device micro electromechanical oscillator and manufacturing method thereof

An electric oscillator and surface-attached technology, which is applied to the structure of a surface-attached micro-electromechanical oscillator and its manufacturing field, can solve the problems of increasing manufacturing costs, stopping vibration, and consuming large amounts of power, thereby reducing production costs, improving production efficiency, The effect of reducing equipment expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

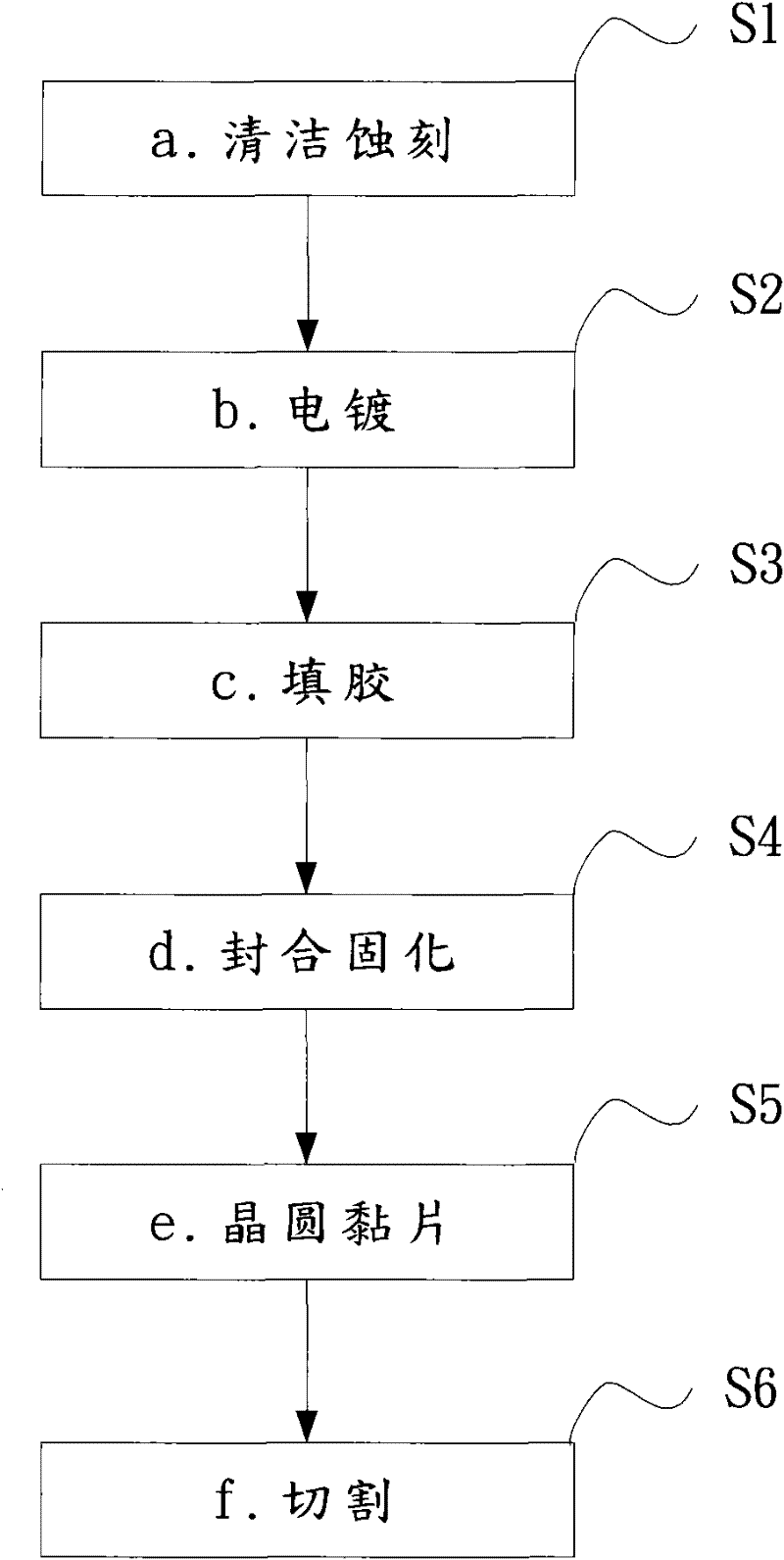

[0053] see figure 1 , figure 1 It is a flow chart of the manufacturing method of the surface-mounted micro-electro-mechanical oscillator. The manufacturing method of the surface-mounted micro-electromechanical oscillator of the present invention includes the following steps: a. Cleaning and etching S1; b. Electroplating S2; c. Glue filling S3; d. Sealing and curing S4; e. wafer bonding S5; f. cutting S6; the steps will be described in more detail below:

