Method for producing electrochemical luminous electrode

A light-emitting electrode and electrochemical technology, which is applied in the field of preparation of electrochemiluminescent electrodes, can solve the problems of complex structure of the measurement device, complicated control units, and reduced measurement sensitivity, and achieve simplified flow path components, mixing device components, detection Sensitivity improvement, direct effect of electron transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing an electrochemiluminescence electrode, comprising the steps of:

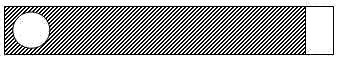

[0032] (1) The ITO glass plate is used as the basic electrode. The ITO glass plate is a strip of 4cm′7mm. The insulating material is laid on its conductive surface. A round hole with a diameter of 5mm is left at one end of the ITO glass plate as the electrode area. Leave 2mm as connection area, see attached figure 1 As shown, the electrode area is located inside the insulating material; after completion, use dilute ammonia water, secondary water, ethanol, and secondary water to ultrasonically clean for 15 minutes each, and dry for later use;

[0033] (2) chitosan is dissolved in acetic acid of 0.05mol / L, is mixed with the chitosan solution that mass concentration is 0.1%;

[0034] The carbon nanotubes are ultrasonically treated in concentrated nitric acid and washed and dried before use, and then the carbon nanotubes are ultrasonically dispersed in the chitosan solution at a mass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com