Bean dreg peach slice cake and preparation method thereof

A technology of peach sliced cake and bean dregs, which is applied in the preparation of peach sliced cake and the field of peach sliced cake containing bean dregs, which can solve the problems of not meeting consumer demand, easily causing obesity, and single taste, so as to improve diet structure and improve compatibility sex, nutritional enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

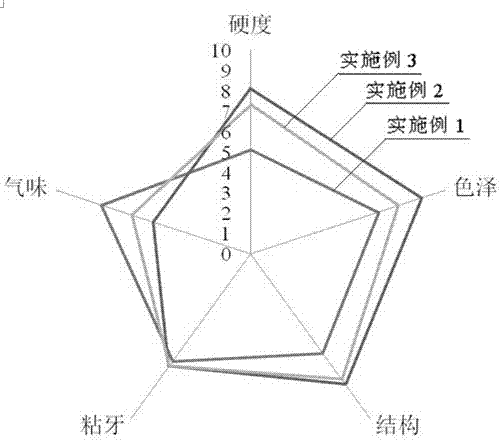

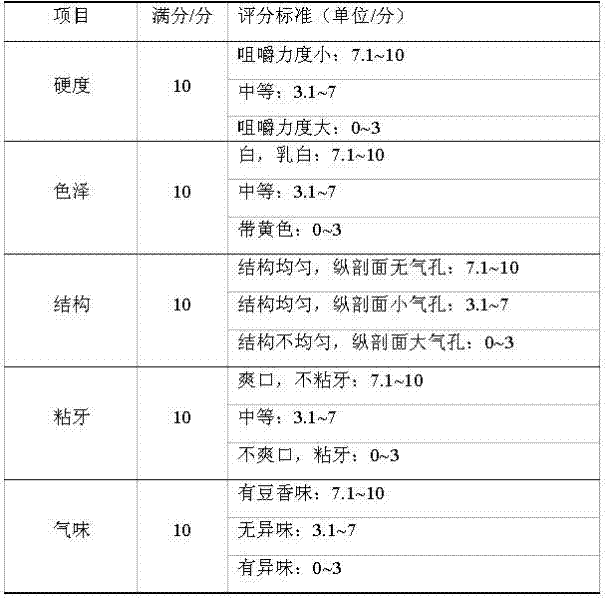

Embodiment 1

[0032] Example 1 Peach Slice Cake with Bean Dregs

[0033] 1 recipe

[0034] Weigh the raw materials according to the following parts by weight (kg);

[0035] Glutinous rice 3, white sugar 1.8, maltose 0.09, sesame oil 0.18, walnut kernel 0.6, bean dregs powder 1.5;

[0036] Described okara powder is made by the method 1 of embodiment 1.

[0037] 2 Preparation method

[0038] The specific steps are:

[0039] 1) Frying and crushing of glutinous rice: After sifting the glutinous rice to remove impurities and broken rice, weigh 3kg, wash it in water at 50-60°C for about 8-15 minutes, transfer it to the pot, cover it and cover it for 15 minutes. -20 minutes, pick up and drain, then stir-fry until the glutinous rice is fully cooked, then grind the fried glutinous rice into a fine powder with a high-speed crushing machine, pass through a 100-mesh sieve, and then put the sieved powder in a separate Spread out on the board to absorb water and regain moisture for 3 days (25°C) t...

Embodiment 2

[0045] Example 2 Peach Slice Cake with Bean Dregs

[0046] 1 recipe

[0047] Weigh the raw materials according to the following parts by weight (kg);

[0048] Glutinous rice 7, white sugar 4.2, maltose 0.21, sesame oil 0.42, walnut kernel 1.4, bean dregs powder 0.7;

[0049] Described bean dregs powder is made by the method 2 of embodiment 1.

[0050] 2 Preparation method

[0051] The specific steps are:

[0052] 1) Frying and crushing of glutinous rice: After the glutinous rice is sieved to remove impurities and broken rice, weigh 7kg, wash it in water at 50-60°C for about 8-15 minutes, transfer it to a pot, cover it and cover it for 15 minutes. -20 minutes, pick up and drain, fry over high heat until the glutinous rice is fully cooked, then grind the fried glutinous rice into a fine powder with a high-speed grinding machine, pass through a 100-mesh sieve, and then put the sieved powder in the Spread out on the partition to absorb water and regain moisture for 3 days (25...

Embodiment 3

[0058] Example 3 Bean Dregs and Peach Slice Cake

[0059] 1 recipe

[0060] Weigh the raw materials according to the following parts by weight (kg);

[0061] Glutinous rice 5, white sugar 3, maltose 0.15, sesame oil 0.3, walnut kernel 1, bean dregs powder 1;

[0062] Described okara powder is made by the method 1 of embodiment 1.

[0063] 2 Preparation method

[0064] The specific steps are:

[0065] 1) Frying and crushing of glutinous rice: After sieving the glutinous rice to remove impurities and broken rice, weigh 5kg, wash it in water at 50-60°C for about 8-15 minutes, transfer it to the pot, cover it and cover it for 15 minutes. -20 minutes, pick up and drain, fry over high heat until the glutinous rice is fully cooked, then grind the fried glutinous rice into a fine powder with a high-speed grinding machine, pass through a 100-mesh sieve, and then put the sieved powder in the Spread out on the partition to absorb water and regain moisture for 3 days (25°C) to get ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com