Pressure sensitive adhesive for polaroid

A pressure-sensitive adhesive and polarizer technology, applied in optics, adhesives, optical components, etc., can solve problems such as poor product durability, poor fit or display, pollution, etc., to reduce fluidity, improve stability, and improve optical performance. The effect of poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

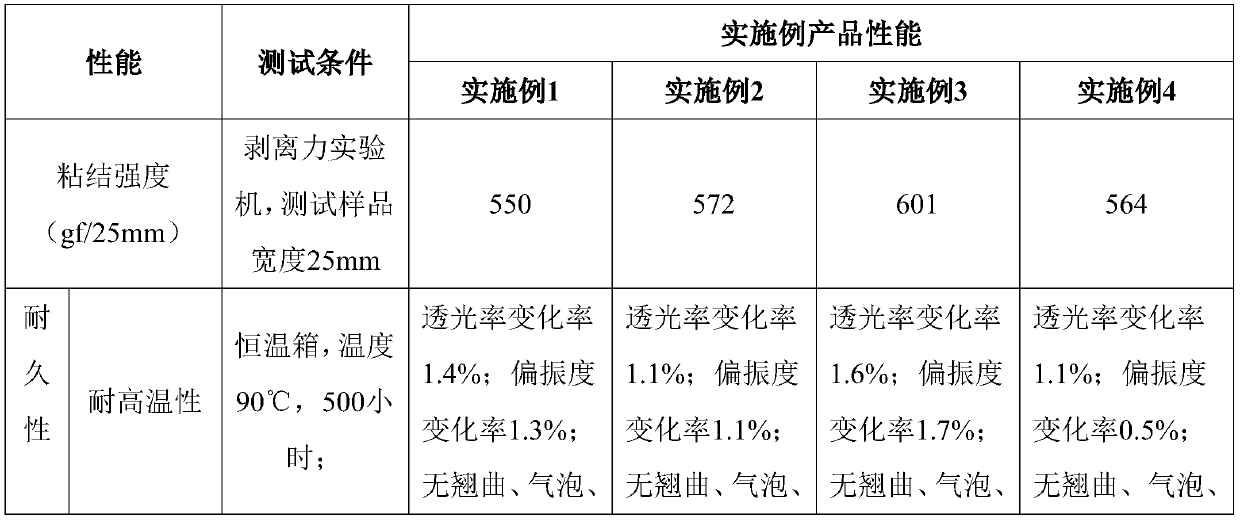

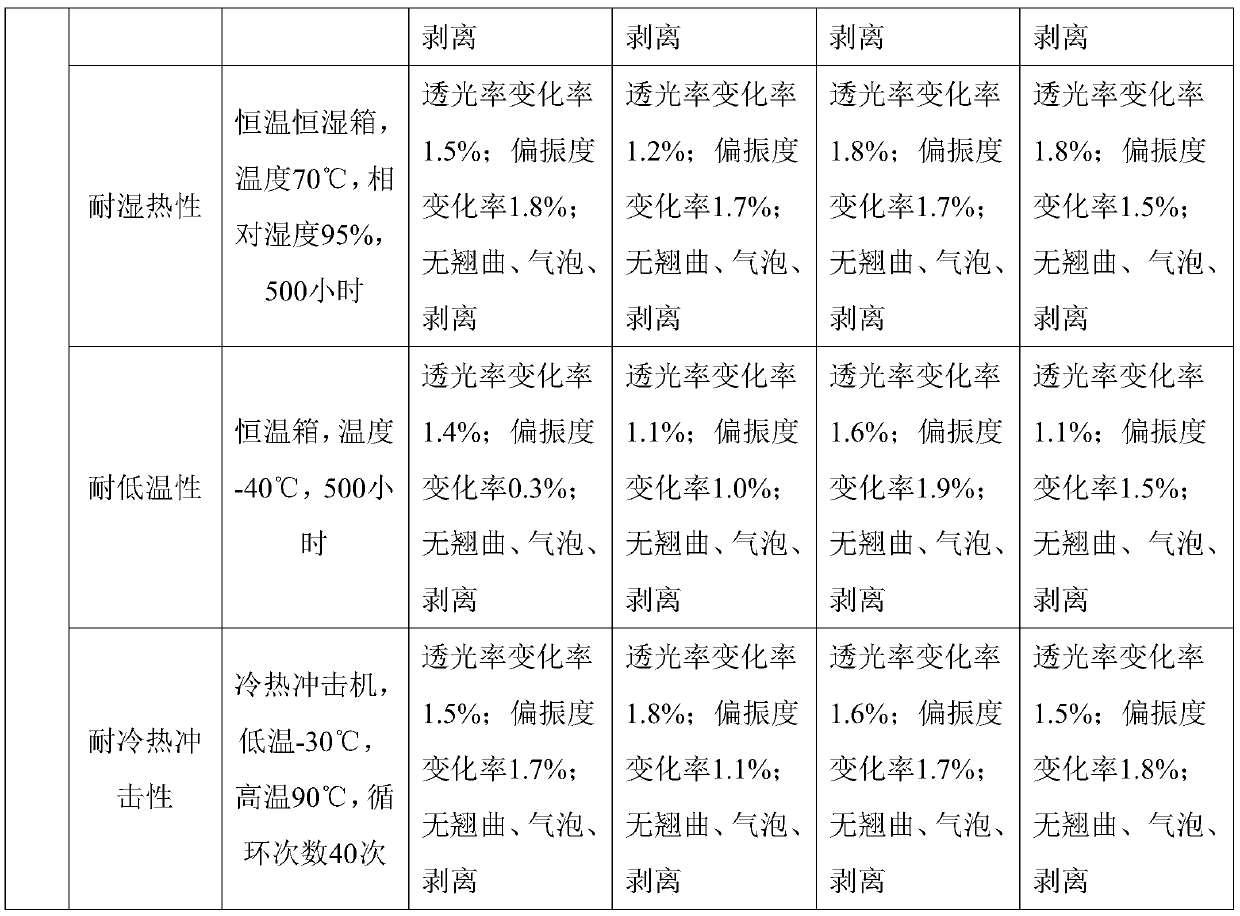

Examples

Embodiment 1

[0018] The pressure-sensitive adhesive for the polarizer of the present embodiment, the composition of each component by mass percentage is:

[0019] (1) 16 wt% acrylate copolymer, the copolymer monomers are methyl methacrylate and methyl acrylate, purchased from Japan Saiden Chemical Co., Ltd., and the degree of polymerization is 1500.

[0020] (2) 2wt% acrylate, which is a mixture of n-butyl acrylate and methyl acrylate in a mass ratio of 2.5:1;

[0021] (3) 0.1wt% modifier, the modifier is acrylic modified polysiloxane, purchased from Jiande Polymer New Material Co., Ltd.

[0022] (4) 81.9wt% diluent, which is a mixture of ethyl acetate and toluene in a mass ratio of 2:1.

Embodiment 2

[0024] The pressure-sensitive adhesive for the polarizer of the present embodiment, the composition of each component by mass percentage is:

