Special PA6 injection molding material used for direct injection molding and preparation method thereof

A special material and direct technology, applied in the field of polymer engineering materials, can solve the problems of rising product cost, reduced mechanical properties, poor fluidity of PA6, etc., and achieve the effects of beautiful appearance, moderate process conditions and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

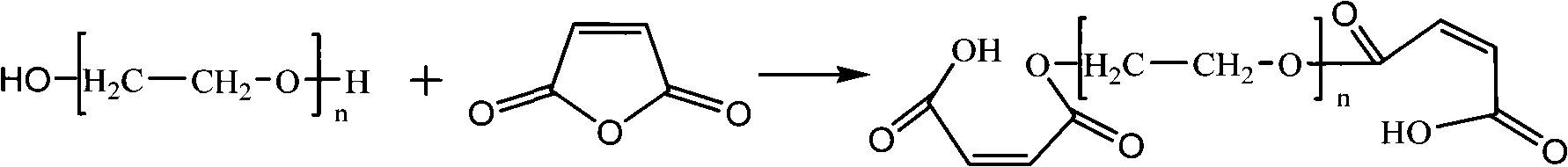

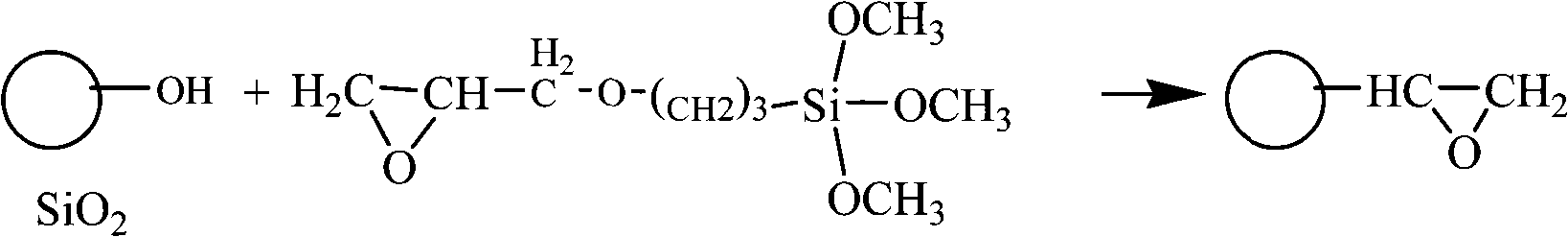

[0032] Using PA6 as the base resin, using maleic anhydride grafted polyethylene glycol (MPEG) as the plasticizer, and using silane coupling agent to graft nano-SiO 2 As the enhancer, 3,5-di-tert-butyl-4-hydroxyphenylpropionyl-hexamethylenediamine (antioxidant 1098) and tris(2,4-di-tert-butylphenol) phosphite) (antioxidant Agent 168) is an antioxidant, and the mass ratio of antioxidant 1098 to antioxidant 168 is 1:1. The mix of materials is shown in Table 1.

