Method for quickly and continually preparing powdery caramel pigment by using spray drying technology

A caramel color, powder technology, applied in the direction of organic dyes, etc., to achieve the effect of easy product quality, short preparation time and process, and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

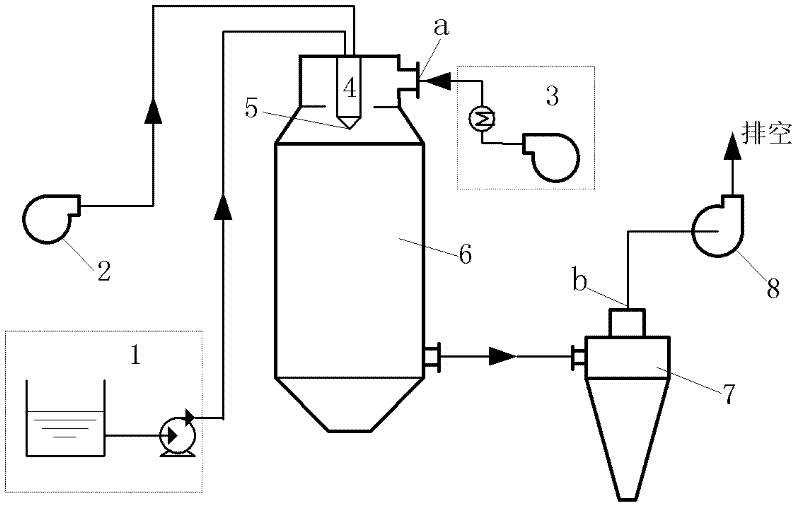

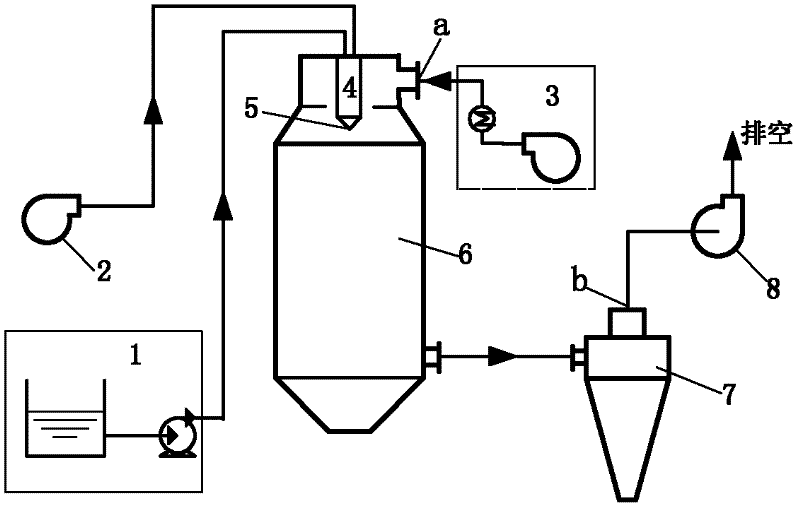

Method used

Image

Examples

Embodiment 1

[0029] Take 1kg of glucose sample, add 2kg of distilled water to shake and mix and fully dissolve; then add 0.5kg of NH 4 Cl, to get glucose and NH 4Cl mixed solution, the mixed solution is pumped into the atomizer in the spray drying equipment with a peristaltic pump. The spray reaction conditions are as follows: the hot air inlet temperature is 270°C; the flow rate of the hot air entering the drying equipment is set at 1m3 / min; the flow rate of the mixed liquid pumped into the spray drying equipment is set at 30mL / min; The length of the heat preservation flow channel (12 cm in diameter) is 15 cm, the reaction time is 3 seconds, and the outlet temperature is 145° C. After the spray-drying reaction treatment, the water content in the Maillard product is measured to be 0.4% by mass; the obtained reactant is then fluidized and vibrated-dried to obtain a powdery caramel pigment product. Dissolve 0.01g of caramel pigment product in 10mL of distilled water, measure the absorbance...

Embodiment 2

[0031] Take 1 kg of fructose sample, add 6 kg of distilled water to shake and mix and fully dissolve; then add 0.1 kg (NH4)2SO4 to obtain a mixed solution of fructose and (NH4)2SO4, which is pumped into the spray drying equipment with a peristaltic pump for atomization device. The spray reaction conditions are as follows: the hot air inlet temperature is 250°C; the flow rate of hot air entering the drying equipment is set to 0.3m3 / min; the flow rate of the mixed liquid pumped into the spray drying equipment is set to 20mL / min; The length of the heat preservation channel (12 cm in diameter) is 1 m, the measured reaction time is 10 seconds, and the measured outlet temperature is 135° C. After the spray-drying reaction treatment, the water content in the Maillard product is measured to be 0.6% by mass; the obtained reactant is then fluidized and vibrated-dried to obtain a powdery caramel pigment product. Dissolve 0.01g of caramel pigment product in 10mL of distilled water, and m...

Embodiment 3

[0033] Take 1 kg of galactose sample, add 30 kg of distilled water to vibrate, mix and fully dissolve, then add 0.25 kg of urea to obtain a mixed solution of galactose and urea, and pump the mixed solution into the atomizer in the spray drying equipment with a continuous constant flow pump. The spray reaction conditions are as follows: the hot air inlet temperature is 230°C; the flow rate of hot air entering the drying equipment is set at 0.2m3 / min; the flow rate of the mixed liquid pumped into the spray drying equipment is set at 15mL / min; The length of the heat preservation channel (12 cm in diameter) is 1.5 m, the measured reaction time is 25 seconds, and the measured outlet temperature is 120° C. After the spray-drying reaction treatment, the water content in the Maillard product is measured to be 0.8% by mass; the obtained reactant is then fluidized and vibrated-dried to obtain a powdery caramel pigment product. Dissolve 0.01g of caramel pigment product in 10mL of distill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com