[0025] (1) 25wt% acrylate copolymer, the copolymer monomers are methyl acrylate and hydroxyethyl methacrylate, purchased from Japan Saiden Chemical Co., Ltd., and the degree of polymerization is 2000;

[0026] (2) 3wt% acrylate, which is a mixture of n-butyl acrylate and ethyl acrylate in a mass ratio of 3:1;

[0027] (3) 0.4wt% modifier, which is carboxy-modified polysiloxane, purchased from Shenzhen Xinya New Material Co., Ltd.;

[0028] (4) 71.6wt% diluent, which is a mixture of toluene and n-hexane in a mass ratio of 1:1.5.

Embodiment 3

[0030] The pressure-sensitive adhesive for the polarizer of the present embodiment, the composition of each component by mass percentage is:

[0031] (1) 30 wt% acrylate copolymer, the copolymer monomers are methyl acrylate, acrylic acid and hydroxyethyl methacrylate, purchased from Japan Saiden Chemical Co., Ltd., and the degree of polymerization is 3500.

[0032] (2) 1.5wt% acrylate, which is a mixture of 2-methyl methacrylate, n-butyl acrylate and ethyl acrylate in a mass ratio of 1:1:2;

[0033] (3) 0.6wt% modifier, which is epoxy-modified polysiloxane, purchased from Anhui Aiyota Silicone Oil Co., Ltd.

[0034] (4) 67.9 wt% diluent, which is a mixture of toluene, n-hexane and acetone in a mass ratio of 1:1:4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com