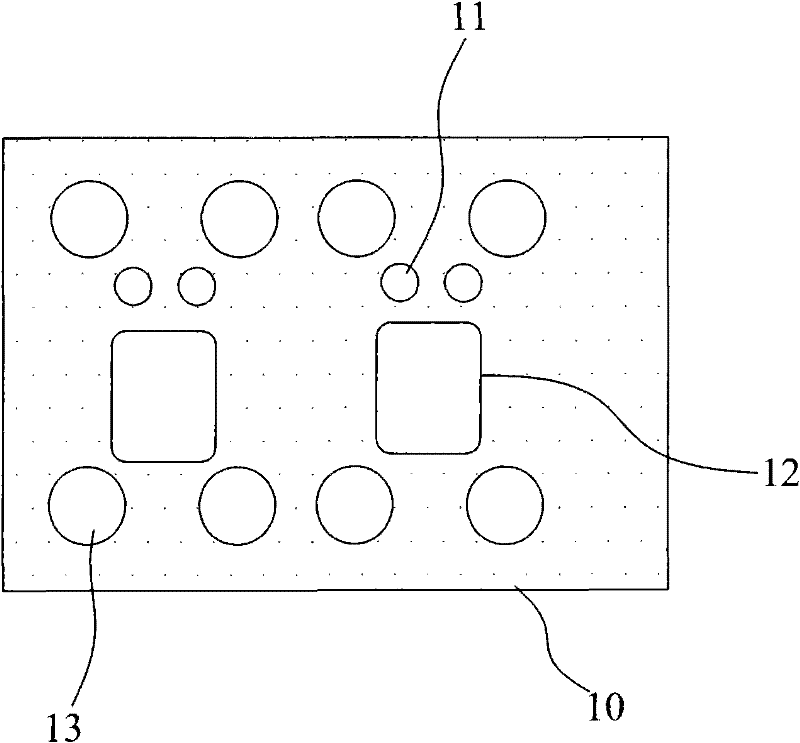

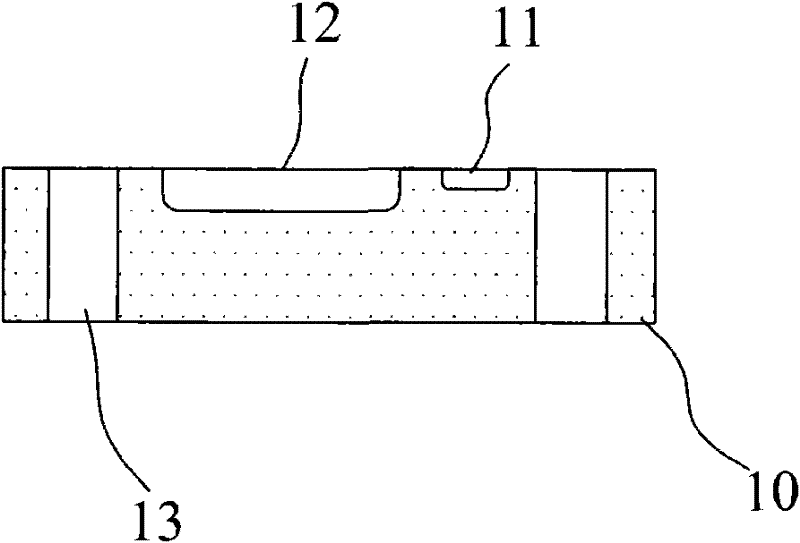

[0054] a. Clean etch S1, see also Figure 2A and Figure 2B , Figure 2A Complete front view for etch of glass wafer substrate base, Figure 2B The side view of the etching of the glass wafer substrate base is completed. As shown in the figure, the photoresist (Coating Photoresist) is etched on the cleaned glass wafer base base 10 of 3 to 8 inches or more and several diameters are etched. A hole 13 of about 100um to 150um, a plurality of fixed grooves 11 with a diameter of about 10um and a depth of about 3 to 5um, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com