Application of compound 2,4-dyhydroxyl-5-methyl-acetophenone separated and prepared with fermentation broth of Polyporus picipes

A technology of porous bacteria and fermentation broth, which is applied in the fields of chemicals, applications, and fungicides for biological control. Simple and easy, short fermentation time, mild culture conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

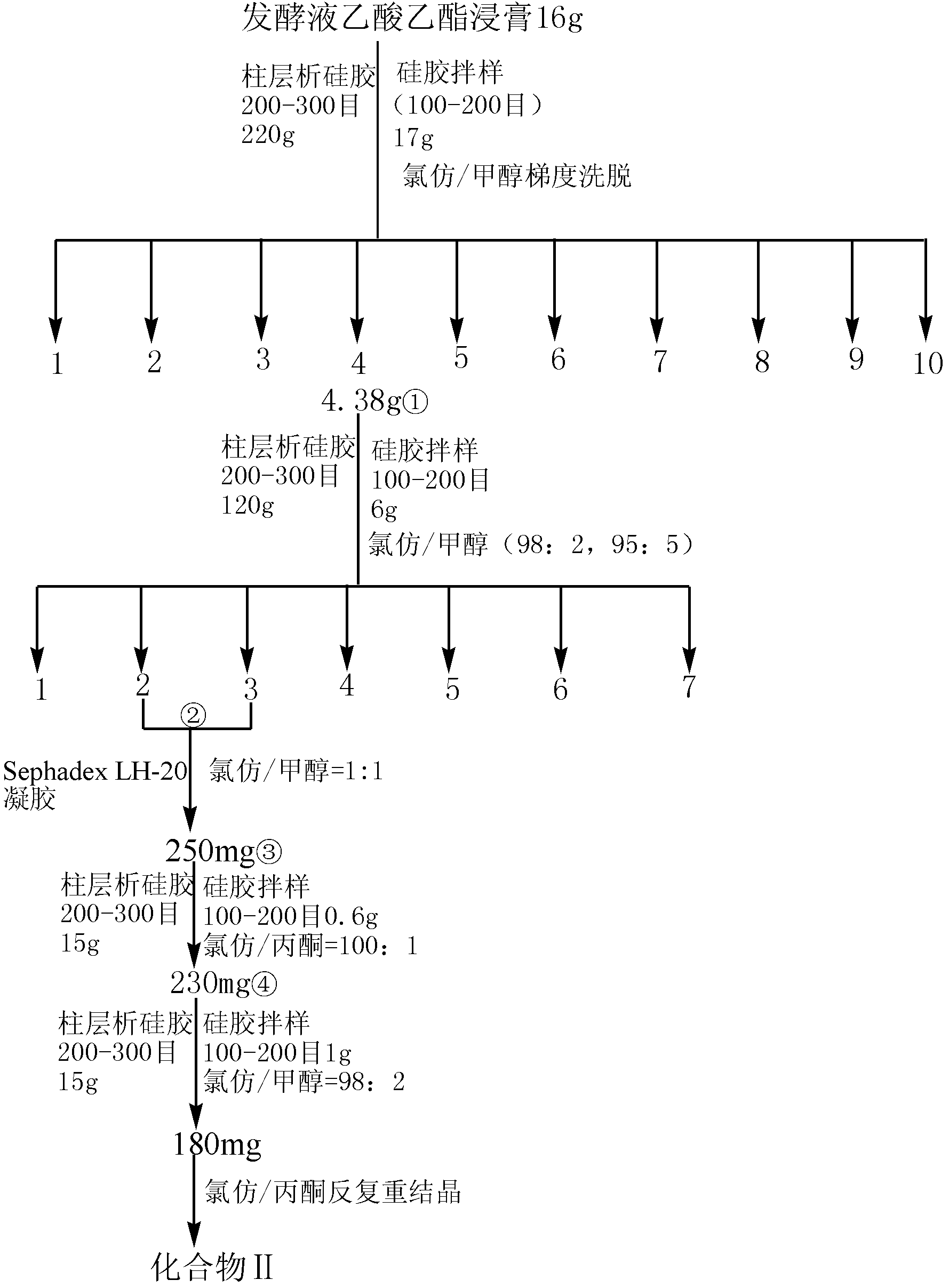

Method used

Image

Examples

preparation Embodiment 1

[0033] This embodiment adopts a liquid culture method in a plate rotating flask, and the specific steps are as follows:

[0034] 1) Fermentation of strains and concentration of fermentation broth

[0035] Take 8~10 mm from the activated solid plate strain (28℃, culture for 5~6d) 2 2~3 pieces of large and small bacteria cakes are connected to a liquid PDA medium made of peeled potatoes 200g / L, glucose 20g / L, distilled water 1000mL, pH 7.2 or so, sterilized at 121°C for 30 minutes (liquid volume is 50mL / In a 150mL Erlenmeyer flask), incubate for 3 to 4 days on a rotating shaker (rotation speed: 150r / min) at 28°C to form bacteria balls and transfer them to the fermentation flask with a 10% inoculum amount (liquid volume is 150mL / 500mL) Erlenmeyer flask), fermented for 13 days to obtain 50L of fermentation broth. Concentrate 50L of fermentation broth at 55°C under reduced pressure and halve;

[0036] 2) Preparation of crude extract

[0037] The fermented product concentrate was extract...

preparation Embodiment 2

[0045] This embodiment adopts the method of liquid culture in a plate rotating flask, and the specific steps are as follows:

[0046] 1) Fermentation of strains and concentration of fermentation broth

[0047] Take 6~8mm from the activated solid plate strain (25℃, culture for 6~7d) 2 Three to four large and small bacterial cakes are connected to a liquid PDA medium made of peeled potatoes 180g / L, glucose 18g / L, distilled water 1000mL, pH 7.2 or so, sterilized at 121°C for 30 minutes (liquid volume is 50mL / In a 150mL Erlenmeyer flask), incubate at 25°C on a rotating shaker (rotational speed: 130r / min) for 4 to 5 days to form bacterial pellets and transfer to a fermentation flask with a 10% inoculum volume (liquid volume is 130mL / 500mL Erlenmeyer flask), fermented for 14 days to obtain a total of 10L of fermentation broth. Concentrate 10L of fermentation broth at 55°C under reduced pressure and halve;

[0048] 2) Preparation of crude extract

[0049] The fermented product concentrate...

preparation Embodiment 3

[0053] This embodiment adopts the method of liquid culture in a plate rotating flask, and the specific steps are as follows:

[0054] 1) Fermentation of strains and concentration of fermentation broth

[0055] Take 6~8mm from the activated solid plate strain (30℃, cultivate for 4~5d) 2 2~3 pieces of large and small bacteria cakes are inserted into the liquid PDA culture medium made of peeled potato 250g / L, glucose 25g / L, distilled water 1000mL, pH 7.2, and sterilized at 121°C for 30 minutes (filling volume is 50mL / 150mL Erlenmeyer flask), incubate at 34°C on a rotary shaker (170r / min) for 3 to 4 days to form bacteria pellets and transfer to the fermentation flask at a 10% inoculum (liquid volume 170mL / 500mL Erlenmeyer flask ), fermented for 11 days, a total of 15L of fermentation broth was obtained. Concentrate 15L of fermentation broth at 55°C under reduced pressure and halve;

[0056] 2) Preparation of crude extract

[0057] The fermented product concentrate was extracted with et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com