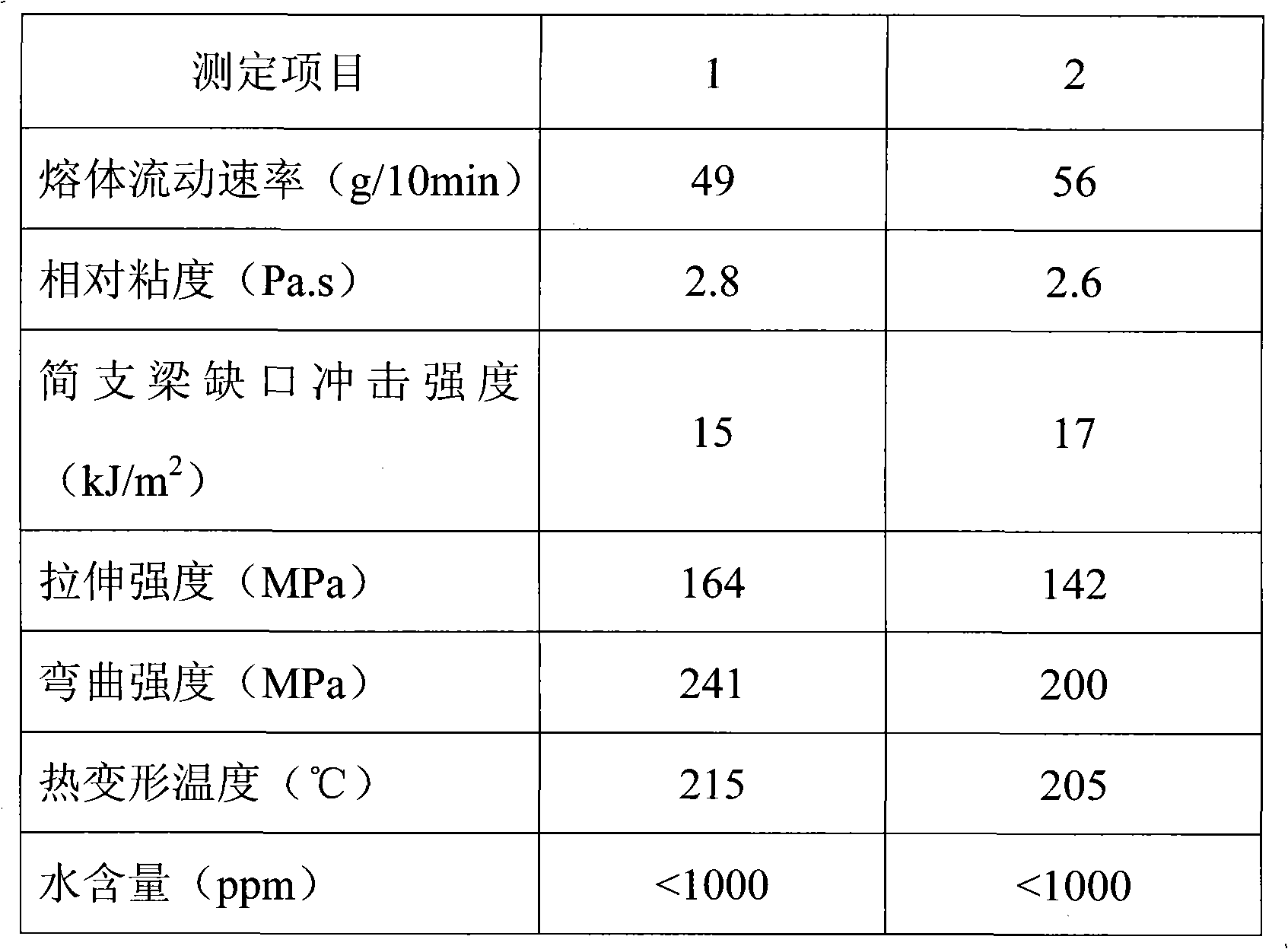

[0033] Weigh and remove the silane coupling agent grafted nano-SiO 2 For other materials, mix them in the mixer for 3 to 5 minutes, and then feed the uniformly mixed materials into the twin-screw extruder, in which the silane coupling agent is grafted with nano-SiO 2 Add from the first exhaust port, the temperature from the feeding port to the extrusion die is 160-180°C, 190-220°C, 210-240°C, 220-250°C, 210-240°C, and the speed of the main engine is 30 ~40Hz, sample with plastic injection molding machine. The properti...

Embodiment 3 and 4

[0035] Add caprolactam monomer into the high-pressure reactor, and add various additives at the same time, including plasticizer maleic anhydride grafted polyethylene glycol (MPEG), reinforcing agent silane coupling agent grafted nano-SiO 2 , antioxidants, water and adipic acid. Antioxidant is antioxidant 1098 and antioxidant 168, and its mass ratio is 1:1. The mix of materials is shown in Table 3.

[0036] After feeding in the autoclave, the temperature is raised from room temperature to 200-210°C, the pressure reaches 0.8MPa, the hydrolysis ring-opening reaction is performed for 2 hours, and the temperature is raised to 250-260°C, the pressure is 0.6-0.7MPa, and the chain is extended for 2 hours. After the reaction is completed, the material is discharged in a water bath and granulated. The properties of the product materials are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com