Method for efficiently synthesizing trichlorosucrose

A high-efficiency technology for sucralose, applied in the field of high-efficiency synthesis of sucralose, can solve the problems of low product purity, low efficiency and low conversion rate, and achieve the effects of high product purity, high selectivity and less organic reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Sucralose was synthesized as follows:

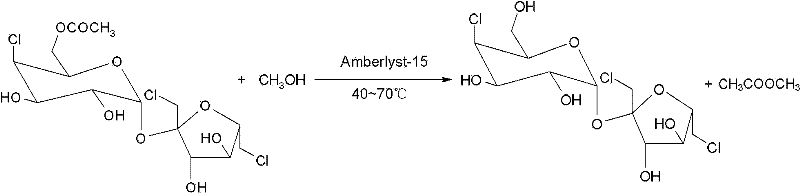

[0016] (1) Alcoholysis: put 25g of sucralose-6-ethyl ester, 50g of methanol, 1.5g of wet Amberlyst-15 into a 250mL reaction bottle, and react at 45°C for 5h; the specific reaction chemical equation is as follows:

[0017]

[0018] (2) Post-treatment: After the reaction is finished, adjust the pH of the reaction solution to 7 and filter, then decolorize with activated carbon and evaporate methanol in a vacuum to obtain a dark red slurry, add anhydrous methanol to heat and dissolve, cool to 5°C, and After standing overnight, 21.2 g of sucralose was obtained after crystallization and purification. After testing, the purity was ≥99%, and the yield was about 84.8%.

Embodiment 2

[0020] Sucralose was synthesized as follows:

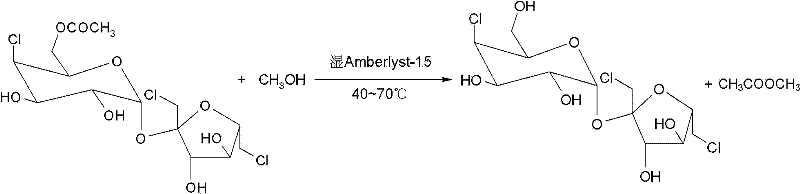

[0021] (1) Alcoholysis: Add 25g of sucralose-6-ethyl ester, 50g of methanol, and 1.5g of recovered wet Amberlyst-15 into a 250mL reaction bottle, and react at 45°C for 5h; the specific reaction chemical equation is as follows:

[0022]

[0023] (2) Post-treatment: After the reaction is finished, adjust the pH of the reaction solution to 7 and filter, then decolorize with activated carbon and evaporate methanol in a vacuum to obtain a dark red slurry, add anhydrous methanol to heat and dissolve, cool to 5°C, and After standing overnight, 20.9 g of sucralose was obtained after crystallization and purification. After testing, the purity of the product was ≥99%, and the yield was about 83.6%.

Embodiment 3

[0025] Sucralose was synthesized as follows:

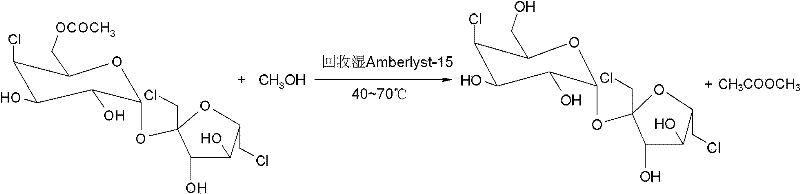

[0026] (1) Alcoholysis: add 25g of sucralose-6-ethyl ester, 50g of methanol, and 1.2g of dry Amberlyst-15 into a 250mL reaction bottle, and react at 45°C for 5h; the specific reaction chemical equation is as follows:

[0027]

[0028] (2) Post-treatment: After the reaction is finished, adjust the pH of the reaction solution to 7 and filter, then decolorize with activated carbon and evaporate methanol in a vacuum to obtain a dark red slurry, add anhydrous methanol to heat and dissolve, cool to 5°C, and After standing overnight, 21.1 g of sucralose was obtained after crystallization and purification. After testing, the purity was ≥99%, and the yield was about 84.4%.

[0029] Practice has proved that, compared with the prior art, the method for synthesizing sucralose of the present invention has simple process and mild reaction conditions; the purity of the products is above 99%, which is higher than that of the prior art above 98...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com