Composite microbial seaweed organic liquid fertilizer and preparation method thereof

A technology of compound microorganisms and liquid fertilizers, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of low fertility, poor effect, and long production cycle, so as to stimulate the growth and development of crops, improve resource utilization, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

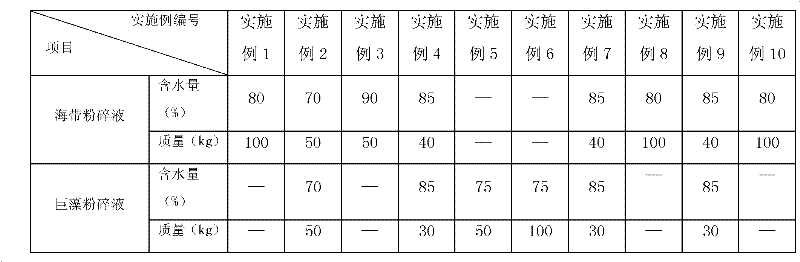

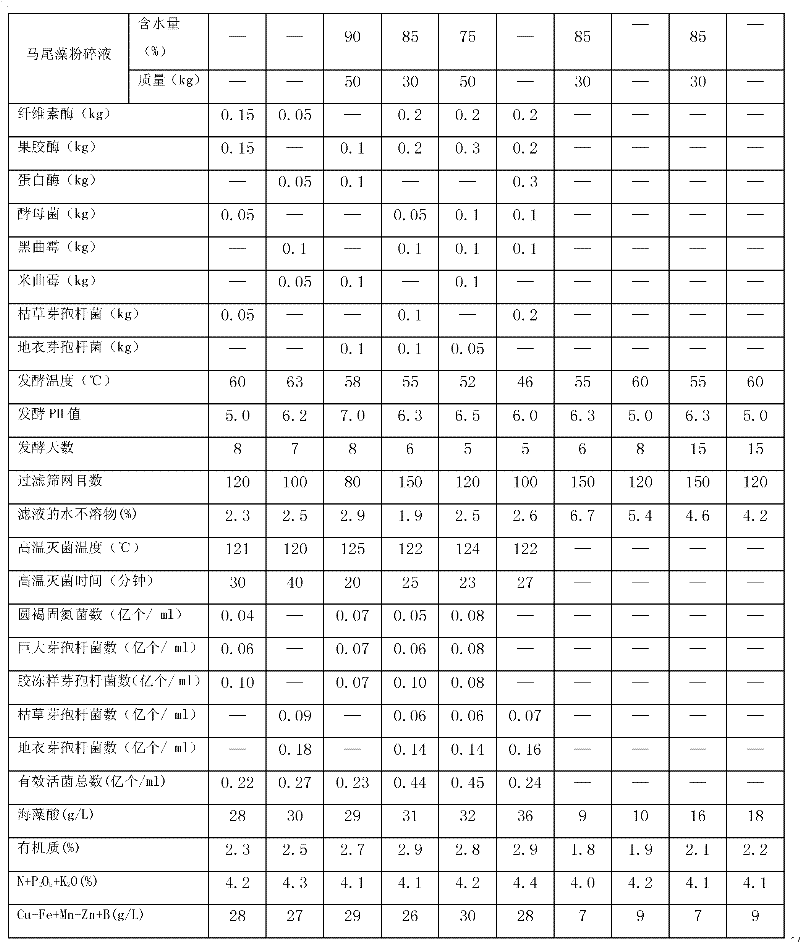

[0026] The present invention will be further described below in conjunction with specific examples, but not as a limitation to the present invention.

[0027] The preparation of the compound microbial bright seaweed organic liquid fertilizer of the present invention specifically comprises the following steps:

[0028] (1) Batching treatment: 0.1-0.6 mass parts of compound enzyme and 0.1-0.4 mass parts of biological leavening agent are added to 100 mass parts of seaweed pulverized liquid with a water content of 70%-90%, and mixed;

[0029] (2) Aerobic fermentation: put the ingredients obtained in step (1) into a fermenter, and ferment aerobically for 5-8 days at a temperature of 40-60° C. and a pH of 5-7 to obtain a fermented liquid;

[0030] (3) Filtration: filter the fermented liquid obtained in step (2) to obtain the filtrate;

[0031] (4) high-temperature sterilization: the filtrate obtained in step (3) was sterilized at 120-125° C. for 20-40 minutes;

[0032] (5) compoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com